07

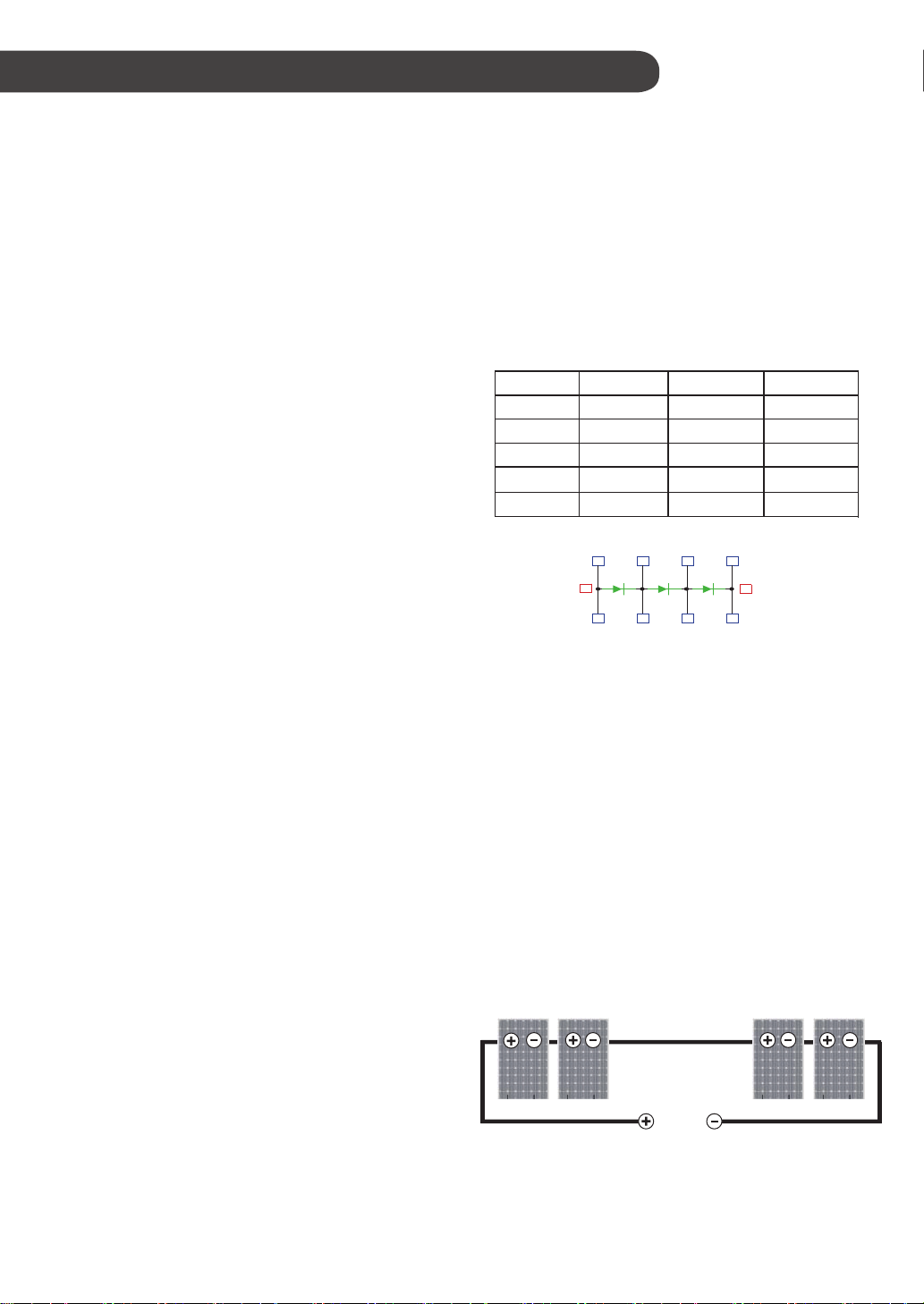

Parallel Connection

•The solar modules may be combined in parallel to

produce the desired current output.

•When modules are combined in parallel, the total

current is equal to the sum of currents from each

module.

•The voltage of each module connected in parallel

should be the same.

•When connecting plural strings of modules in parallel

every series string or solar module must be fused prior

to combining with other strings.

•Abide with all applicable federal, state, and local codes

for additional fusing requirements and limitations on

the maximum number of solar modules in parallel.

•Maximum series fuse rating is refer to “Product

•

for the protection of the module and cables from over-

current for prevention of unbalanced string voltage.

•A multiplying factor is required for increased output

of the PV modules. Under normal conditions, a PV

module is likely to experience conditions that produce

more current and/or voltage than reported at standard

test conditions. The requirements of the National

Electrical Code (NEC) in Article 690 shall be followed

to address these increased outputs. In installations

not under the requirements of the NEC, the values

of Isc and Voc marked on this PV module should

be multiplied by a factor of 125% when determining

component voltage ratings, conductor ampacities,

fuse sizes, and size of controls to the PV output.

•Depending on national directives, additional safety

factors might be applicable for over current protection.

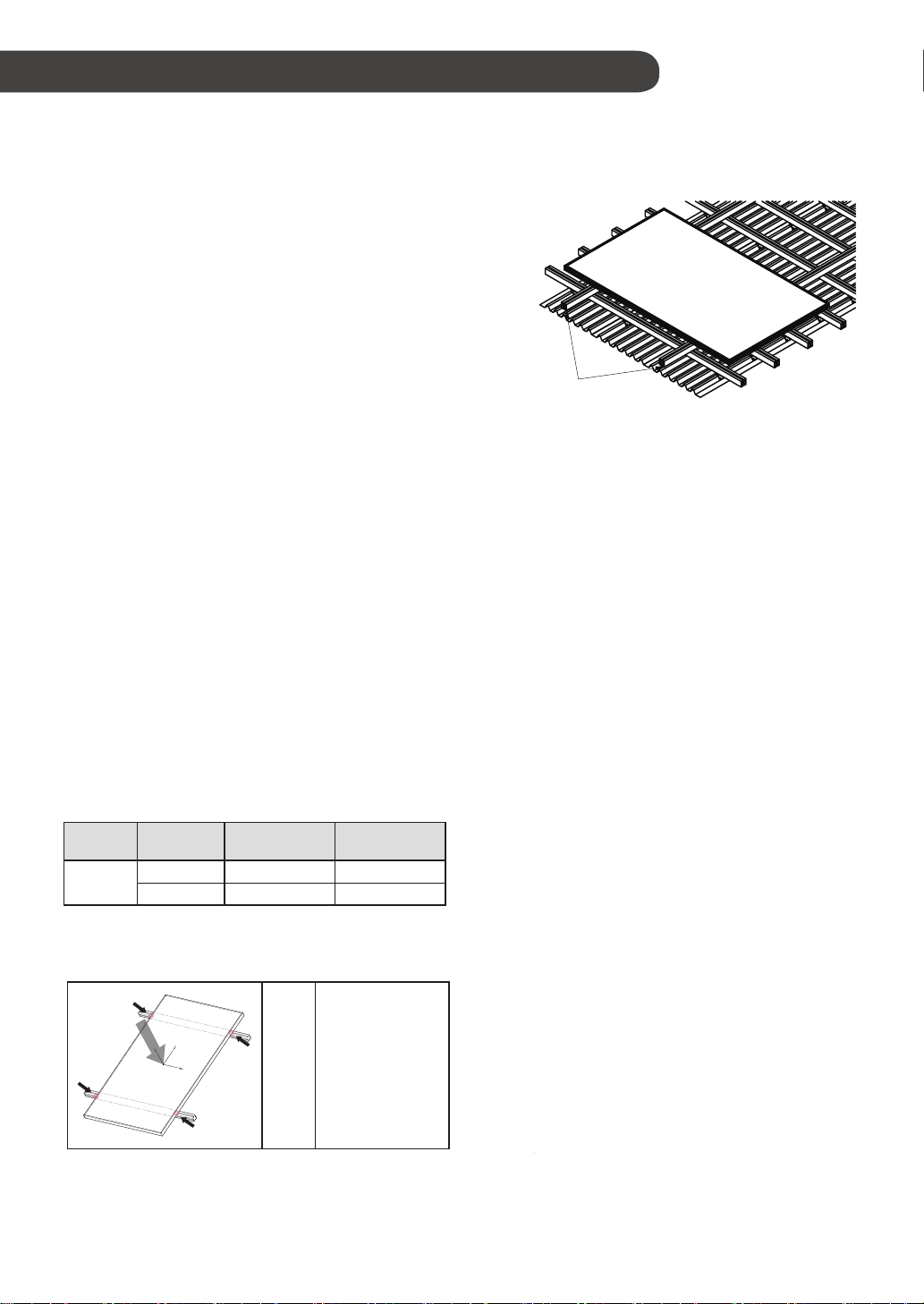

Earth Grounding

•All work must be conducted in conformance with all

Federal, State, and local codes and standards.

•Grounding works should be performed by an

authorized installer for the safety and maintenance of

the system in accordance with all national, state and

local electrical codes and regulations and standards.

•

and location of grounding holes is provided in “Product

•One M4 stainless steel bolt, one nut, one spring

washer and 12 AWG Cu wires are recommended per

mounting hole.

•Where common grounding hardware (nut, bolts,

washers) is used to attach a listed grounding device,

the attachment must be made in conformance with the

grounding device manufacturer’s instructions.

•All hardware should be consist of corrosion resistant

material such as stainless steel.

•There is an earth hole on the edge of the module

frame. Using this hole, an earth conductor and the

solar module frame may be recommended to be

connected and earthed as the below drawing.

•All screws and nuts shall be tightened to a torque of

•To prevent electric shock and fire, a protective ground

must be done on the frames of solar modules and arrays

safety class II. The national directives must be respected.

although the solar modules from LG meet the conditions of

4~5 N∙m.

Module frame

Bolt

Flat washer

Star washer

Cup washer

Grounding wire

Spring washer

Nut

Flat washer

Specifications; page 11”.

Parallel configuration is not limited if proper measures

are taken to block the reverse current flow, e.g. fuses

Parallel connection for more current

-+

…………

+-

+

--

+-

+

General Wiring

•LG Electronics recommends that all wiring be double

insulated with a minimum rating of 90°C (194°F).

•

•The minimum size should be determined by the

applicable codes.

•LG Electronics recommends a size no smaller than

4mm .

2

All wiring should use a flexible copper (Cu) conductor.

Specific information on the solar module dimensions

Specifications”.

washer, two flat washers, one cup washer, one star