2

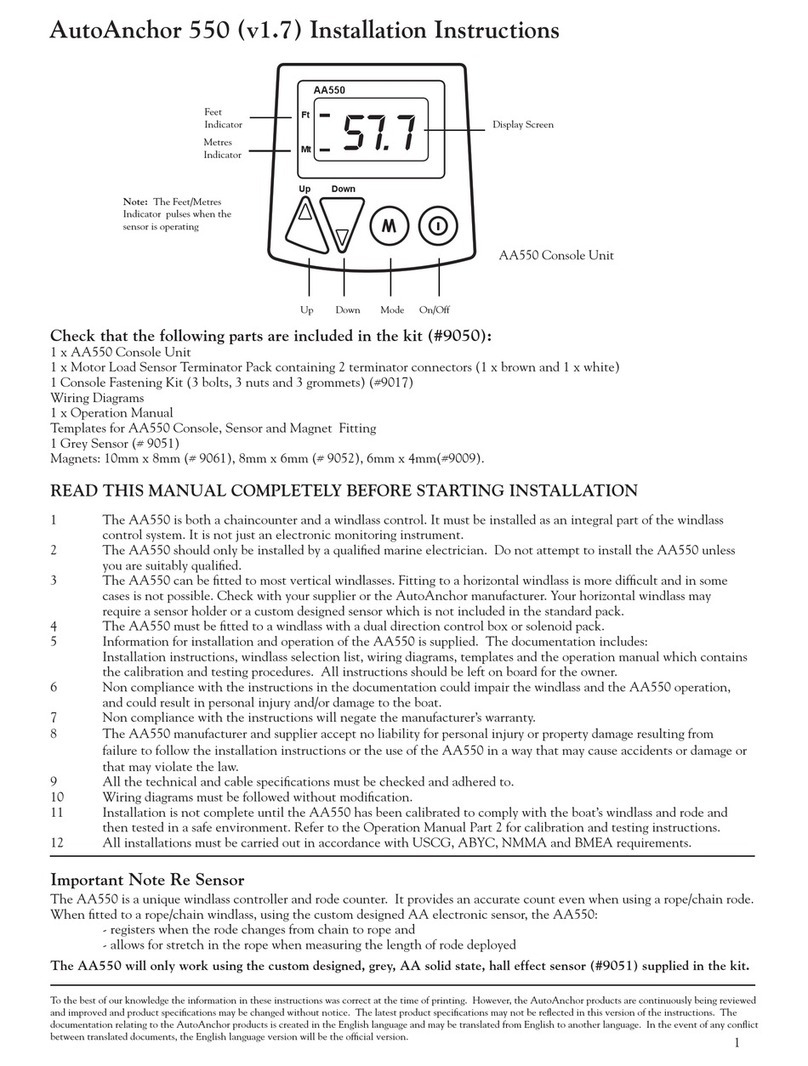

IMPORTANT: Read these notes before continuing.

!Responsibility for the safe and prudent operation of a vessel rests with the owner and/or operator of the

vessel. The Integra drive is one of many devices to aid in the general operation of a vessel, it does not relieve

the operator from the responsibility of safety or maritime procedures of the vessel.

!Avoid navigational hazards and never leave the helm unattended.

!Always be prepared to immediately regain manual control of the vessel.

!Learn to operate the autopilot in calm open water with minimum hazards.

!Use caution when the vessel is at high speeds near hazards in the water, such as pilings, docks and other

vessels.

!Keep up to date with any product safety information published at Lewmar.com

!This equipment must be installed and operated in accordance with the instructions contained in this manual.

Failure to do so could result in poor product performance, personal injury and/or damage to your boat.

!Always wear safety goggles, ear protection and a dust mask when using power tools. When drilling or cutting

check the opposite side of the surface. Be aware of fuel tanks, electrical cables, hydraulic hoses etc.

!Consult the boat manufacturer if you have any doubt about the strength or suitability of the mounting

location.

!Make sure you have switched off the power before you start installing this product.

!If in doubt about installing electrical equipment please seek advice from a suitably qualified electrical

engineer.

EMC Recommended guidelines

All Lewmar equipment and accessories are designed to conform to the appropriate Electromagnetic Compat-

ibility (EMC) standards. Correct installation is required to ensure that performance is not compromised. The

guidelines given here describe the conditions for optimum EMC performance, but it is recognised that it may

not be possible to meet all of these conditions in all situations. To ensure the best possible conditions for EMC

performance within the constraints imposed by any location, always ensure the maximum separation possible

between different items of electrical equipment. For optimum EMC performance, it is recommended that wher-

ever possible Lewmar equipment and cables connected to it are:

!At least 3ft (1m) from any equipment transmitting or cables carrying radio signals e.g. VHF radios, cables and

antennas.

!In the case of SSB radios, the distance should be increased to 7ft (2m).

#WARNING!

2- Safety Notice

1- Introduction

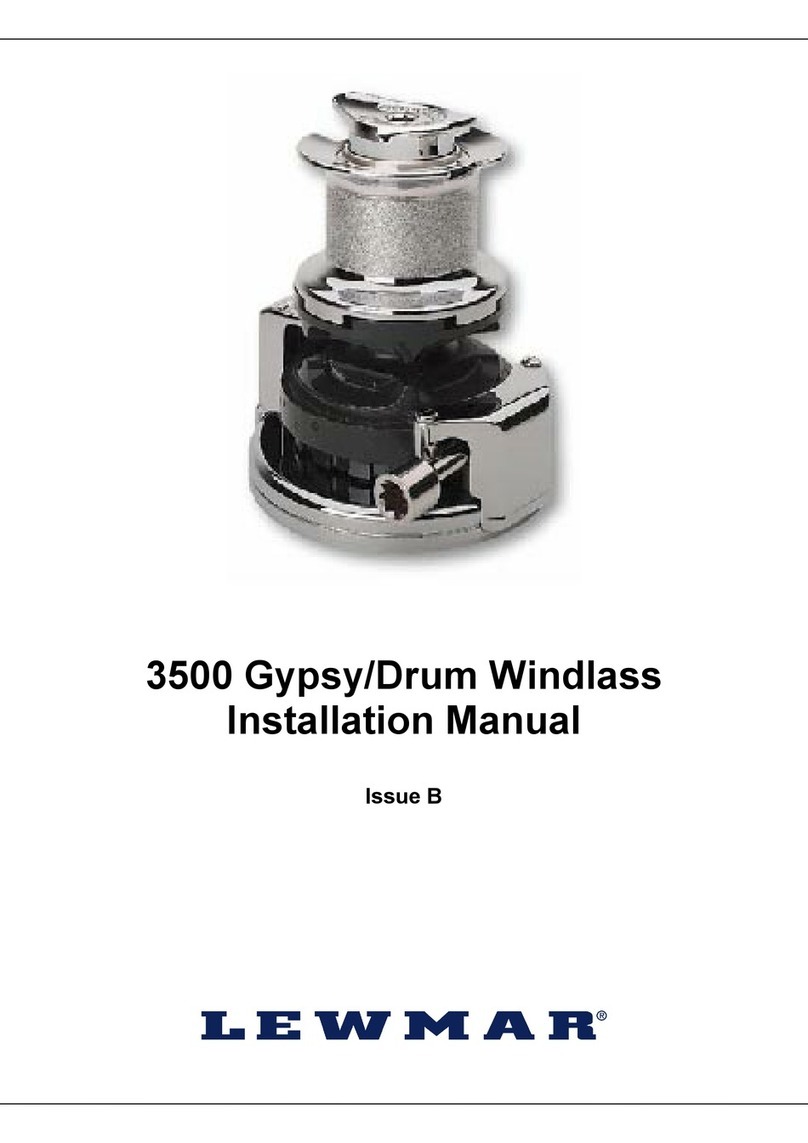

Dear Customer,

Thank you for choosing Lewmar. Lewmar products are world renowned for their quality, technical innovation and

proven performance. With a Lewmar product you will be provided with many years of outstanding service.

Product support

Lewmar products are supported by a worldwide network of distributors and Authorised Service Representatives.

If you encounter any difficulties with this product, please contact your national distributor, or your local Lewmar

dealer. Details are available at: www.lewmar.com

CE Approvals

For CE approval certificates contact Lewmar.

Important information about this manual

Throughout this manual, you will see safety and product damage warnings. You must follow these warnings

carefully to avoid possible injury or damage.

GB