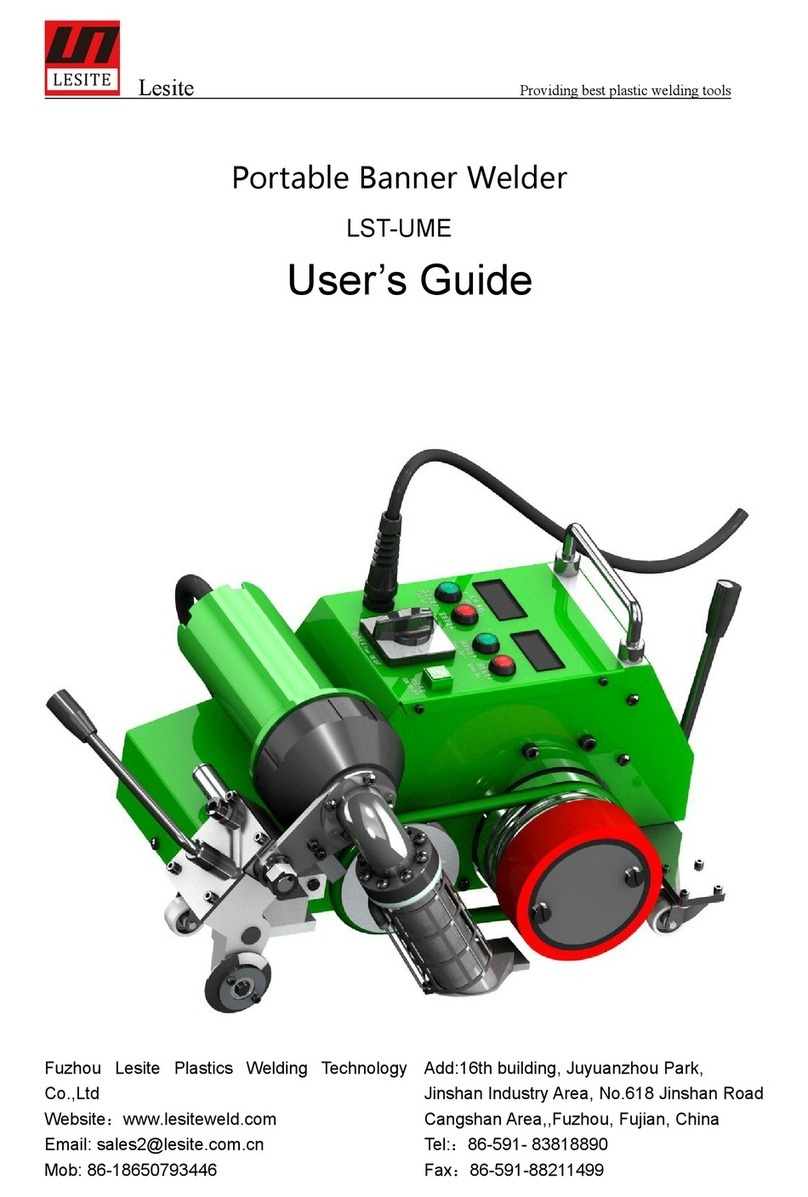

Lesite Providing best plastic welding tools

Fuzhou Lesite Plastics Welding Technology Co.,Ltd

Website:www.lesite.com.cn

www.lesiteweld.com

Email: sales2@lesite.com.cn

Mob: 86-18650793446

Add:16th building, Juyuanzhou Park,

Jinshan Industry Area,

No.618 Jinshan Road

Fuzhou, Fujian, China

Tel: 86-591-83818890

Fax: 86-591-88211499

1. Company

Fuzhou Lesite Plastic Welding Technology Co., Ltd. is a professional high-tech

enterprise engaged in the development and sales of electromechanical

integration. "Realistic and pragmatic, sincere humility, excellence, strive for

perfection" is adhered to by all employees of the company. Pursuing efforts to

provide users with advanced technology, quality products, and good service is

our consistent purpose. The company has advanced production and test

equipment, and often make technical training for workers to ensure the

advanced technology and equipment, to create good conditions for producing

high-quality and cost-effective products. With a perfect quality assurance

system, from procurement of raw materials, production processes, factory

inspection to ensure that the products can be 100% qualified out of factory.

.

We always follow the quality first, user supreme principle. With the best

products into the market, and return the user with the best service, the

company will continue to carry out technical innovation, improve production

processes, improve product quality, and strengthen after-sales service for the

user to eliminate the worries. User's needs are our pursuit. We are sincerely

looking forward to working with you and creating brilliant future..

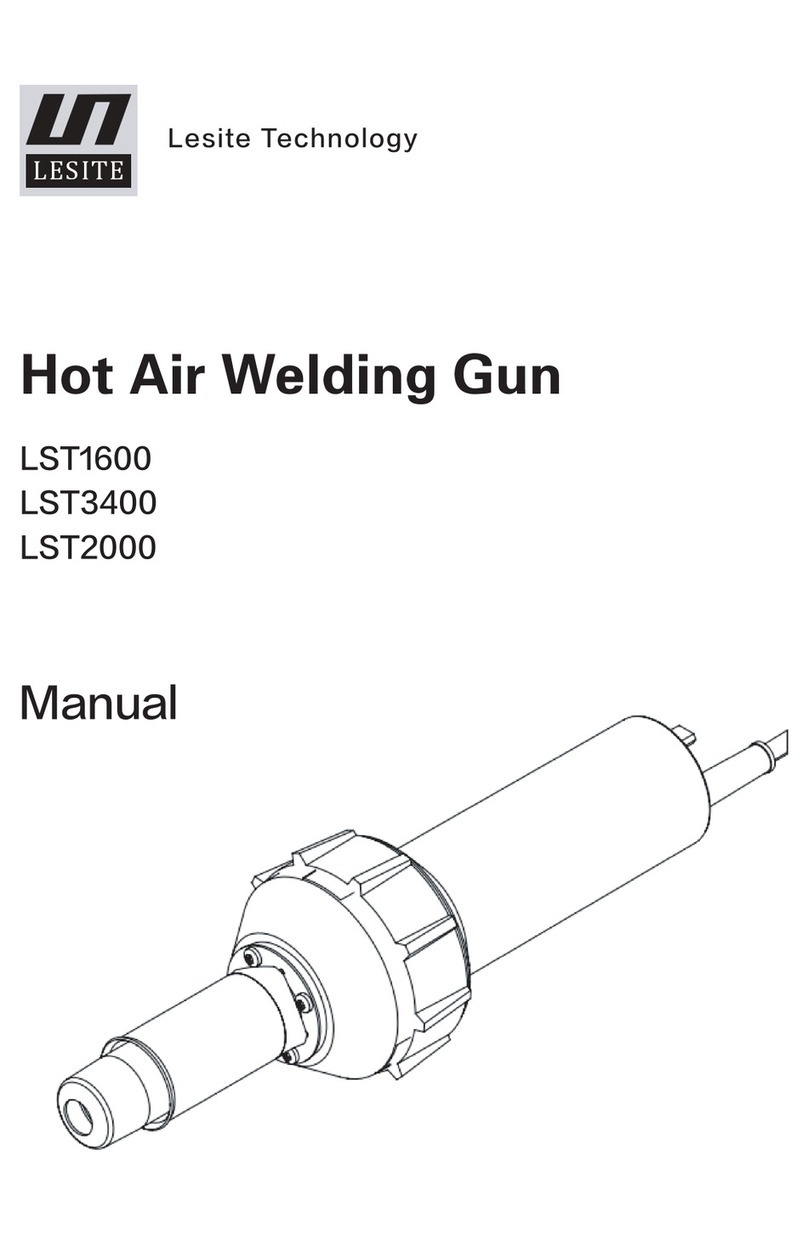

Lesite series geomembrane welding machine, plastic welding machine is

jointly developed by Fuzhou Lesite Plastic Welding Technology Co., Ltd. and

Research institutes. These new generations of geomembrane welding, plastic

welding equipment meet the needs for plastics industry continuously

expanding the application in the modern social engineering. With an advanced

hot-wedge, hot air structure to weld plastic for a variety of different material

and thickness. It is available for welding of HDPE, PVDF, EVA, PP, etc. all can

be hot-melt material. Part of this series welding temperature control use

automatic stable PID control for high precision, small fluctuations in

temperature and speed control partly using the pulse width modulation (PWM)

steady voltage and steady speed circuit, the DC servo motor drive, big output

torque and a smooth walking, in climbing, vertical creeping and road load

changes to keep the speed constant. This series of welding machines have

stable performance, convenient operation, high welding efficiency, reliability,