4User manual CM 1200 BB

INTRODUCTION

The purpose of this manual is to furnish the

owner and operator with a set of practical, safe

instructions on the use and maintenance of the

CM 1200 BB tyre changer.

Follow all the instructions carefully and the ma-

chine will give you the efficient and long-lasting

service that has always characterised CORMACH

products, making your work considerably easier.

The following points define the levels of danger

regarding the machine, associated with the war-

ning captions found in this manual:

DANGER

Refers to immediate danger with the risk of

serious injury or even death.

WARNING

Dangers or unsafe procedures that can cause

serious injury or even death.

CAUTION

Dangers or unsafe procedures that can cause

minor injuries or damage to property.

Read these instructions carefully before powe-

ring up the machine. Keep this manual and all

illustrative material supplied with the machine

in a folder near the tyre changer, where it is rea-

dily accessible for consultation by the machine

operators.

The technical documentation supplied is consi-

dered an integral part of the machine and must

always accompany the equipment if it is sold or

transferred to a new owner.

The manual is only to be considered valid for the

machine model and serial number indicated on

the nameplate applied to it.

WARNING

Observe the contents of this manual: the ma-

nufacturer declines all liability in the case of

uses of the machine not specifically described

and authorised in this manual.

WARNING

This machine must be used only by qualified

and authorised personnel able to understand

the written instructions provided by the manu-

facturer of the machine, the tyres and the rims.

He must be suitably trainedand conversant with

the safety procedures. Use of the machine by

unskilled staff may con

stitute a serious risk for the operator and for

the final user of the product processed (the

wheel rim and tyre mounting).

NB:

Someofthe illustrationsin thismanualhavebeen

taken from photographs of prototypes: standard

productionmachines may vary in some respects.

These instructions are intended for people with

basic mechanical skills. We have therefore omit-

ted detailed descriptions of procedures such as

how to loosen or tighten the fixing devices on the

machine. Do not attempt to perform operations

unless properly qualified and with suitable ex-

perience. In case of need, contact an authorised

Service Centre for assistance.

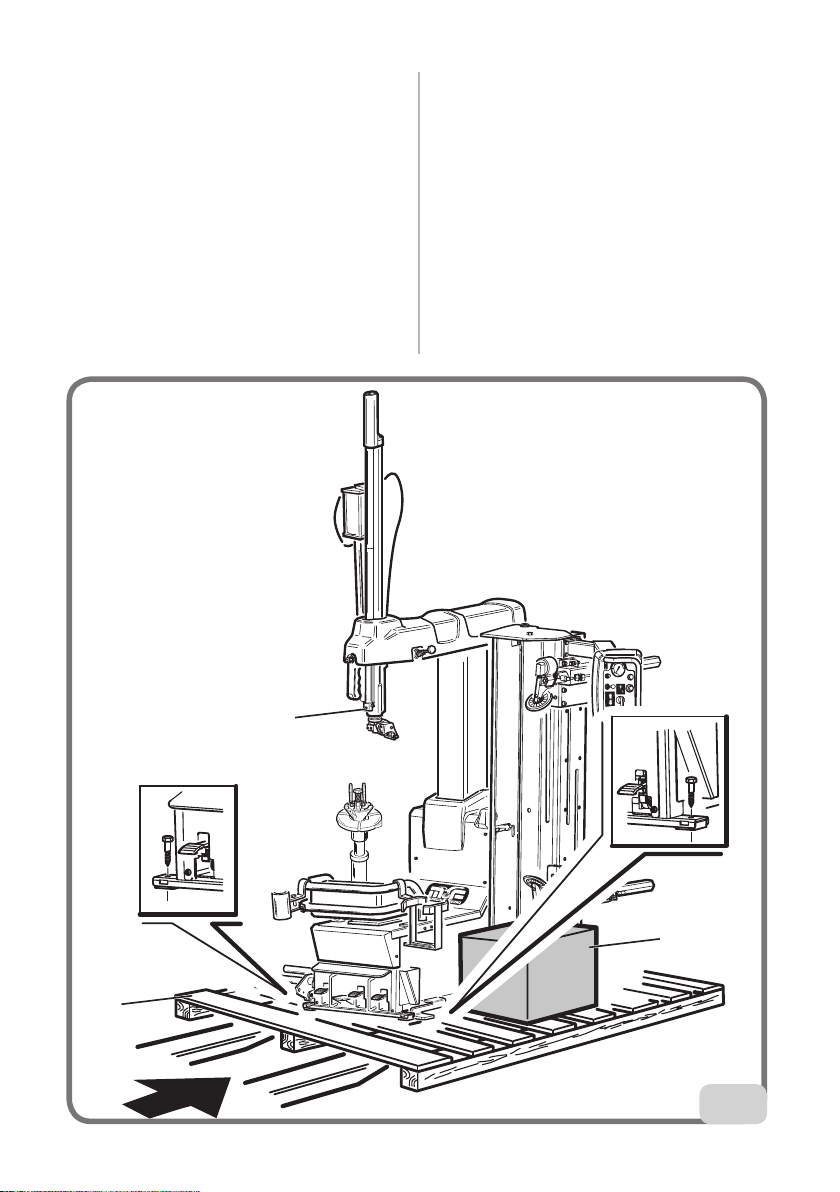

TRANSPORT, STORAGE AND

HANDLING

Conditions for transporting the

machine

The tyre changer must be transported in its

original packaging and stowed in the position

shown on the packaging itself.

- Packaging dimensions:

• width ...................................................1543mm

• depth ..................................................1140mm

• height ..................................................1900mm

- Weight of wooden packaging:

• .................................................................. 380kg

Ambient conditions for machine

transport and storage

Temperature: -25° - +55°C.

WARNING

Do not stack other goods on top of the packa-

ging, to avoid damaging it.

Handling

To move the packaging, insert the tines of a