Before starting check with the AutoAnchor manufacturer, or supplier, that it is

possible to t the sensor and magnet to your horizontal windlass.

For an accurate rope count the rode must run between the sensor and magnet. On a

horizontal windlass the magnet and sensor must be tted by the windlass manufacturer.

If it is not possible to have the sensor and magnet tted to achieve this you can use the

chain only horizontal windlass installation above. This provides an accurate count of

rode deployed but during retrieval the display may be incorrect because it cannot

allow for the stretch in the rope.

2.1.9 INSTALLATION HORIZONTAL WINDLASS - ROPE & CHAIN

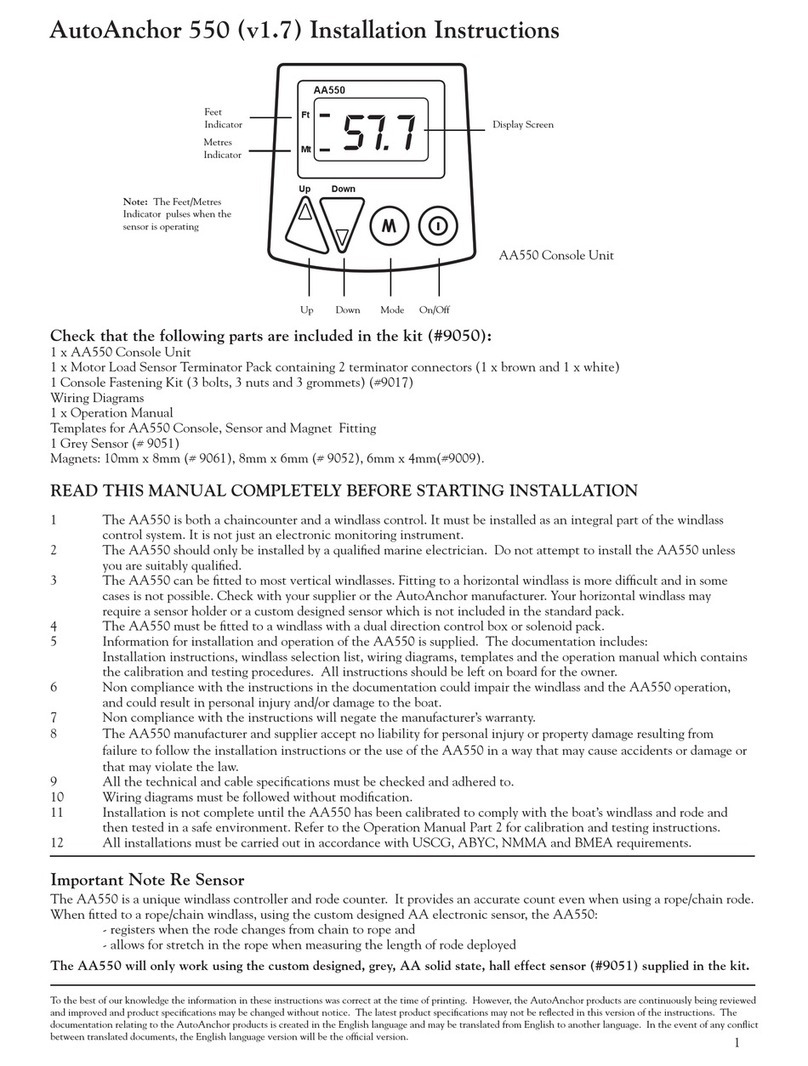

Gap Between the Sensor and Magnet:

Minimum 5mm and maximum 40mm.

The magnet and sensor must be tted so that the gap remains consistent as the

winch turns.

Magnet Installation:

Size: 10mm x 8mm magnet (#9061).

The magnet can be mounted on the main shaft or on the side of the drum. See Figs 8 and

9. If mounted on the side of the drum, position it close to the inside to reduce the

peripheral speed of the magnet. Fix the magnet into position with epoxy ensuring it is

completely sealed to prevent corrosion.

Sensor Installation

The Grey 3 wire AutoAnchor sensor (#9067) is recommended but a proximity sensor may

be used. Every installation is different so this manual can provide guidelines only. The AA

sensor holder #9070, or a customised sensor holder, will be required to ensure the

sensor remains in position and the gap is consistent between the sensor and magnet

during operation.

2.1.10 INSTALLATION DRUM WINCHES

Sensor Connection: The AutoAnchor plug and play sensor extension cable must be

used to connect the sensor to the console unit. Ensure the connectors are rmly screwed

together. See the information on page 4.

Loose cable should be tied in place with cable ties and kept clear of chain.

2.2 CONSOLE INSTALLATION

Choose a position where the operator will be able to see the anchor and windlass when

using the AA560.

Mount on a at surface at least 3ft (1m) away from any equipment or cables carrying

radio signals eg VHF radios, cables and antennas or radar antenna and at least 6ft (2m)

away from any SSB equipment. The front of the console is waterproof but the cable boot

on the back is designed to breathe. Mount the console so that the back is protected from

moisture. Refer to the drilling template to drill the 4 holes to mount the console. Do not

use sealer or glue. The rubber grommets will seal the unit. Do not use metal studs, nylon

bolts are supplied. These should be hand tightened only.

2.2.1 MULTIPLE CONSOLE INSTALLATION

Up to 3 AA560 consoles can be installed to provide multiple control stations. The AA560

can also be installed with other windlass control stations eg foot switches, remote controls

and other AutoAnchor products. T-adapters and 2m extension cables are available for

multiple installations. Refer to the wiring diagrams and pages 4 and 5 for details. If you

are uncertain how to proceed contact your supplier.

Multiple battery bank negative terminals must be permanently connected together to

become the common negative return (ground).

Power supply to the AA560 must be from the windlass control circuit, along with all other

windlass controls eg. toggle switch, remote switches, deck switches, other AutoAnchor

devices. Power supply must not be from the motor positive near the windlass.

12V or 24V DC power supply is required.

Check battery polarity before connecting power.

Refer to the windlass manufacturer’s specications for fuse/breaker, isolator and main

power cable specications. Ensure any fuse/breaker on the control circuit has a rating

applicable to the current loads connected to the outputs. (AA560 Output maximum is 4

Amps). An additional isolating switch should be installed for controls if the main breaker or

isolator is not readily acessible from the helm.

THE POWER SUPPLY MUST BE DISCONNECTED WHEN INSTALLING,

CONNECTING OR CHANGING THE WIRING

2.3 POWER SUPPLY

910

For drum winch set up and operation, refer to page 19.

Magnet

on side of

drum

Magnet

on shaft

Sensor

Sensor

Fig 8 Fig 9

Magnet

Sensor

Fig 7

OD

ID