FlexPower Vantage Standard Power System - Installation Manual 2

Symbol Definitions

The following symbols are used throughout this manual:

h This symbol is intended to alert the installer of shock

hazards within the enclosure. Service should only be

performed by qualified service personnel.

iThis symbol is intended to alert the installer of important

information intended to help the installer avoid personal

injury or property damage.

Warnings

h Installation and service should be performed only by quali-

fied service personnel and should conform to all local codes.

h To reduce the risk of electric shock or fire, do not

expose this equipment to rain or moisture.

i This equipment shall be installed in a manner which

prevents unintentional operation by employees,

cleaning personnel, or others working in the prem-

ises, by falling objects, customers, building vibration,

or similar causes.

i This equipment is not intended for use within the patient

care areas of a Health Care Facility.

h Replace fuses only with the same type and rating as

indicated in the specifications section of this manual.

i To prevent impaired operation, ensure that all wiring is

routed and secured to prevent accidental open or short

circuit conditions.

i The system and any batteries (if used) should be tested

at least once per year to ensure proper operation.

i Batteries (if used) should be maintained at an ambient tem-

perature of between 32 and 120 degrees Fahrenheit (0-49

Celsius) or premature loss of battery power could occur.

iTest and verify output voltage before connecting the

load.

R

The equipment discussed within this manual has been

tested to the following standards:

• UL294, UL603, UL1076

• ULC S318, ULC S319

• CSA C22.2 #107.1, CSA C22.2 #205

FCC Information

Note: This equipment has been tested and found to com-

ply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules and ICES-003. These limits are

designed to provide reasonable protection against harm-

ful interference when the equipment is operated in a com-

mercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of

this equipment in a residential area is likely to cause harm-

ful interference in which case the user will be required to

correct the interference at his own expense.

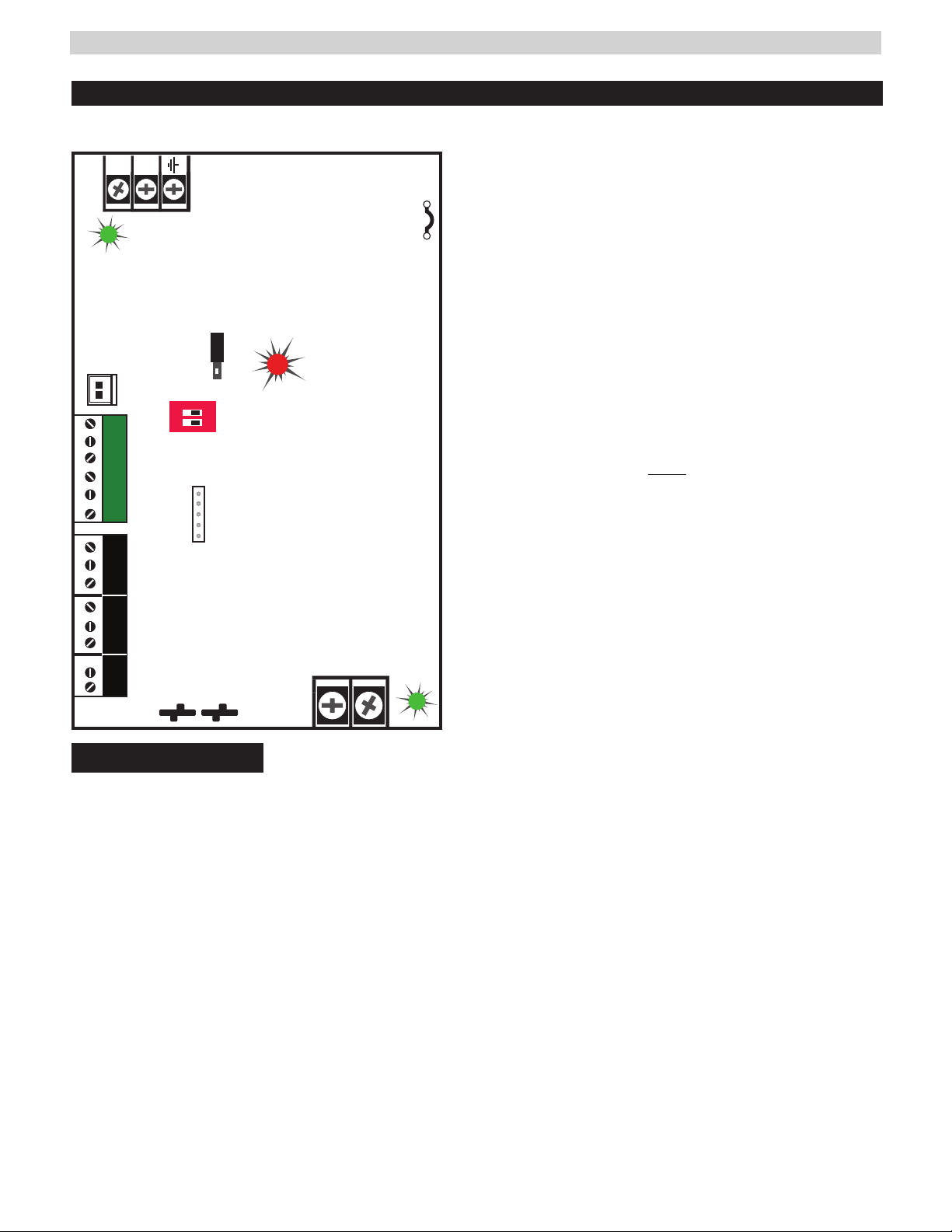

Conventions Used Within this Manual

Positional information (e.g. top, bottom, up, down, left,

right, etc.) is referenced with the board or enclosure in the

orientation shown in the illustrations in this manual.

Enclosure Mounting

Mounting an Enclosure

Use the following procedure when mounting a wall-mount enclosure.

1. (Optional) Remove the enclosure’s cover.

2. Locate the top keyhole mounting holes in the back of the enclosure.

3. Mark and pre-drill the locations for the keyholes in the

mounting surface.

4. Partially install two fasteners appropriate for the sur-

face on which the enclosure is being installed. Leave the

heads of the fasteners approximately ¼" out from the

surface. Minimum fastener size should be #10 or larger.

5. Hang the enclosure on the two fasteners and mark the

locations of the remaining mounting holes.

6. Remove the enclosure and pre-drill the locations for the

remaining mounting holes.

7. Re-hang the enclosure on the top mounting fasteners,

start the remaining fasteners and tighten all fasteners.

8. Reinstall the enclosure’s cover, if removed in step 1.

iIt is the installer’s responsibility to determine the

appropriate fastening system for use with the sur-

face the enclosure is being mounted to.

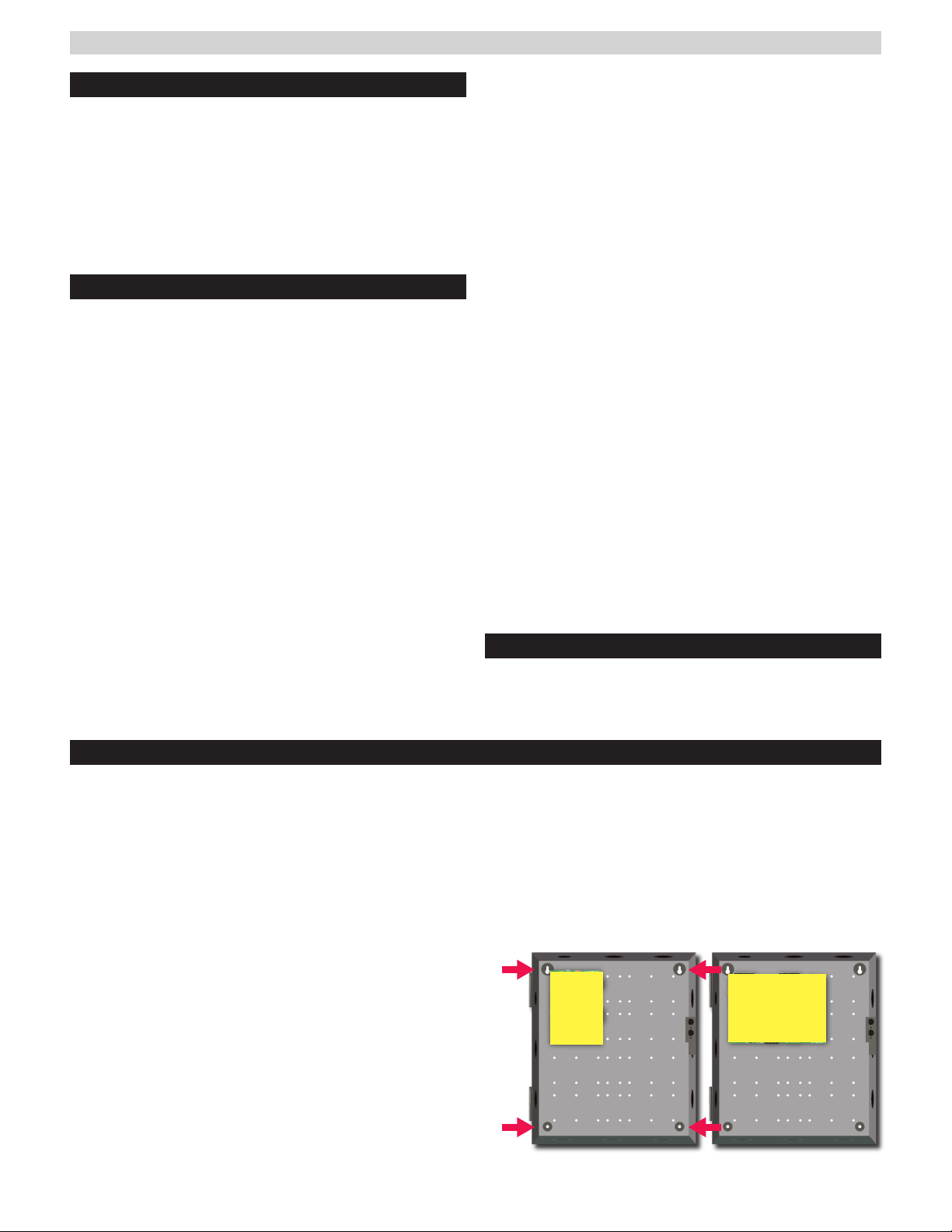

iFor UL1076 applications, after installation is com-

plete, the installer must install the two supplied 1"

long screws to the edge of the enclosure's cover

for additional security.

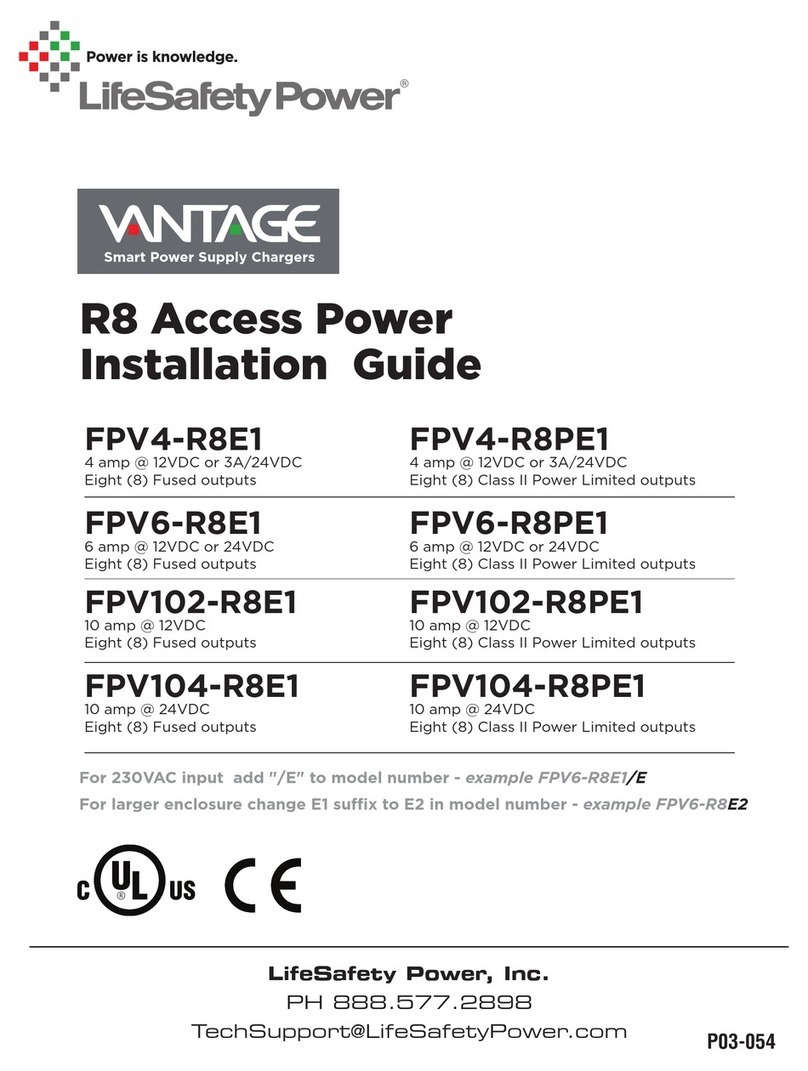

FPV6, 102,

104

FPV4