ENGLISH

3

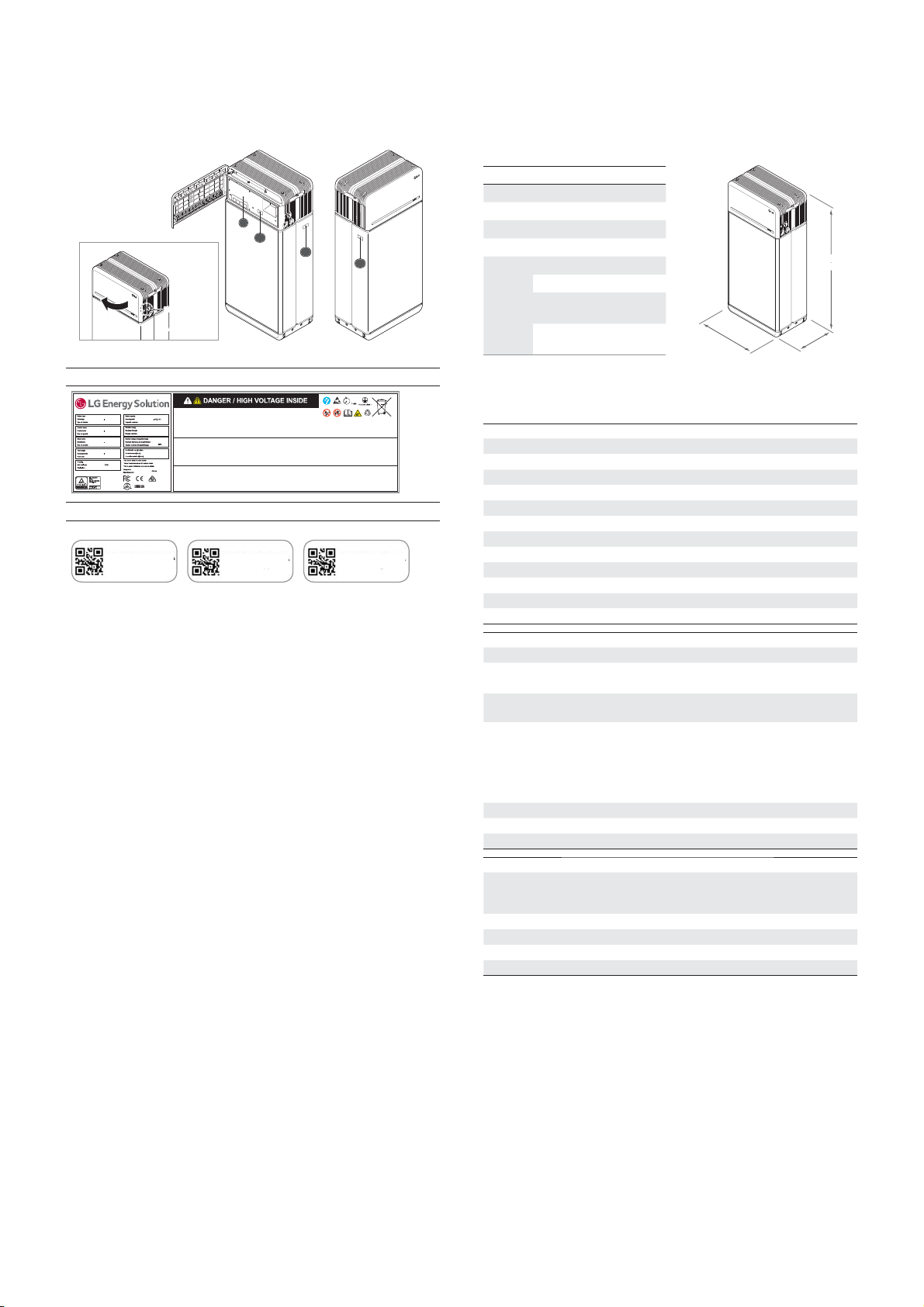

1 Safety

1.1 Symbols

Caution, risk of electric shock

'RQRWSODFHRULQVWDOOQHDUÀDPPDEOHRUH[SORVLYHPDWHULDOV

Install the product out of reach of children

Read the instruction manual, in its entirety, before starting installation

and operation

Heavy weight may cause serious back injuries

Do not dispose of the product with household waste

Recyclable

Disconnect the equipment before carrying out maintenance or repair

Observe precautions for handling electrostatic-sensitive devices

Protective Class 1

Caution, risk of electric shock, energy storage timed discharge.

1.2 Safety Instructions

For safety reasons, installers are responsible for familiarizing themselves with the contents of

this document and all warnings before performing installation and servicing.

1.2.1 General Safety Precautions

Over-voltages or wrong wiring can damage the battery pack and cause combustion which can

be extremely dangerous.

$Q\W\SHRISURGXFWEUHDNGRZQPD\OHDGWRDOHDNDJHRIHOHFWURO\WHVRUÀDPPDEOHJDV

$YRLGLQVWDOOLQJWKHEDWWHU\SDFNZKHUHÀDPPDEOHPDWHULDOVDUHVWRUHG'RQRWLQVWDOOLQSODFHV

where explosive gas or chemicals are present.

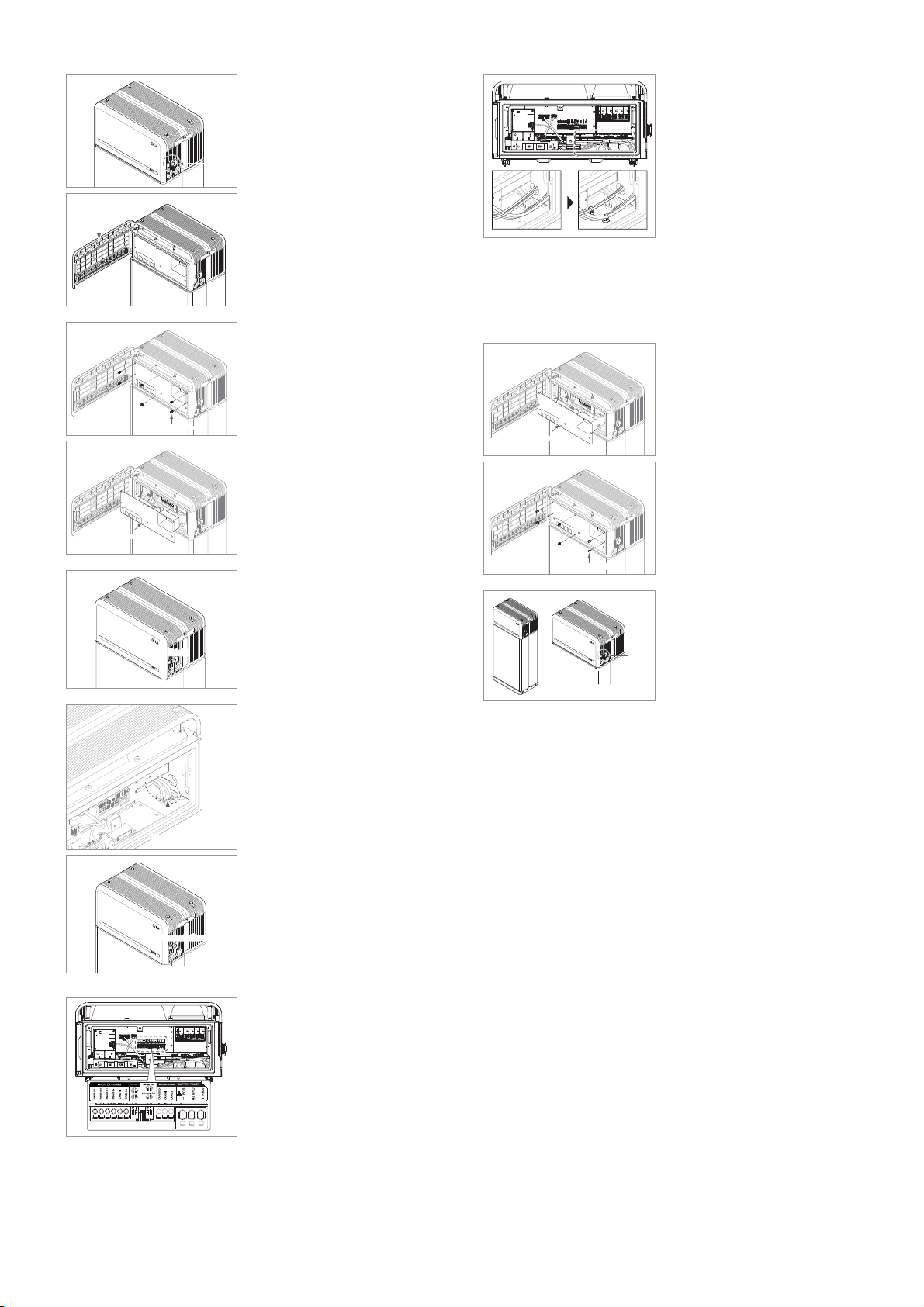

During installation of the battery, the utility grid and solar input must be disconnected from the

%DWWHU\3DFNZLULQJ:LULQJPXVWEHFDUULHGRXWE\TXDOL¿HGSHUVRQQHO

%DWWHU\SDFNVKRXOGRQO\EHVHUYLFHGE\TXDOL¿HGSHUVRQQHO

The electronics inside the battery pack are vulnerable to electrostatic discharge.

Be sure to be grounded before handling the battery pack.

Read the label with Warning Symbols and Precautions, which are visible under the Battery

Cover (see Section 1.3 Warning Label).

1.2.2 Battery Handling Guide

'RQRWH[SRVHWKHEDWWHU\WRDQRSHQÀDPH

'RQRWSODFHWKHSURGXFWQHDUÀDPPDEOHPDWHULDOVVXFKDVDQ\OLTXLG¿OOHG

petroleum containers, compressed natural gas/ propane/ welding fuel tanks, natural

gas supply lines, oxygen tanks, swimming pool chemicals, home furnaces, or

boilers, gas cans/kerosene cans, kerosene/oil powered portable heaters, oil rags,

fuel oil tanks, or garbage bins.

Do not expose or place the product near water sources.

Do not store or install the product in direct sunlight.

Install the product in an area with enough ventilation around the product.

Do not install the product in living area of dwelling units or in sleeping areas.

Store in a cool and dry place. (Do not store in greenhouses or storage areas for

KD\VWUDZFKD൵DQLPDOIHHGIHUWLOL]HUYHJHWDEOHVRUIUXLWSURGXFWV

6WRUHWKHSURGXFWRQDÀDWOHYHOVXUIDFH

Store the product out of reach of children and animals.

Store the product in clean environment, free of dust, dirt and debris.

'RQRWGLVFRQQHFWGLVDVVHPEOHRUUHSDLUWKHSURGXFWE\XQTXDOL¿HGSHUVRQQHO

2QO\TXDOL¿HGSHUVRQDODUHDXWKRUL]HGWRKDQGOHLQVWDOODQGVHUYLFHWKHSURGXFW

Do not damage the product by dropping, deforming, impacting, cutting or

SHQHWUDWLQJZLWKDVKDUSREMHFW'RLQJVRPD\FDXVHD¿UHRUOHDNDJHRI

electrolytes.

Do not touch the product if liquid spills on it. There is a risk of electric shock.

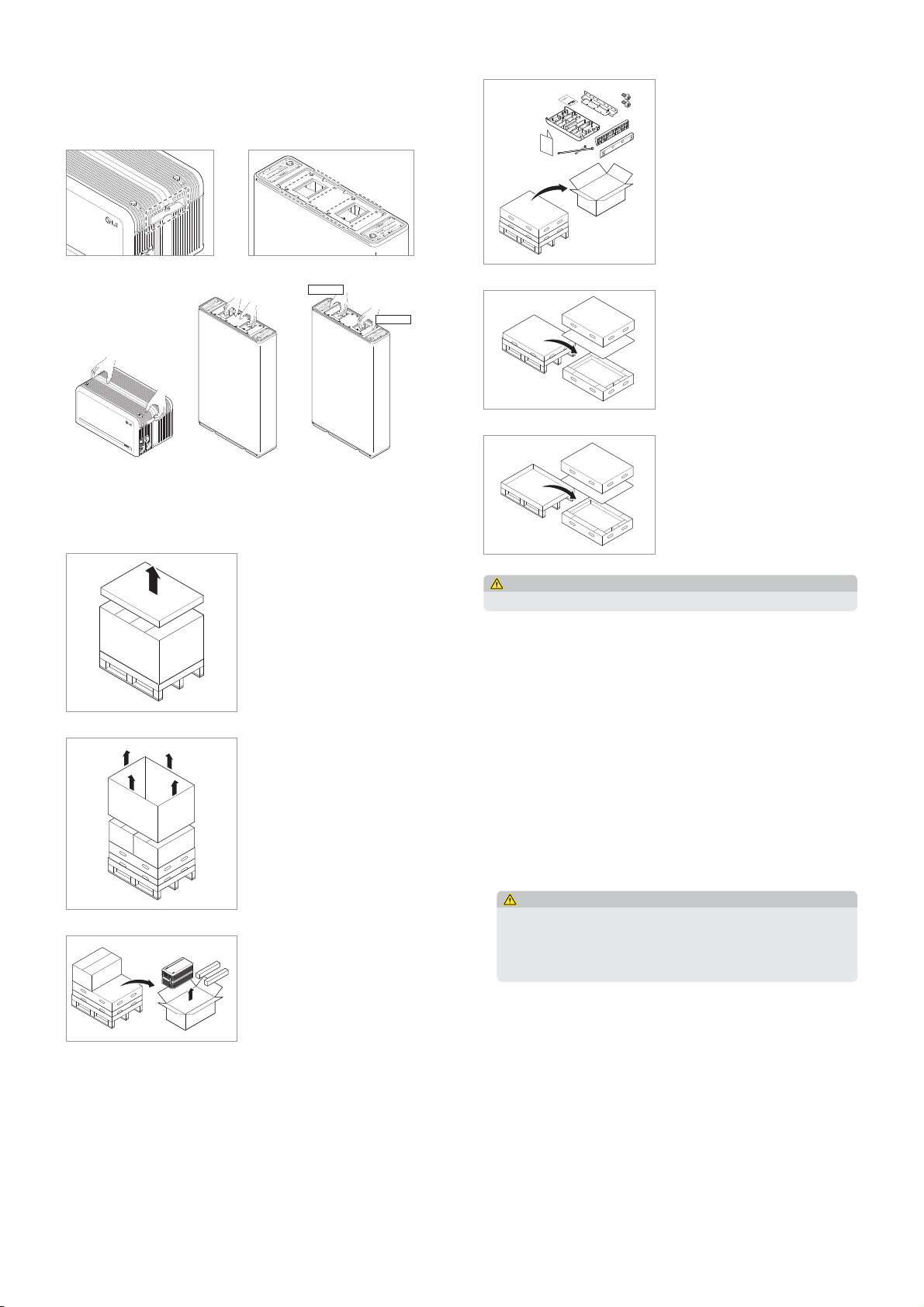

7KHEDWWHU\UHTXLUHVDGHTXDWHFOHDUDQFHIRULQVWDOODWLRQFDEOLQJDLUÀRZVDIHW\DV

detailed in 3.1.8 system clearance

(For wall-mounted option, keep lower clearance area free from foreign materials)

The outer cable connection hole should be sealed to prevent ingress of foreign

objects.

Do not step on the packaging or the product may be damaged.

'RQRWSODFHDQ\IRUHLJQREMHFWVRQWRSRIWKH%DWWHU\3DFNDQGRQWKHFRROLQJ¿Q

Do not put the battery pack upside down on the ground.

Do not connect the power cables at the terminal block in the opposite direction.

Do not charge or discharge a damaged battery.

If the product is installed in a garage or carport, ensure there is adequate clearance

from vehicles.

7KHEDWWHU\SDFNKDVEHHQFHUWL¿HG,3DQGFDQEHLQVWDOOHGLQGRRUVDVZHOO

as outdoors. However, if installed outdoors, do not allow the battery pack to be

exposed to direct sunlight or water sources, as they may cause:

- Power limitation phenomena in the battery (with a resulting decrease in energy

production by the system).

- Premature wear of the electrical/electromechanical and mechanical components.

- Reduction in performance, performance warranty and possible damage of the battery

Only use the product with a authorized inverter by LG Energy Solution.

For a list of compatible inverters, visit the LG ESS Battery Website by the URL

below and check the ‘Home Battery’ > ‘Product Info’ menu.

https://www.lgessbattery.com/us (in case of North America)

https://www.lgessbattery.com/au (in case of Australia)

https://www.lgessbattery.com/eu (in case of all EU-countries in general)

https://www.lgessbattery.com/de (in case of Germany)

https://www.lgessbattery.com/it (in case of Italy)

https://www.lgessbattery.com/es (in case of Spain)

Do not connect any AC conductors or photovoltaic conductors directly to the

battery pack. The battery pack is only to be connected to the inverter.

The product should be installed in accordance all applicable local standards and

regulations

Follow local ordinance when installing in a garage for vehicle clearance [min.

3ft(915mm)]

1.2.3 Response to Emergency Situations

The Product includes internal fault mechanisms designed to prevent failures and subsequent

risk hazards. However, LG Energy Solution cannot guarantee safety performance if the Product

was ever exposed to abuse, damage or negligence, before or after it was put into operational

use.

If a user happens to be exposed to the internal materials of the battery cell, the

following actions are recommended.

In case of inhalation: Leave the contaminated area immediately and seek medical

attention.

In case of contact with eyes: Rinse eyes with running water for 15 minutes and

seek medical attention.

In case of contact with skin: Wash the contacted area thoroughly with soap and

seek medical attention.

In case of ingestion: Induce vomiting and seek medical attention.

,ID¿UHEUHDNVRXWDWWKHORFDWLRQZKHUHWKHEDWWHU\SDFNLVLQVWDOOHGSHUIRUPWKHIROORZLQJ

countermeasures.

8WLOL]H¿UHH[WLQJXLVKLQJPHGLD

A respirator is not required during normal operation.

8VHDQ)0RU&2H[WLQJXLVKHUIRUEDWWHU\¿UHV

8VHDQ$%&¿UHH[WLQJXLVKHULIWKH¿UHLVQRWIURPWKHEDWWHU\DQGKDVQRW\HWVSUHDGWRLW

)ROORZSURSHU¿UH¿JKWLQJLQVWUXFWLRQV

1. ,ID¿UHRFFXUVZKHQFKDUJLQJEDWWHULHVSURYLGHGLWLVVDIHWRGRVRGLVFRQQHFW

WKHEDWWHU\SDFNFLUFXLWEUHDNHUWRVKXWR൵WKHSRZHUFKDUJH

2. ,IWKHEDWWHU\SDFNLVQRWRQ¿UH\HWH[WLQJXLVKWKH¿UHEHIRUHWKHEDWWHU\SDFN

FDWFKHV¿UHSUHIHUDEO\ZLWKZDWHU

3. ,IWKHEDWWHU\SDFNLVRQ¿UHGRQRWWU\WRH[WLQJXLVKLWDQGHYDFXDWHSHRSOH

from the premises immediately.

WARNING

There may be a possible explosion when batteries are heated above 150°C. When a

battery pack is burning, it will leak poisonous gases. Do not approach it.

(൵HFWLYHZD\VWRGHDOZLWKDFFLGHQWV

2QODQG3ODFHWKHGDPDJHGEDWWHU\LQWRDVHJUHJDWHGSODFHDQGFDOO\RXUORFDO¿UH

department or service engineer.

In water: Stay out of the water and do not touch anything if any part of the battery, inverter,

or wiring is submerged.

Do not use the submerged battery again. Contact your service engineer for assistance.