10

MPE SERIES PRESSURE WASHER OPERATOR’S MANUAL

LANDA MPE •Rev. 5/02

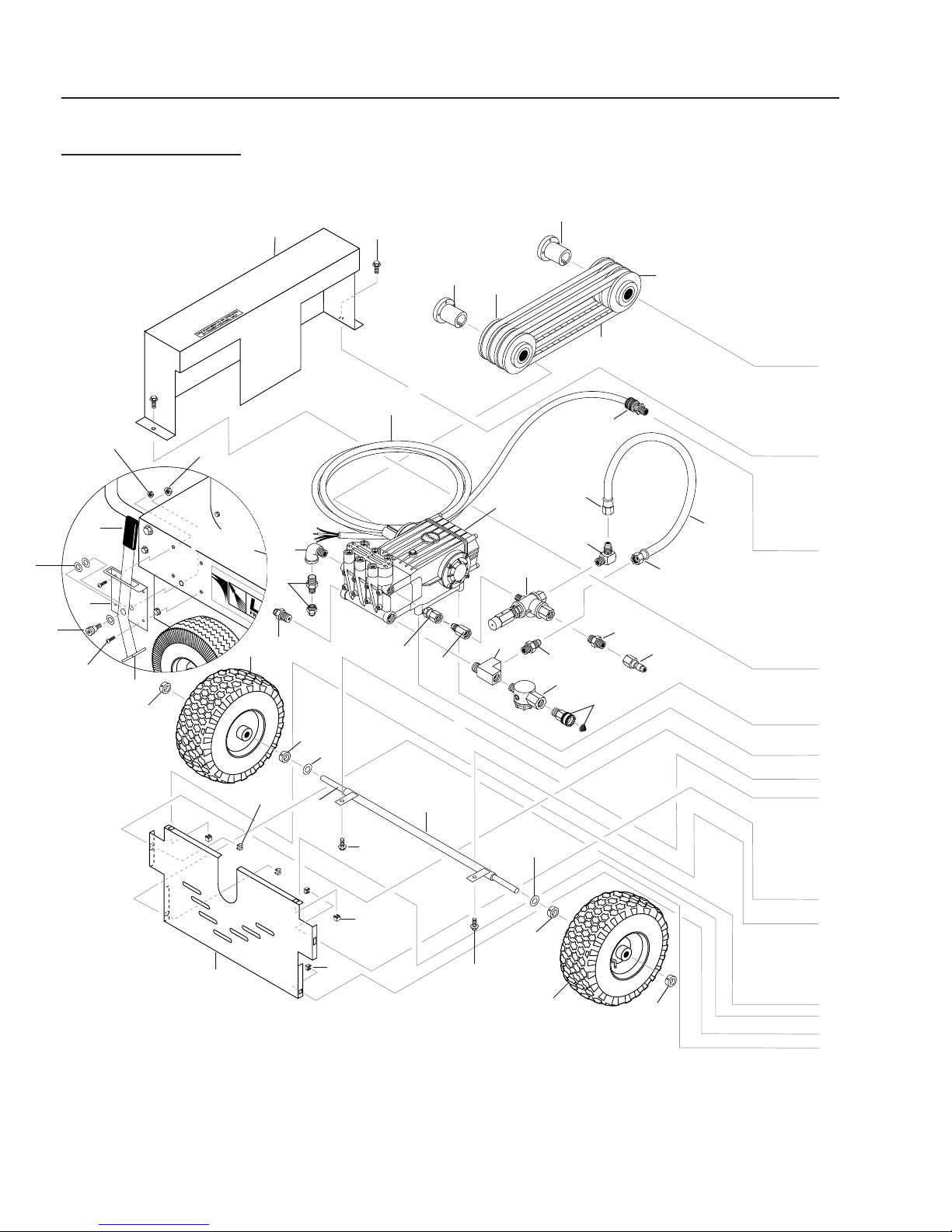

EXPLODED VIEW

MPE5-50021B, C PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 10-020MPE ▲ Label, MPE, Lexan 1

2 10-08014 ▲ Label, Landa Made in USA 1

3 10-08021 ▲ Label, Disconnect Pwr Supply2

4 10-2055000 ▲ Label, 5-5000 (Lexan) 1

5 10-99061 ▲ Label, Platinum Series W/Op.

Instr. & Warnings, Cold 1

6 2-00271 Elbow, Street, 3/8" x 1/2", Steel 1

7 2-00510 Nipple, 1/2" JIC, 3/8" Fem 1

8 2-0079 Swivel, 1/2" JIC Fem, 3/8" Mal 1

9 2-0103 Grommet, Rubber,

Nozzle Holder 5

10 2-01403 ▲ Bushing, Snap, 5/8" 1

11 2-1042 Tee, 1/2" Street 1

12 2-1053 Nipple, 1/2" JIC x 1/2" Pipe 1

13 2-1062 Elbow, 1/2" JIC x 1/2", 90 DGR 1

14 2-1923 Strainer, 1/2" PA, Inline Plastic 1

15 2-20022 Nipple, 3/8" Female 5000 PSI 1

16 2-20024 Nipple, 1/4", Female, 5000 PSI 5

17 2-0006 Nipple, 3/8" Hex Steel 1

18 2-30082 Pump Protector, 1/2" PTP 1

19 2-3408 Disk, Rupture Assy, 8000 PSI 1

2-3480 Disk Rupture Replacement

8000 PSI 1

20 4-01404500 Nozzle Only, 1/4" MEG, 004.5 1

4-01404515 Nozzle Only, 1/4" MEG 1504.5 1

4-01404525 Nozzle Only, 1/4" MEG, 2504.5 1

4-01404540 Nozzle Only, 1/4" MEG 4004.5 1

21 4-0307 Wheel, 6" Steel Rim 4

22 4-01450065 Nozzle Only, 1/4" MEG, 6550 SS1

23 5-1030 Motor, 20 HP, 3 PH, 460V, 230V,

M2515T (MPE5-50021B, C) 1

24 5-2330 Pump, General T-5050/L 1

25 5-3014 Unloader, General, 5000 PSI 1

26 5-407040 Pulley, 3TB40 Motor 1

27 5-41004501 Pulley, 3BK 45 H Pump 1

28 5-522158 Bushing P1 x 1-5/8" 1

29 5-512024 Bushing H x 24mm 1

30 5-604037 Belt, BX37 3

31 6-0109 Cord, Serv, SEO, 10/4, /Ft.

Coleman (MPE5-50021C) 19

6-0103 Cord, Serv. SO 4/4 /Ft.

Coleman (MPE5-50021B) 19

ITEM PART NO. DESCRIPTION QTY

32 6-051710 Connector, Aluminum Conduit 1

33 90-4005 Washer, 5/8", Flat, SAE 4

34 95-07141017 Belt Guard CMPL, SEHW 1

35 95-07141110 Retainer, Pump Take Up 1

36 95-07290006 Axle, Holder Assembly,

VHW/VHP 2

37 95-07290015 Panel, Chassis, Front 1

38 95-07290041 Brace, Chassis, MVP/VHG 2

39 95-07290061 Cage Assembly, MVP 1

40 95-07290063 Base, Main, MPG/MPE 1

41 95-07290064 Axle, 26 Inch, MPG/MPE 2

42 95-07290065 Door, W/E - Box Opening, MPE 1

43 95-07290066 Bracket, E - Box & Chassis

Support 1

44 90-20231 Nut, Cage, 1/4" x 12 Ga. 20

45 90-2020 Nut, Cage, 3/8" x 12 Ga. 6

46 90-20040 Nut, 3/8", Flange Whiz Loc, NC 8

47 90-19961 Screw, 3/8" x 1-3/4" HH NC,

Whiz Loc 8

48 90-1996 Screw, 3/8" x 3/4" HH NC,

Whiz Loc 16

51 2-10942 Swivel, 1/2" NPT Hose Fitting 1

52 2-1105 Swivel, 1/2" JIC Fem. Push-on 2

53 90-20041 Collar, 5/8" Bore Shaft 3010 8

54 10-99079 Label, Platinum Series 2

55 90-19711 Screw 1/4" x 1/2" Whiz Loc 12

56 4-02110000 Hose, 1/2" Push-On /Ft. 2

57 90-10220 Bolt 3/8" x 3-1/2" 2

58 95-071211125 Pump Rail, Heavy Duty 1

59 95-0720085 Bracket, Wheel Brake 1

60 95-0720086 Assy, Lever Brake 1

61 2-01212 Cap, Vinyl, Yellow 1

62 90-1995 Screw, 1/4" x 1/2" 4

63 90-1992 Screw, 3/8" x 3/8" SKT 1

64 90-2001 Nut, 5/16" ESNA 1

65 90-200012 Nut, 1/4" Flame 4

66 90-4001 Washer, 5/16" Flat 3

67 6-0517 Strain, 3/4" (5-5C) 1

6-05171 Strain Relif, 1" (5-5B) 1

68 6-05182 Nut, 1" (5-5B) 1

69 2-01401 Bushing, Snap, 1-3/4" 1

▲ Not Shown