Kyocera TASKalfa 3051ci User manual

Other Kyocera Printer manuals

Kyocera

Kyocera FS-C5015N User manual

Kyocera

Kyocera C5020N - FS Color LED Printer User manual

Kyocera

Kyocera EP C170N User manual

Kyocera

Kyocera DP-5130 User manual

Kyocera

Kyocera FS 1030D - B/W Laser Printer User manual

Kyocera

Kyocera ECOSYS P5026cdw User manual

Kyocera

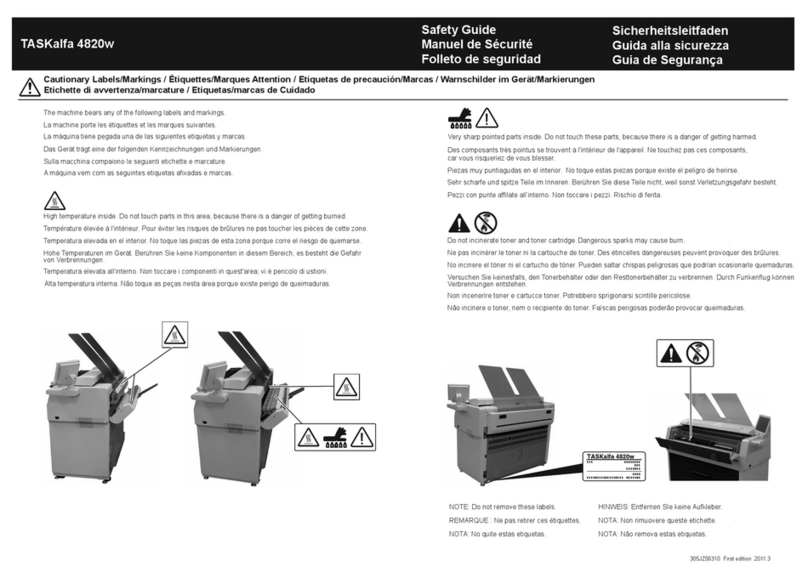

Kyocera TASKalfa 4820w Installation and operating manual

Kyocera

Kyocera FS-C5020N User manual

Kyocera

Kyocera ECOSYS FS-6525MFP User manual

Kyocera

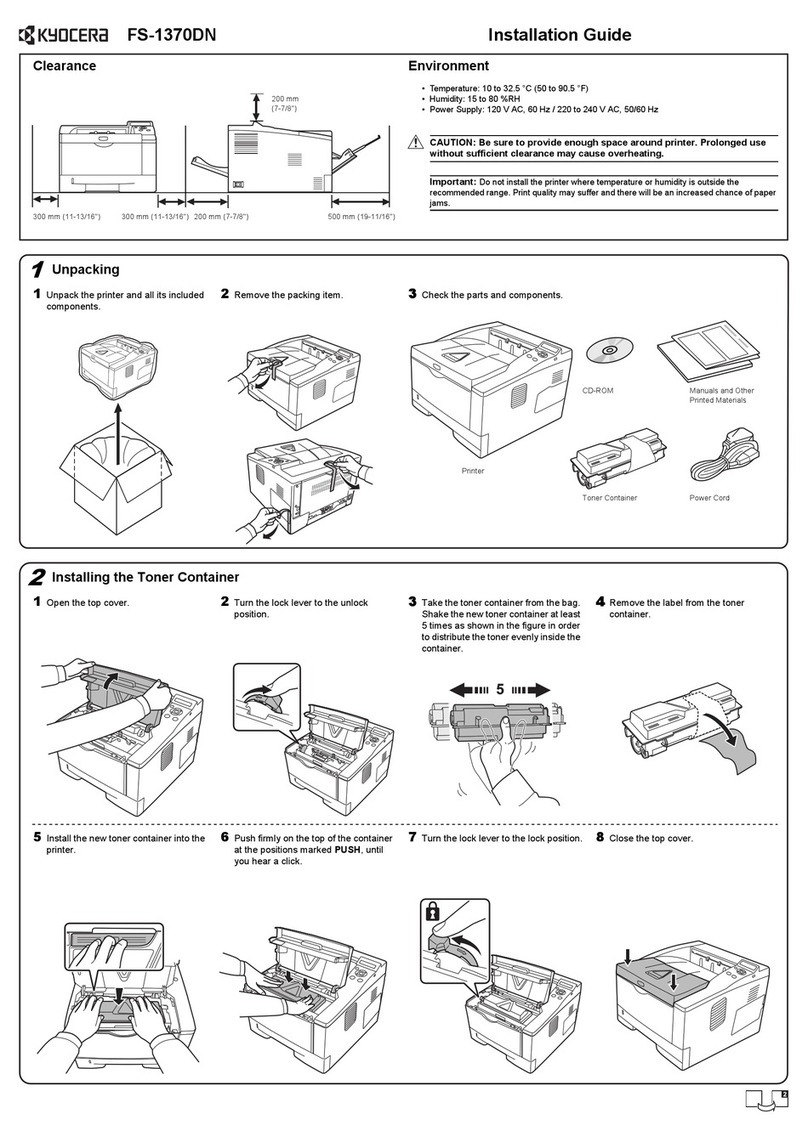

Kyocera ECOSYS FS-1370DN User manual

Kyocera

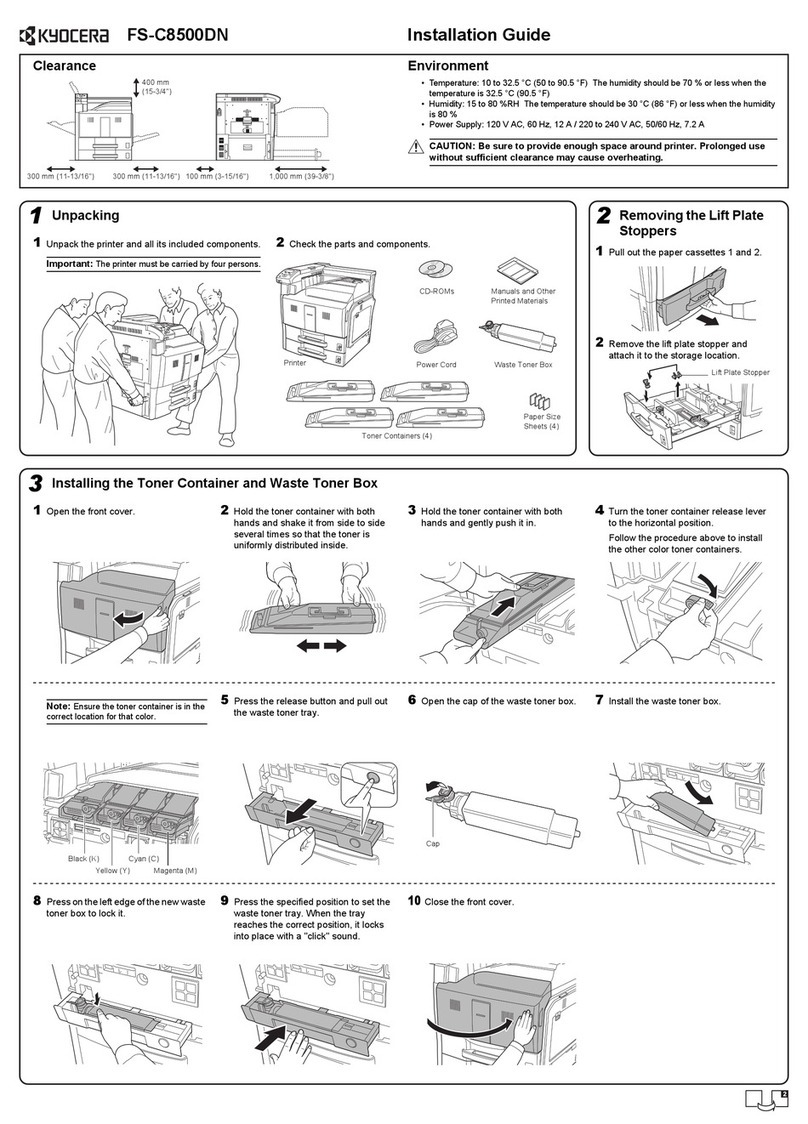

Kyocera FS FS-C8500DN User manual

Kyocera

Kyocera KM-3650W User manual

Kyocera

Kyocera KM-4530 User manual

Kyocera

Kyocera ECOSYS P4140dn User manual

Kyocera

Kyocera ECOSYS P6235cdn User manual

Kyocera

Kyocera FS-1030D User manual

Kyocera

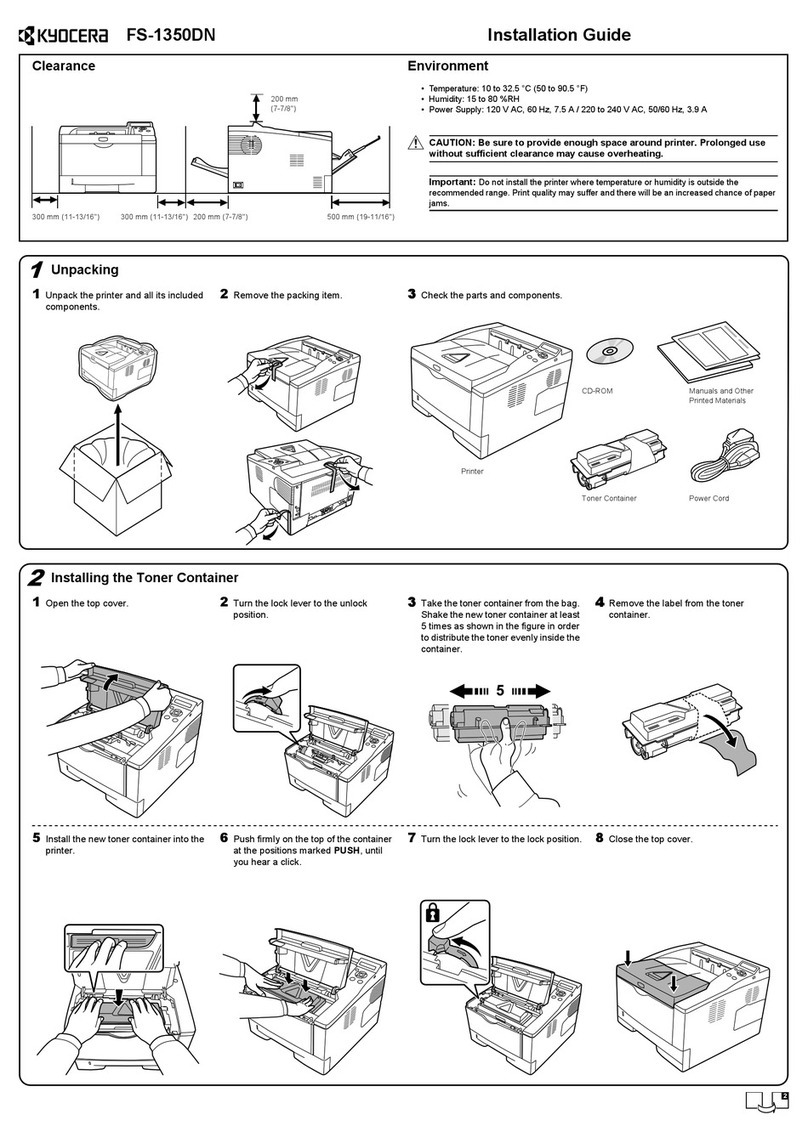

Kyocera ECOSYS FS-1350DN User manual

Kyocera

Kyocera FS-1300D User manual

Kyocera

Kyocera KM-3035 User manual

Kyocera

Kyocera FS-2000D, FS-3900DN, FS-4000DN, FS-6950DN User manual