FlexPower Generation 2 DC Power System Installation Manual

4 5

Installation and Operation

bm DataLink Connection

This is the connector for the DataLink connection. It allows optional

programming and monitoring of the FPO power supply via an optional

NetLink network module.

See the instructions for the Netlink module for more information.

bn FAI Input Connections (TB2)

These terminals accept the optional FAI / Access Control input for

controlling the DC2 output and any FAI capable accessory boards

connected to the FPO power supply. The terminals are removable

and are labeled on the PC board. These terminals accept AWG14 –

AWG22 wire. See Section 1.3. Connections are as follows:

• I+ & I– TerminalsThese terminals are the input terminals for the

FAI Input. The FAI input is activated when a voltage between 9 and

30 volts is applied across these terminals in the correct polarity. See

Section 1.3 - FAI Input Usage for more information.

• V+ & V– TerminalsThese terminals are a low-current auxiliary volt-

age output and are typically used with a dry contact or open collector

for activating the FAI Input's I+ and I- terminals.

• L TerminalsLatch Reset contact input. If a latching FAI Input is

desired, a normally closed contact is placed across these terminals.

When the FAI Input is activated, it will latch in the activated state until

this contact is momentarily opened. If the latching feature is not

desired, leave these terminals open.

bo

DC1 & DC2 – Blue/Green

These LEDs light when voltage is available on the DC1 and DC2

output terminals. The DC2 LED will extinguish if the output is

disabled via the FAI input. This LED is dual color and indicates the

output voltage as follows:

• BlueThe output is set to 24V

• GreenThe output is set to 12V

bp

Battery Type Selection

This jumper selects the type of battery being used. Select SLA for

Sealed Lead Acid/Gel type batteries. Select LFP for Lithium Iron

Phosphate batteries.

bq

Battery Presence Detection (JP3)

The BAT DET jumper enables or disables Battery Presence fault

detection as follows:

• Position 1 (jumper ON) Enable Battery Detection

• Position 2 (jumper OFF) Disable Battery Detection

IEnabled (Postion 1) is the factory default position which will

cause a fault to occur if a battery is not connected.

Battery Presence fault detection indicates a fault when the backup bat-

tery is disconnected from the FPO power supply. If no backup battery

is being used, this jumper should be placed in position 2.

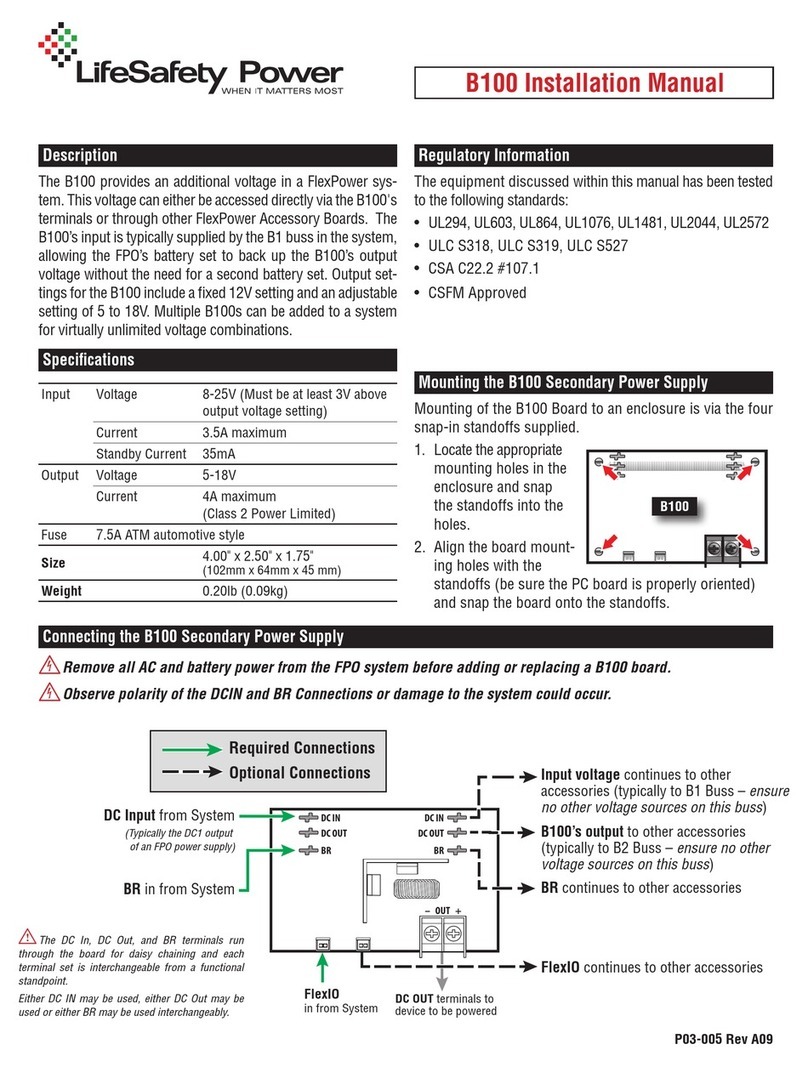

br FlexConnect Power Connections

Faston connectors for the power connection to any accessory boards

to be connected. Pre-terminated power leads are provided with the ac-

cessory boards. For more information, see the instruction manual for

any accessory boards used in the system. Connections are as follows:

• DC1This faston provides a constant voltage output for con-

nection to the accessory boards.

• BRThe DC Common (DC Ground) for the FPO power supply.

• DC2This faston provides an FAI controlled output that oper-

ates in conjunction with the DC2 output terminals. This con-

nection is typically only used in single voltage systems with D8

accessory boards. See the sections on the FAI Input and DC2

Output Configuration for more information.

• V+/V- (FPO150/250 only)Faston connectors for powering a

NetLink network module. Do not power the NetLink module

from the DC1 or DC2 buss. See the NetLink module manual for

more information.

bsDC2 Output (TB1)

The DC2 output may optionally be controlled by the FAI input. The

full current of the FPO is available on this terminal. If not using

the FAI input, the DC2 output may be used to provide continuous

power. See the section on the FAI Input for more information. This

terminal accepts AWG12 – AWG18 wire.

IWhen powering magnetic loads such as maglocks, door strikes,

solenoids, etc, each of these loads must have a reverse protection

diode either built-in or external to the device.

bt DC1 Output (TB1)

The main DC output of the FPO power supply. The full current of the

FPO is available on this terminal at all times and is unaffected by the

FAI input. This terminal accepts AWG12 – AWG18 wire.

IWhen powering magnetic loads such as maglocks, door strikes,

solenoids, etc, each of these loads must have a reverse protection

diode either built-in or external to the device.

ck Battery Connection (BAT+ & BAT–)

Faston connectors for connection of the backup battery set.

Pre-terminated battery leads are provided. See the Specifications

section for the maximum battery size. If no battery set is to be

used, ensure the BAT DET jumper is off to prevent a fault condition

from being annunciated. The generation 2 FPO power supply has

built-in low battery disconnect to prevent deep discharge of the

batteries and to prevent damage to sensitive equipment.

HSelect the proper battery type before connecting a battery set

to the FPO power supply. See #15

HNote that FPO75 PCB and FPO150-250 PCB's have different

battery connection layouts.

HAn FPO set for a 12V output requires a 12V battery set. An FPO supply set

for a 24V output must use a 24V battery set (two 12V batteries in series).

HObserve polarity or damage to the system will occur.

HIt is the installer’s responsibility to determine the proper bat-

tery size for the installation. See the Specifications section for

standby current requirements.

cl Battery Fuse

This fuse is in series with the battery connection. Replace with only the

same type and rating.

cm REV BAT (D20) – Yellow

This LED lights if the backup battery set is connected in the

reverse polarity. The lighting of this LED will also be accompanied

by the rupture of the battery fuse (F4) and the lighting of the SYS

FLT LED.