1. Introduction

1.1 General Description of the product

1.2 Getting familiar with the equipment - Short Description

The new LALIZAS Respiratory Protective Device (of types 71327 & 71328) is a Self-contained open-circuit compressed air breathing apparatus with positive pressure full face mask. It is

an Apparatus for fire-fighting of Type 2 tested according to EN 137 (2006) and EN 136 (1998) including AC (1999) and AC (2003), ISO 23269-2:2011.Certified according latest provisions

of MED Directive 2014/90 and SOLAS requirements.

Approved for use as self-contained compressed air breathing apparatus of fire-fighter's outfit.

The apparatus is not for use in accidents with cargoes.

WARNING:

- It is not a diving apparatus!

- It is strongly recommended that the Apparatus is used by well- trained personnel and not by untrained users.

The Lalizas Self-Contained Breathing Apparatus Models (71327 & 71328) are similar products, as their main structure and operation is the same, while the only difference is in the used

cylinders providing different rated duration to the products. The Breathing Apparatus is sufficiently robust to withstand the rough usage it is likely to receive, and is designed so as to have

no protruding parts or sharp edges likely to be caught on projections in narrow passages or to be in contact with the wearer. It is designed to ensure its function in any orientation. All

materials used in the construction of the apparatus have adequate resistance to deterioration by heat and adequate mechanical strength. All demountable connections are readily

connected and secured by hand.

The product consists of six main components as described in short below:

a) Back frame: Incorporates donning cushion harness for convenient fitting, adjustable cylinder holding Velcro webbing and a rubber pad for better and stable placement of cylinder. It is

designed to allow the user to don and doff the apparatus quickly and easily without assistance and is adjustable, without slipping inadvertently. The back frame structure bears two grooves

for the high and medium pressure hoses of the pressure regulator to run in (Figure 1).

b) First Stage Regulator: The first stage regulator incorporates two pneumatic hoses, a reliable pressure indicator and a warning whistle. The pressure indicator, which is positioned to

enable to be read conveniently by wearer, shows the pressure in the pressure vessel on opening the valve, to ensure that the pressure is monitored. The Pressure Indicator is graduated

from zero mark up to 40Mpa (400Bar) and enables the wearer to estimate the pressure to within 1Mpa(10bar). It bears a fluorescent dial that allows clear reading of the pressure even in

intense dark, and a non-splintering window. The Warning Whistle is so designed that when pressure reduces below 50-60bar, it operates providing a continuous sound of pressure

level>90dB (A), warning the user that the air is dropping down. Moreover, the First Stage Regulator bears a connecting thread for the cylinder valve, which is G5/8 according to EN144-2.

For increased safety a relief valve is also incorporated (Figure 2).

c) Second Stage Regulator: The second stage regulator consists of an “on demand'' valve and a pneumatic hose (Figure 3 ). The pneumatic hose is equipped with a fast joint for easy

assembly with the first stage regulator hose. The “on demand'' valve is so designed that can be assembled with the face piece as a plug-in interface (Figure 3). The ''on demand'' valve is

equipped with ON & OFF buttons in order to allow the user to stop or start the air supply. Using these buttons the user can stop the air supply and remove the valve from the face piece while

the cylinder valve is still open (Figure 1). This special structure does not allow the provided breathing-air to escape, while it provides the user with the possibility to re-attach the “on

demand valve” to the face piece –at all times- and re-use the device without any special procedure except just breathing. Breathing will produce under pressure inside the face mask that

will force the on ''demand'' valve to open and provide breathing air again.

d) Face piece (Figure 4): The face piece is classified as Mask of Class 3+ for Special Use per EN 136:1998 + AC (2003) and as instructed in the last version of Maritime Equipment

Directive 96/98/EC. The mask is temperature, flammability and thermal radiation resistant as well as it is leak tight and consists of:

1. Introduction

1.1 General Description of the product

1.2 Getting familiar with the equipment- Short Description

1.3 Structure of the Product

1.4 Apparatus Duration

1.5 Air quality of the equipment

1.6 Operation of Self-Contained Breathing Apparatus

1.6.1 Checks prior to Use

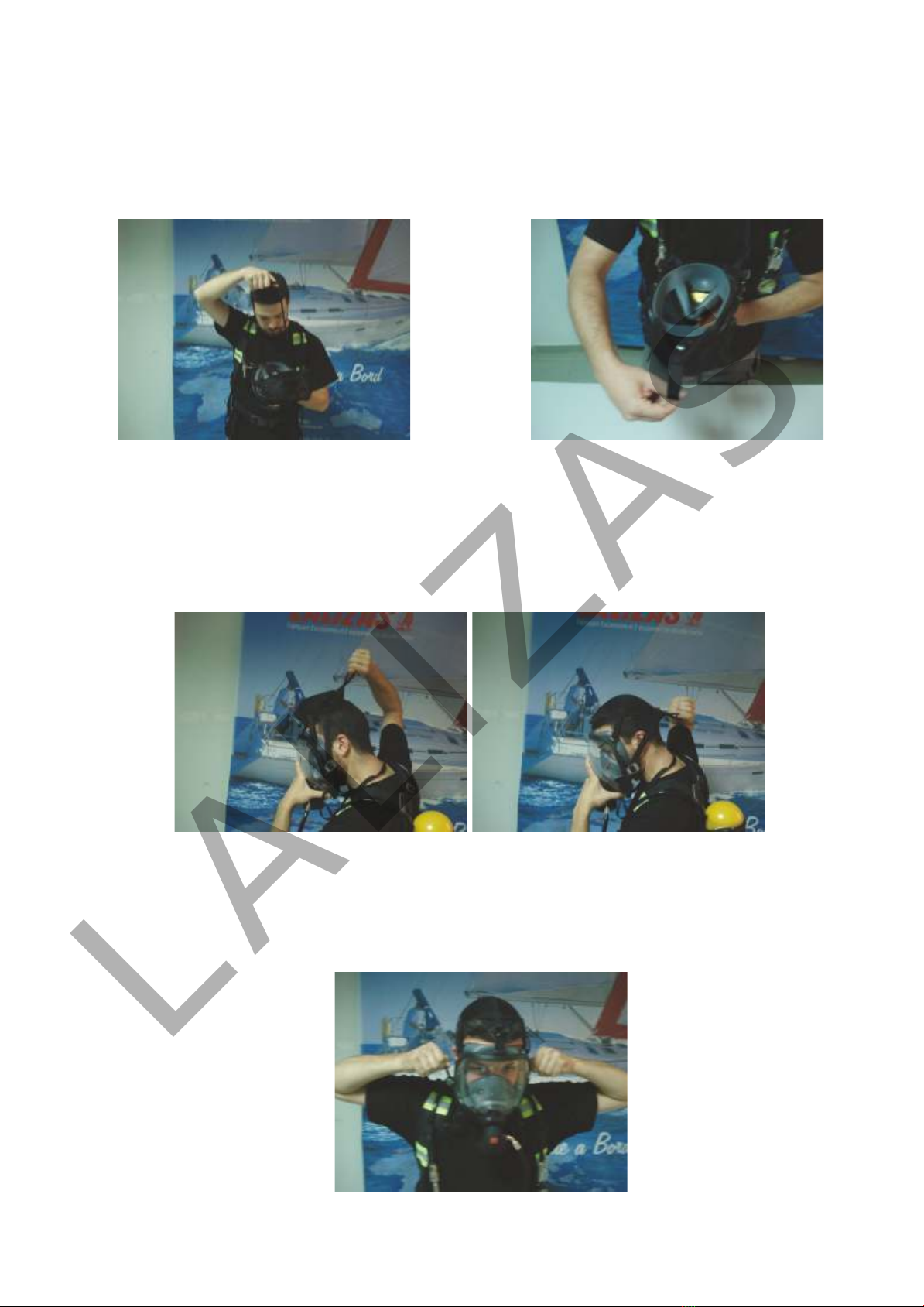

1.6.2 Fitting & Use

1.6.3 Doffing Procedure

1.6.4 After Use Procedure

1.7 Maintenance and Service Instructions

1.7.1 Cleaning, Disinfecting, Drying (A)

1.7.2 Visual Inspection (B)

1.7.3 Service (C)

1.7.4 Inspection Intervals

1.7.5 Function Test (E)

INDEX

1.8 Transportation and Storage

1.8.1 Transportation

1.8.2 Storage

1.8.3 Safety Notification

1.8.4 Life Expectancy

1.9 Technical Data of Self Contained Breathing Apparatus

SOLAS/MED 71327 & 71328

IMPORTANT NOTICE !In case you don't use LALIZAS original air cylinder for this device

Ensure that the air cylinder placed on the device is compatible and satisfies the following conditions:

The air cylinder shall be designed in accordance with national regulations.

The volume of air contained in the air cylinder shall be at least 1200 liter.

The compressed air cylinder markings shall include the charging pressure, capacity and the stamp of the authorized inspection body.

The complete apparatus shall undergo practical performance tests under realistic conditions to check for imperfections.