Landscape Forms Annapolis Bollard User manual

Other Landscape Forms Outdoor Light manuals

Landscape Forms

Landscape Forms Typology User manual

Landscape Forms

Landscape Forms Profile Area Light BW402 User manual

Landscape Forms

Landscape Forms Motive User manual

Landscape Forms

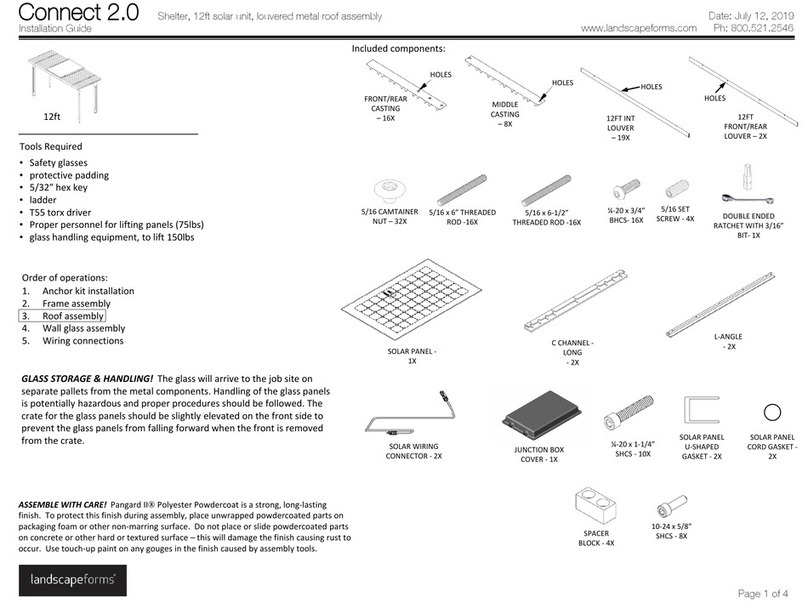

Landscape Forms Connect 2.0 User manual

Landscape Forms

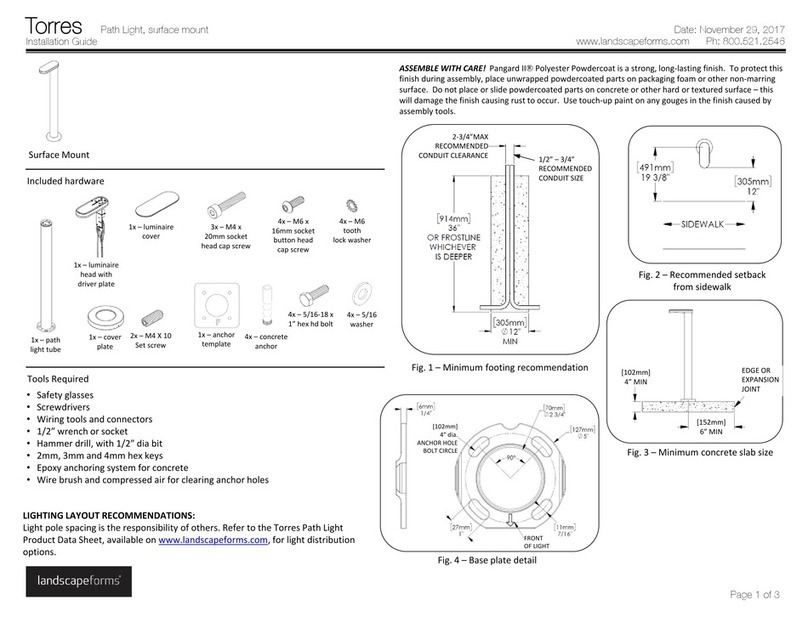

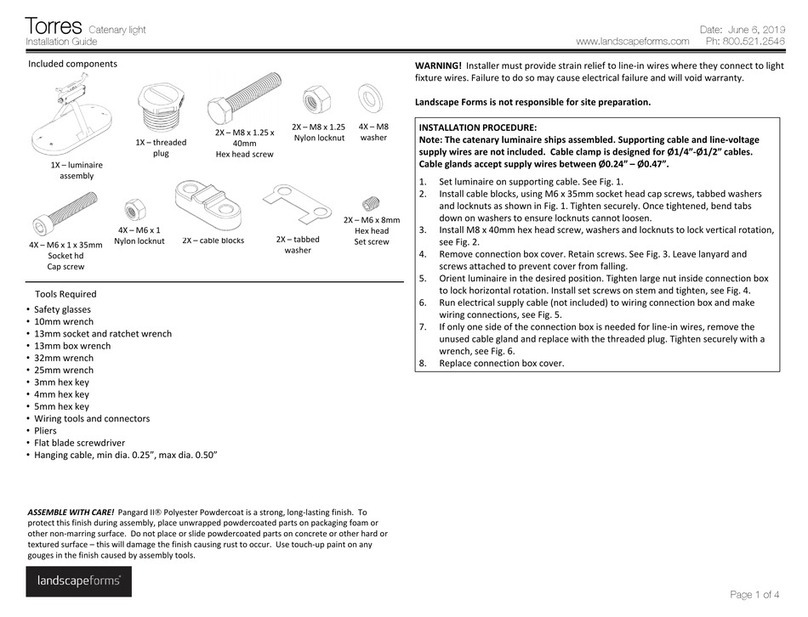

Landscape Forms Torres User manual

Landscape Forms

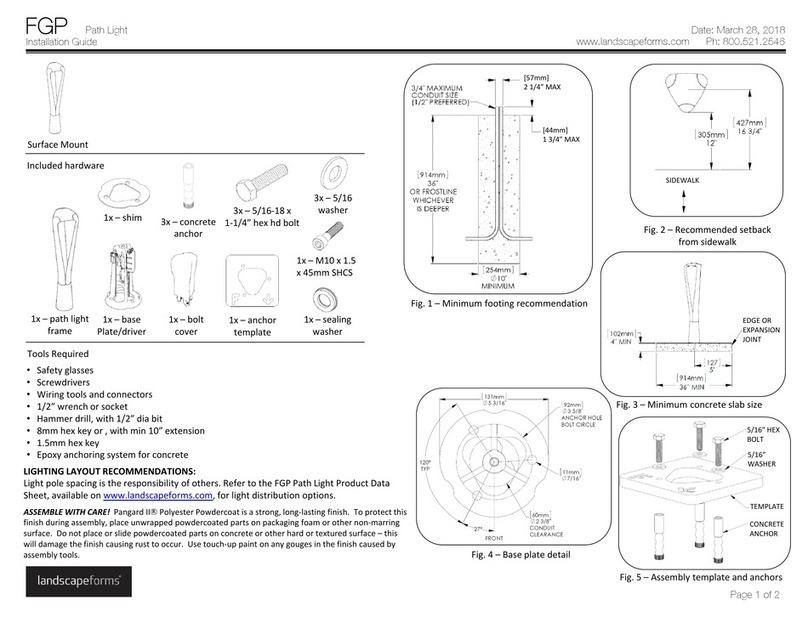

Landscape Forms FGP Path Light User manual

Landscape Forms

Landscape Forms Annapolis Bollard User manual

Landscape Forms

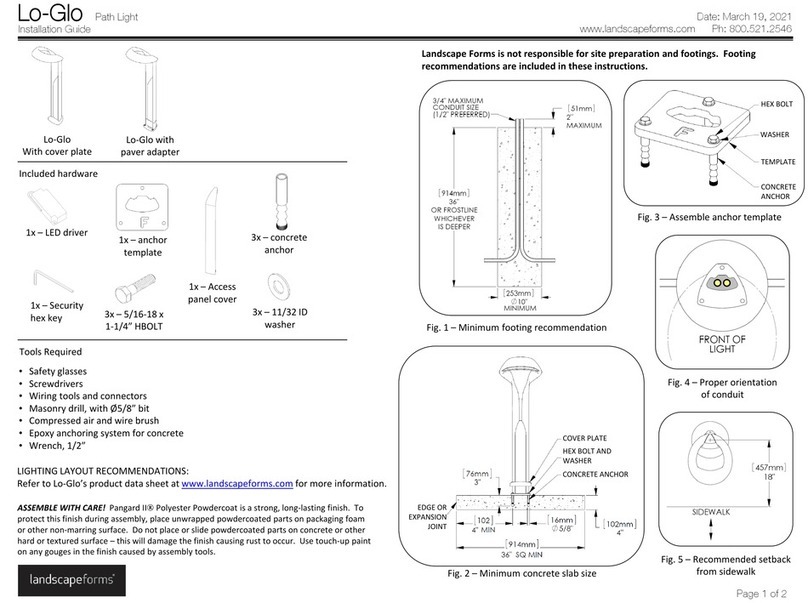

Landscape Forms Lo-Glo User manual

Landscape Forms

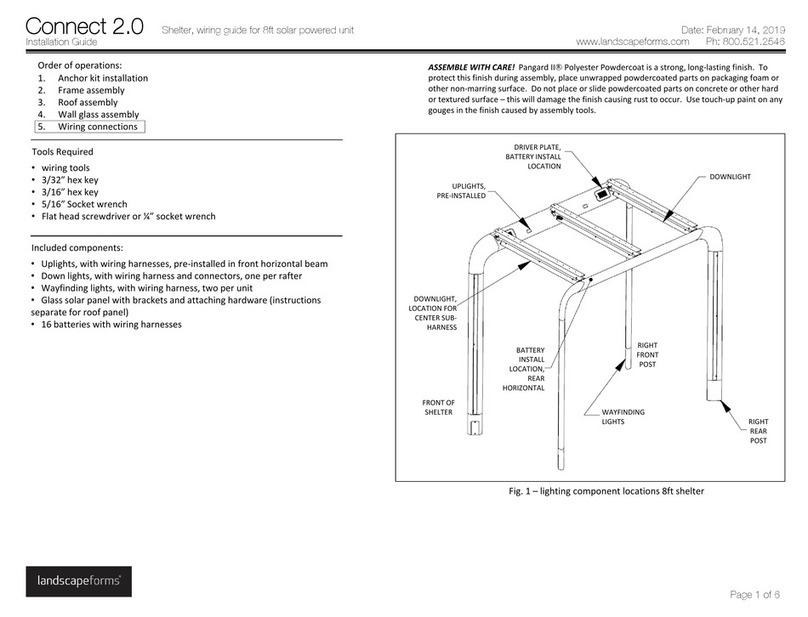

Landscape Forms Connect 2.0 User manual

Landscape Forms

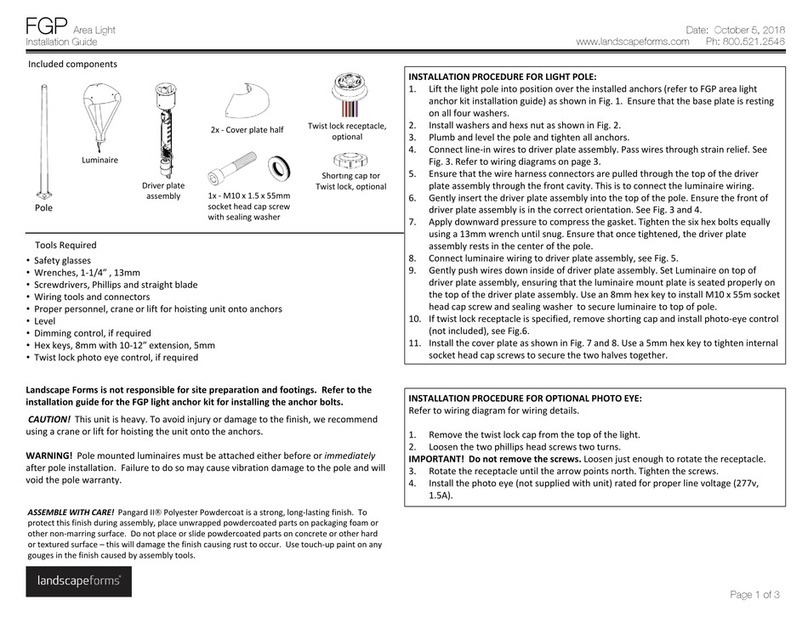

Landscape Forms FGP User manual

Landscape Forms

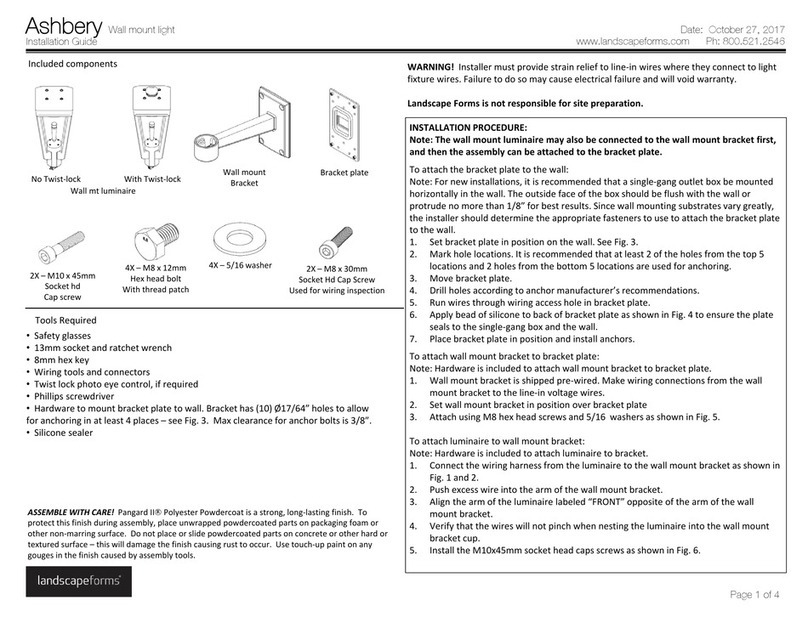

Landscape Forms Ashbery User manual

Landscape Forms

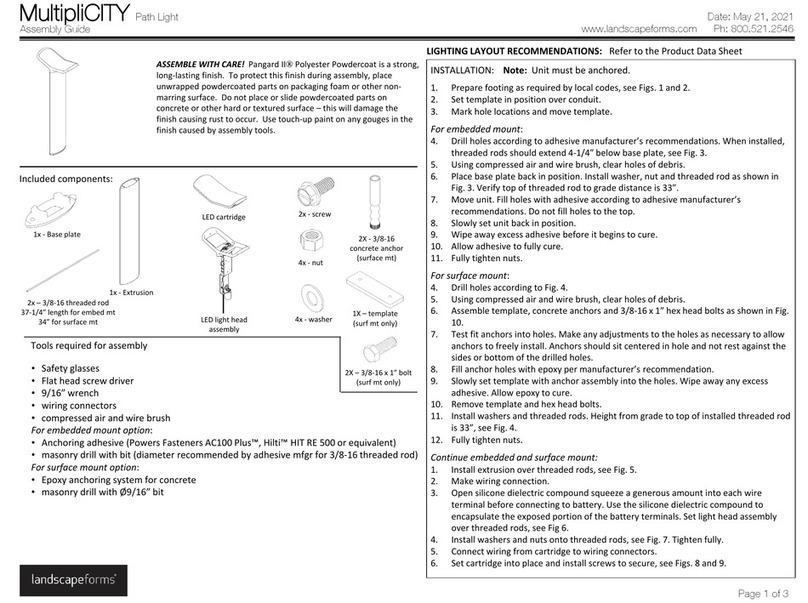

Landscape Forms MultipliCITY Path Light User manual

Landscape Forms

Landscape Forms Torres User manual

Landscape Forms

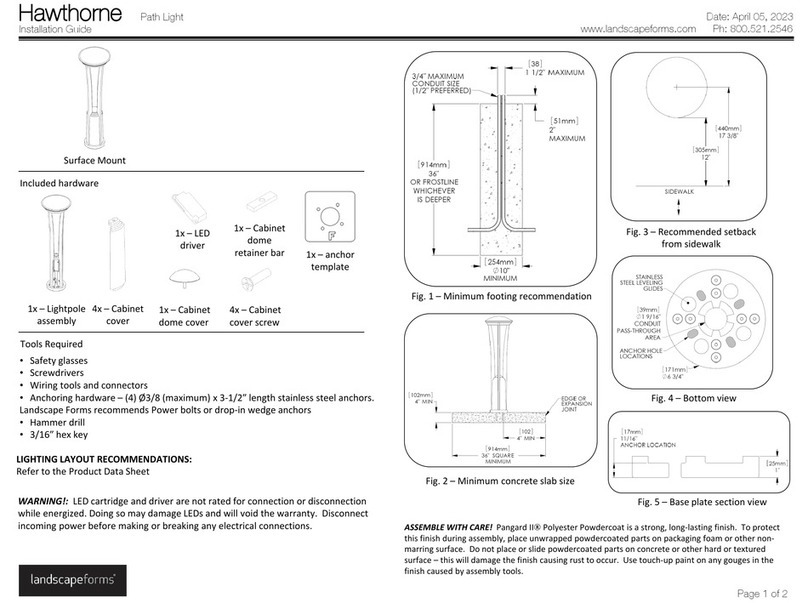

Landscape Forms Hawthorne User manual

Landscape Forms

Landscape Forms Ashbery User manual

Landscape Forms

Landscape Forms Signal User manual

Landscape Forms

Landscape Forms Profile BW103-2 User manual

Popular Outdoor Light manuals by other brands

HEPER

HEPER DOGO Side LW6048.585-US Installation & maintenance instructions

Maretti

Maretti VIBE S 14.6080.04.A quick start guide

BEGA

BEGA 84 253 Installation and technical information

HEPER

HEPER LW8034.003-US Installation & maintenance instructions

HEPER

HEPER MINIMO Installation & maintenance instructions

LIGMAN

LIGMAN BAMBOO 3 installation manual

Maretti

Maretti TUBE CUBE WALL 14.4998.04 quick start guide

Maxim Lighting

Maxim Lighting Carriage House VX 40428WGOB installation instructions

urban ambiance

urban ambiance UQL1273 installation instructions

TotalPond

TotalPond 52238 instruction manual

Donner & Blitzen

Donner & Blitzen 0-02661479-2 owner's manual

LIGMAN

LIGMAN DE-20023 installation manual