3

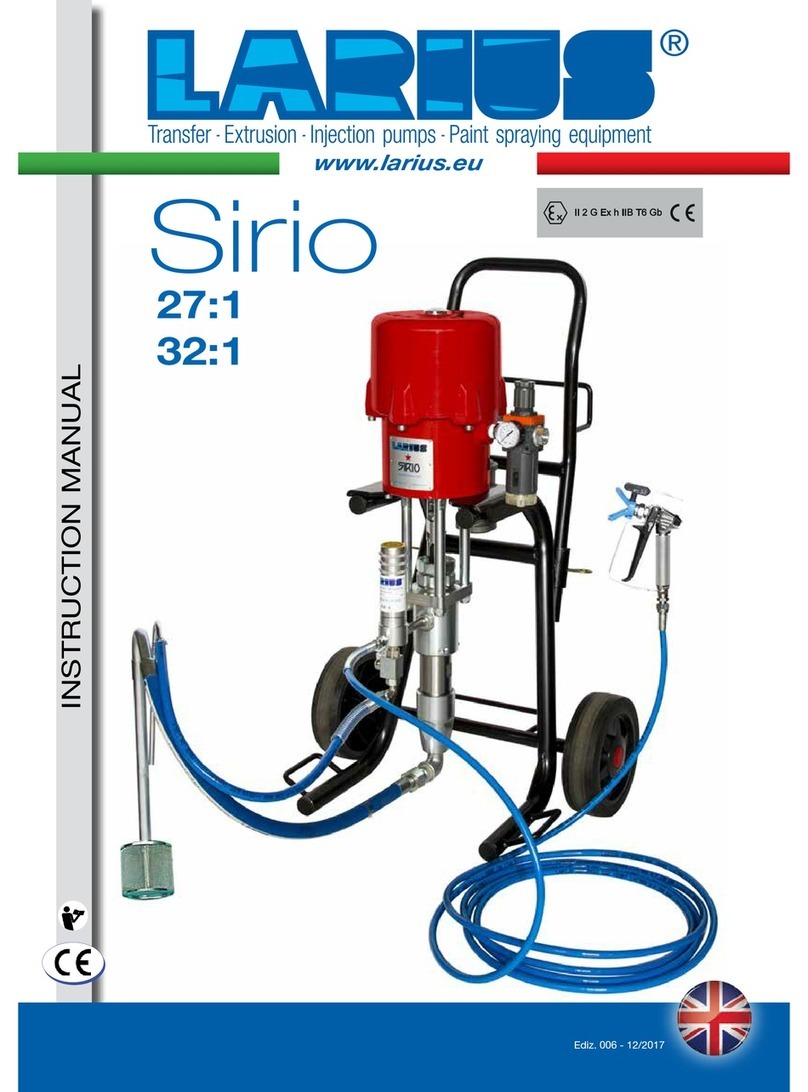

EXCALIBUR LINER

English

AWORKING PRINCIPLE

The LARIUS EXCALIBUR unit is defined “piston pump”.

An piston pump is used for high pressure painting without air (from

this process derives the term ”airless”).

The internal combustion engine, mounted upon the undercarriage,

powers the alternative piston pump.

A cam shaft and a connecting rod allow to obtain the reciprocating

motion necessary to the working of the “pumping group” piston.

The piston movement produces a “vacuum”.

The product is sucked, pushed towards the pump outlet and then

sent to the gun through the flexible hose.

A electronic device, allows to adjust and control the pressure of

the material coming out of the pump.

A safety valve avoiding overpressure, guarantees the total reliability

of the equipment.

The control zone allows for the possibility of:

• Activating the dispensing spray gun;

• Enabling or disabling the frontal steering wheel;

• Adjust the pressure of work;

This type of equipment is capable of painting one line at a time

in a single color.

The line can be either solid or dotted, based on the working

requirements.

SOLID LINE

1 2

BROKEN LINE

EXCALIBUR LINER is ideal for medium marking and mainte-

nance jobs.

Use water or non-refractive solvent filtered paint

specifically designed for airless application.

EXCALIBUR LINER allows for the marking and maintaining of all

types lines on highways, freeways, pedestrian crossings, parking

lots and squares, as well as every horizontal marking required

by the highway code.

Airless marking has numerous proven benefits with respect to

line-markers with pressurised tanks, which have been rendered

obsolete by airless-technology line markers.

Airless line-marking guarantees:

• Decreased Environmental Impact;

• Decreased drying time.

This line-marker utilises non-premixed paints. This allows it to

achieve about 30 % more yield with respect to standard line-

markers. Every model is also an airless spray gun which can be

used in the construction/decoration sector together with washable

products, enamels, breathable paints and flooring resins.

A vast assortment of accessories is available to satisfy every

customer demand.

The paint dries quickly and the line is defined in a uniform manner

with a single coat. The airless function requires the use of filtered

paint which is specifically designed for airless application. This

means that the paint is homogeneous, of a smooth and uniform

consistency and will not form crusts, nor will it become gelatinous

or thick. With this airless line-marker, the paint adheres firmly to

all types of pavement, with optimal visibility, and is resistance to

wear caused both by traffic as well as atmospheric agents.

In the LARIUS models, the paint canister can be loaded directly

upon the undercarriage or else poured into the non-stick, 50 L

tank. In every case, cleaning, maintenance and colour change

operations are facilitated.

The line-marker is equipped with pivoting frontal wheel which even

increases the agility of the larger models.

High yield, high efficiency, high versatility.