ICS Contactors Wiring Manual

01518-53-000 Page 4 of 8 Issue 2 13 January 2020

2 Concept

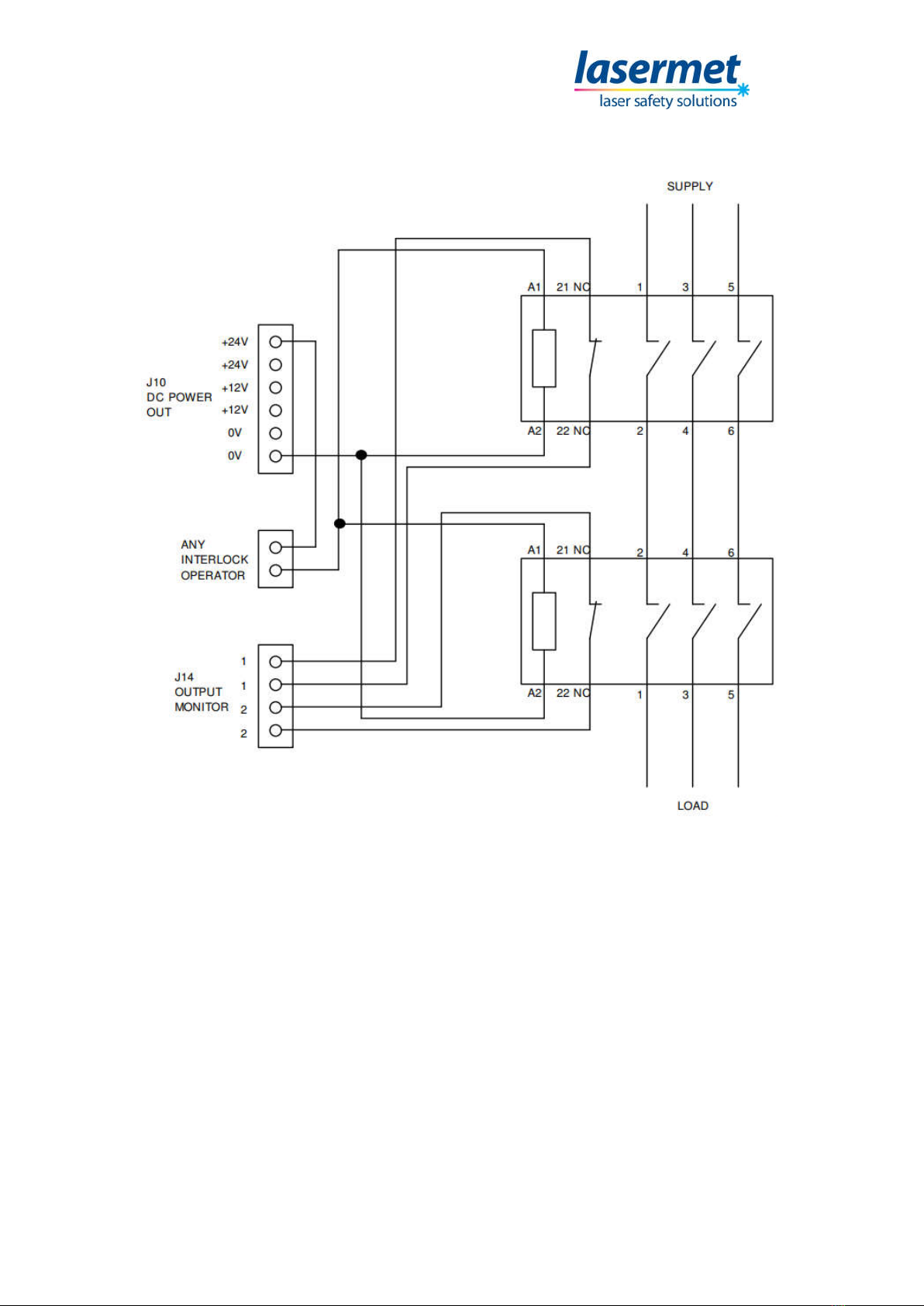

When it is necessary for a Lasermet ICS-5 or ICS-6 Interlock Control Panel to switch the mains power

to a laser or other controlled equipment the internal contacts of the ICS may not be sufficiently

rated to switch high powers. In these situations, Lasermet offer a power contactor box.

The contactors are wired so that the supply is turned on when the ‘Arm Laser’ button is pressed and

the system arms and turned off when the system is disarmed e.g. by opening a door or setting the

ICS keyswitch to ‘Disable’.

In general, Lasermet supply either 18A or 32A four-pole contactors. The ratings for each type are as

follows:

18A type AC-3 Rating 18A AC-1 Rating 32A

230V 4kW

400V 7.5kW

690V 10kW

32A type AC-3 Rating 32A AC-1 Rating 50A

230V 7.5kW

400V 15kW

690V 18.5kW

The box contains two contactors whose line contacts are pre-wired in series such that the power to

the load is cut if either or both contactors open. The ICS monitors both contactors and if one of them

fails to open when the system is disarmed, the ICS cannot be re-armed. This provides protection

against the ‘dangerous’ failure of a single contactor.

The contactor box needs to be wired to the line and load cables to be switched, and the box may

conveniently be located near these.

All wiring to the contactor main terminals must be made using wire of current and voltage rating

appropriate to the power to be carried.

Overcurrent protection devices must be provided on the supply side of the main contacts to protect

the load, contactors and wiring against excessive current under fault conditions.

The contactors are provided with four-line contacts. For a single-phase installation, use two of the

contacts only to switch live and neutral. For three-phase installation, use three contacts for the three

phase lines and the fourth for the neutral.

NOTE: Ensure that earth continuity is maintained at all times between line and load cables using

separate earth terminals. The earth must not be switched through the contactors.

It is then necessary to run either one 6-core or two 4-core cables between the ICS-5 / ICS-6 and the

contactor box. These cables will carry low current 24V control signals, and cables with 7/0.2mm

stranded copper cores are ideal. Lasermet can supply suitable miniature double-insulated cable with

a 250V insulation rating, which allows the cables to be run in proximity to 110V/240V mains cables if

needed.