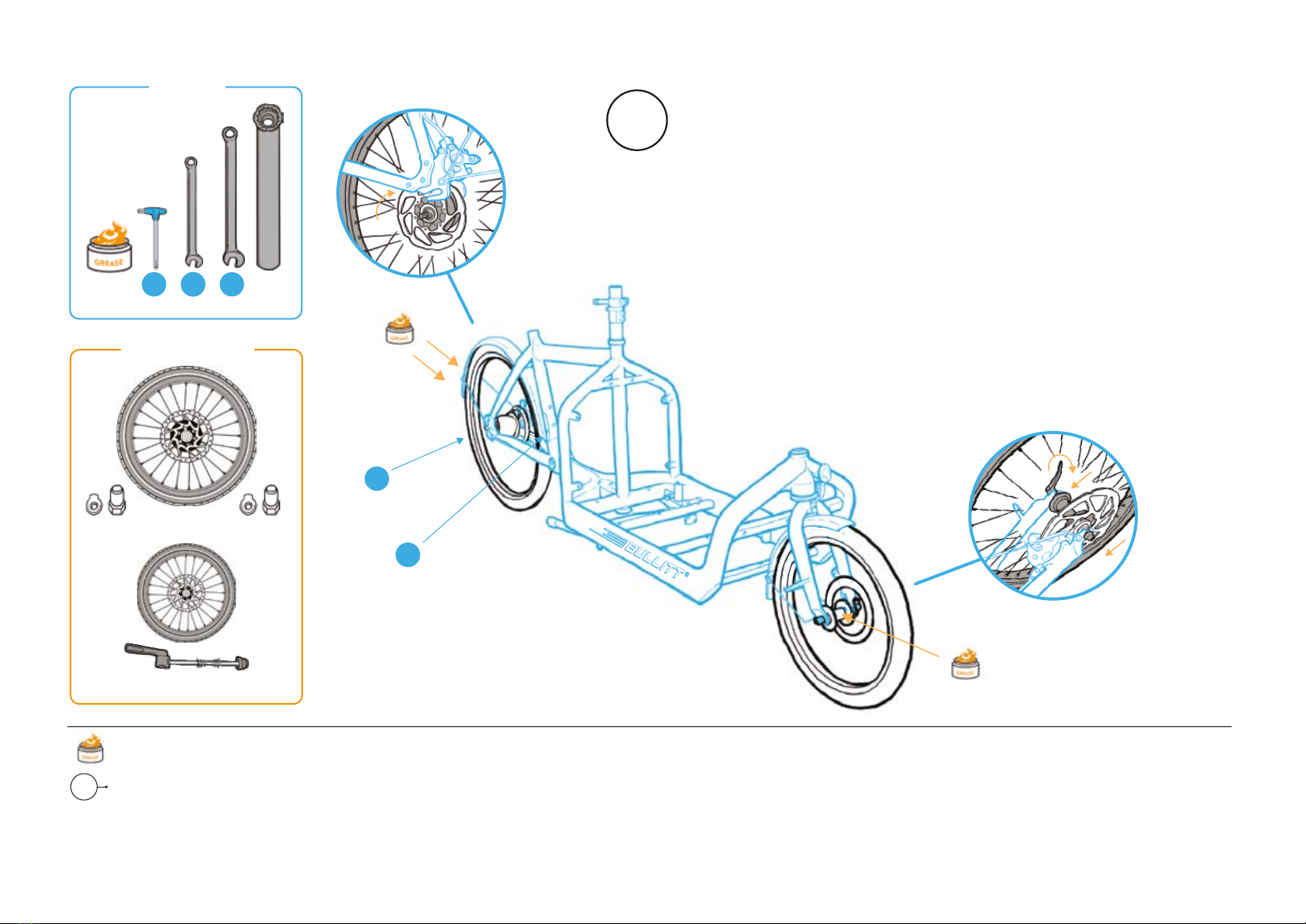

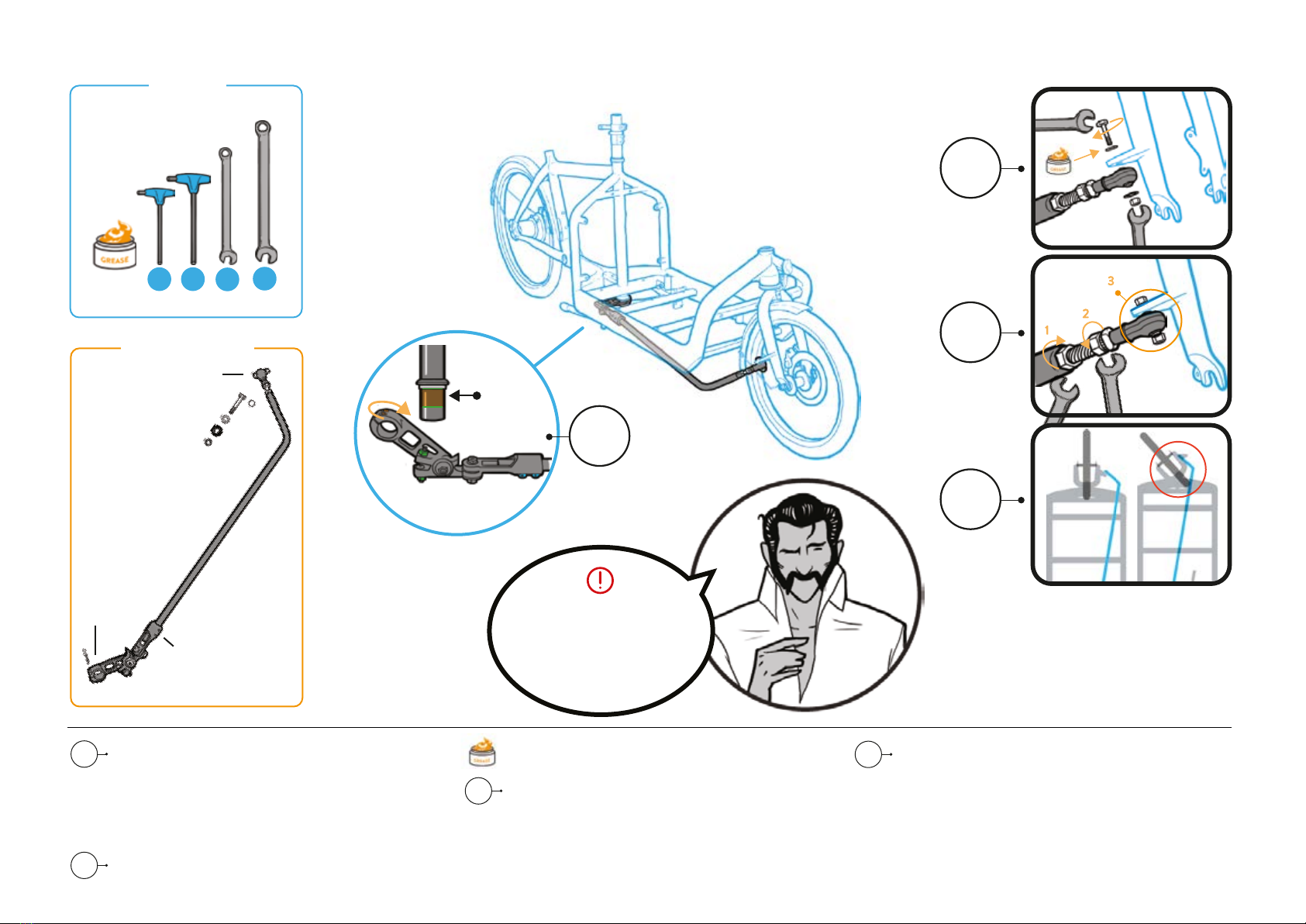

Step 6 Mount Steering Arm

17

mm

13

mm

x2

x2

Steering Arm

Clamp on

in this area

45

mmmm

Steering

rod clamp

Length and angle

adjustment clamp

Ball joint

Attach clamp at the end of steering arm to the steering

rod, by sliding the clamp all the way up until it touches

the underside of the crown race. Lightly tighten bolts.

(FIG. A) (Later tighten completely to adjust the alignment

between handlebar and front wheel).

Torque the clamp to the steering rod 2x 5mm (7-9Nm).

Bolt the ball joint underneath the fork tab (11-14Nm).

Grease the bolt and make sure the washers and

shims are in the correct order.

Tighten the 17mm nuts at the ball joint, starting with the

rear one (6.2.1),repeat for the front (15-18 Nm) or until

star washers are locked (6.2.2)

Align ball joint to fork tab, so it moves smoothly through

the steering cycle (without unlocking star washers) (6.2.3)

Adjust Steering Rod length and angle at the clamp with 2x

4mm hex bolts (so the tire doesn’t rub arm or oversteer

when handlebar is turned all the way left or right)

Tighten bolts (5Nm). Adjust alignment between

handlebar and front wheel so the bike rides straight.

Fully torque the steering arm clamp to the steering rod

2x 5mm hex bolts (7-9Nm).

Be patient and check that the

steering arm doesn’t contact the corner

of the frame (2cm gap) or kickstand,

when it is up also.

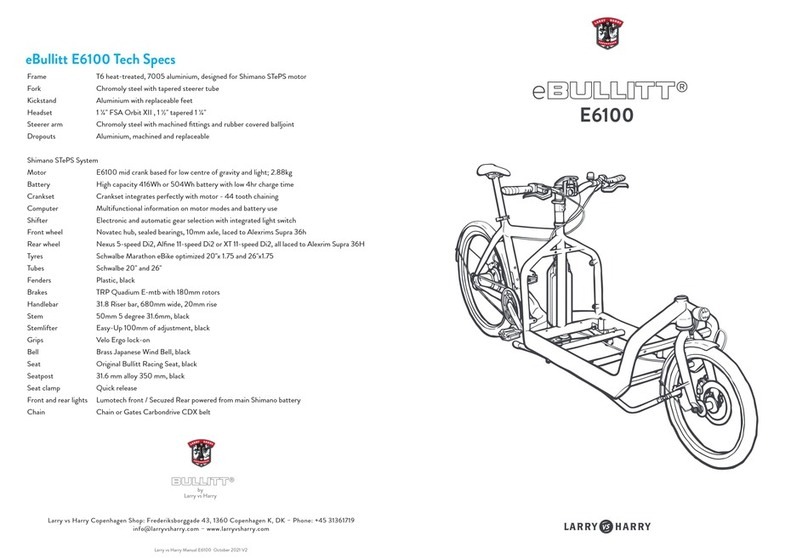

Components

Tools

6.0

6.1

6.2

6.3

6.0

6.1

6.2

6.3

ALIGN

1

2

3