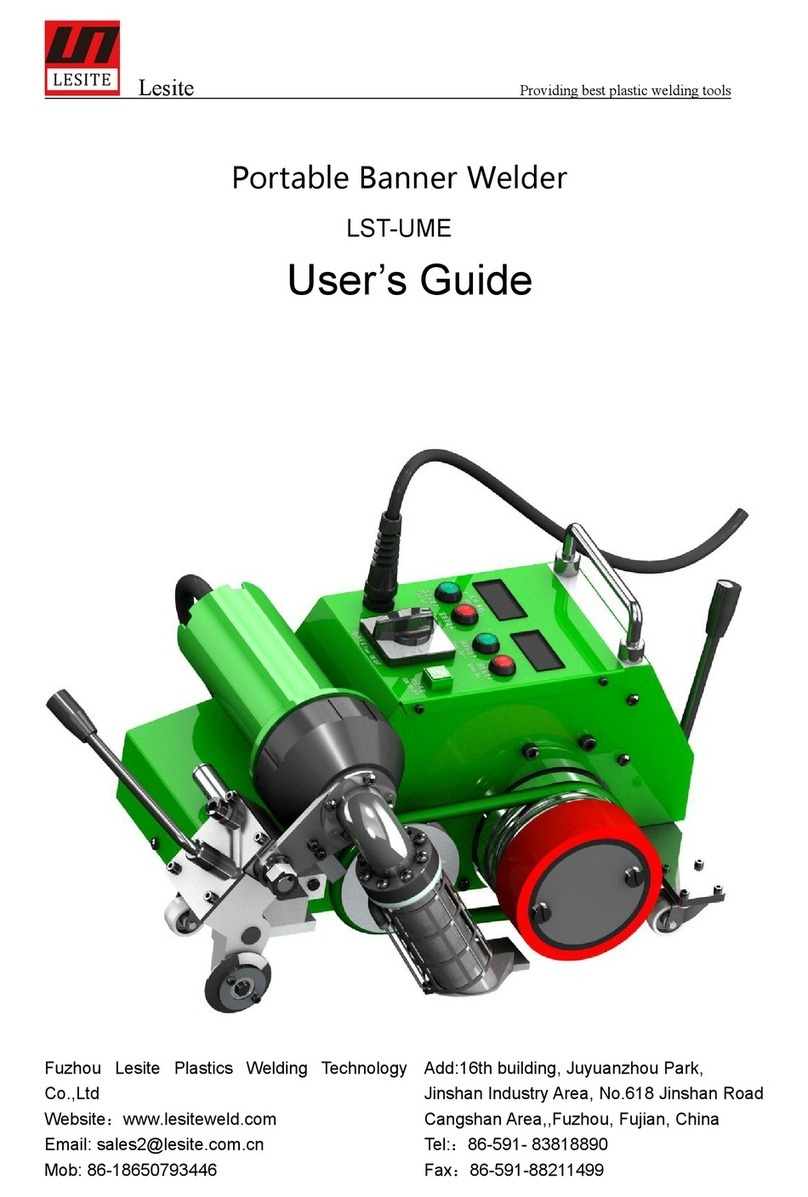

Lesite Providing best plastic welding tools

Fuzhou Lesite Plastics Welding Technology Co.,Ltd

Website:www.lesiteweld.com

Mob: 86-18650793446

Add:16th building, Juyuanzhou Park,

Jinshan Industry Area, No.618 Jinshan Road

Cangshan Area,

Fuzhou, Fujian, China

Tel::86-591- 83818890

Fax:86-591-88211499

Please read this manual carefully before using this machine, and retain it for future reference.

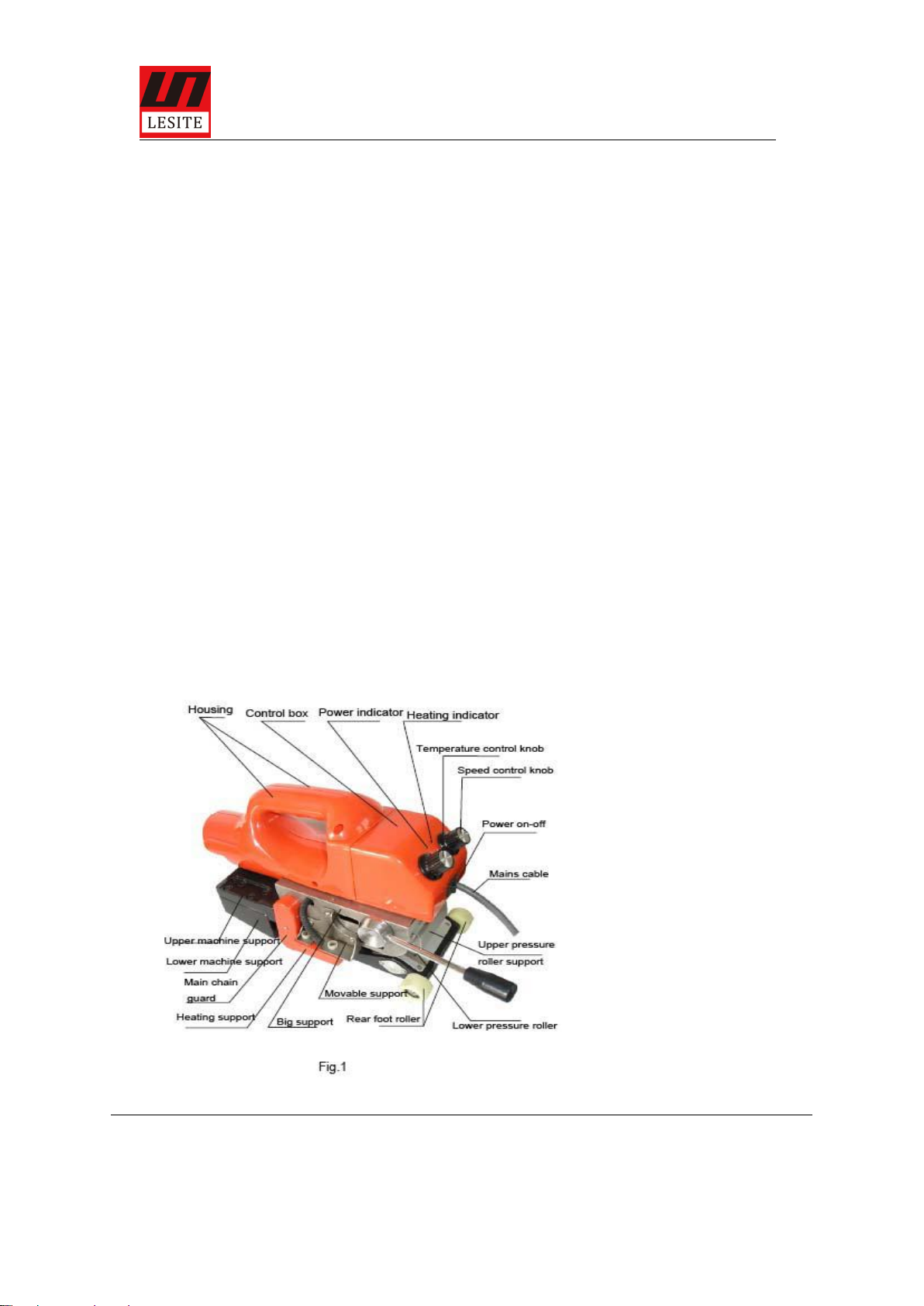

LST800/800D geo-membrane welding machine is our new developed products, which can weld

geo-membrane of various thicknesses and are applicable for welding of all thermal-fused material such

as LDPE, PVC, HDPE, EVA, and PP and so on.

The control of this series of welding machine adopts PID automatic thermostatic control with high

control accuracy and low temperature fluctuation; speed control adopts PWM automatic voltage and

speed regulation circuit, driven by DC servo motor, with great output torque and the operating is stable. It

can maintain a constant speed on the condition of creeping, vertical creeping and variable road load.

Also this series of welding machine is stable in performance despite of external temperature and voltage

variation.

This series of welding machine is excellent in performance and easy for operating, with high welding

speed and good work quality. It is extensively used in engineering projects such as expressways, tunnels,

reservoirs, waterproof of construction and so on

1. Technical parameters

Voltage (V): 220V or 110V

Frequency (Hz): 50Hz

Power (P): 800W

Welding speed (V): 0.8-6m/min

Heating temperature (T): 0-450℃

Thickness of material to be welded: 0.2mm-1.5mm

Overlap width: 100mm (or 120, 150, 200mm)

Welding width: 12.5mm×2, interior cavity 12mm

Seam strength: ≥85% base material (tensile resistant in shear direction), complete machine

Dimensions: L32 x W15cm xH22cm

Net Weight: 4.8kg, Gross Weight: 8.5kg

Insulation class: class II