RH Series Rackmount Helix Installation Manual

iv 1

Installation and Operation

Introduction

DC Product Power Outputs Description

RH75 Series 75W 2 Single Voltage 6A @ 12VDC or 3A @ 24VDC / dual output

RH150 Series 150W 2 Single Voltage 12A @ 12VDC or 6A @ 24VDC / dual output

RH250 Series 250W 2 Single Voltage 20A @ 12VDC or 10A @ 24VDC / dual output

Remote monitoring

RH75-XN 75W 8, 16 Single Voltage / Network 6A @ 12VDC or 3A @ 24VDC / multiple outputs / network

RH150-XN 150W 8, 16 Single Voltage / Network 12A @ 12VDC or 6A @ 24VDC / multiple outputs / network

RH250-XN 250W 8, 16 Single Voltage / Network 20A @ 12VDC or 10A @ 24VDC / multiple outputs / network

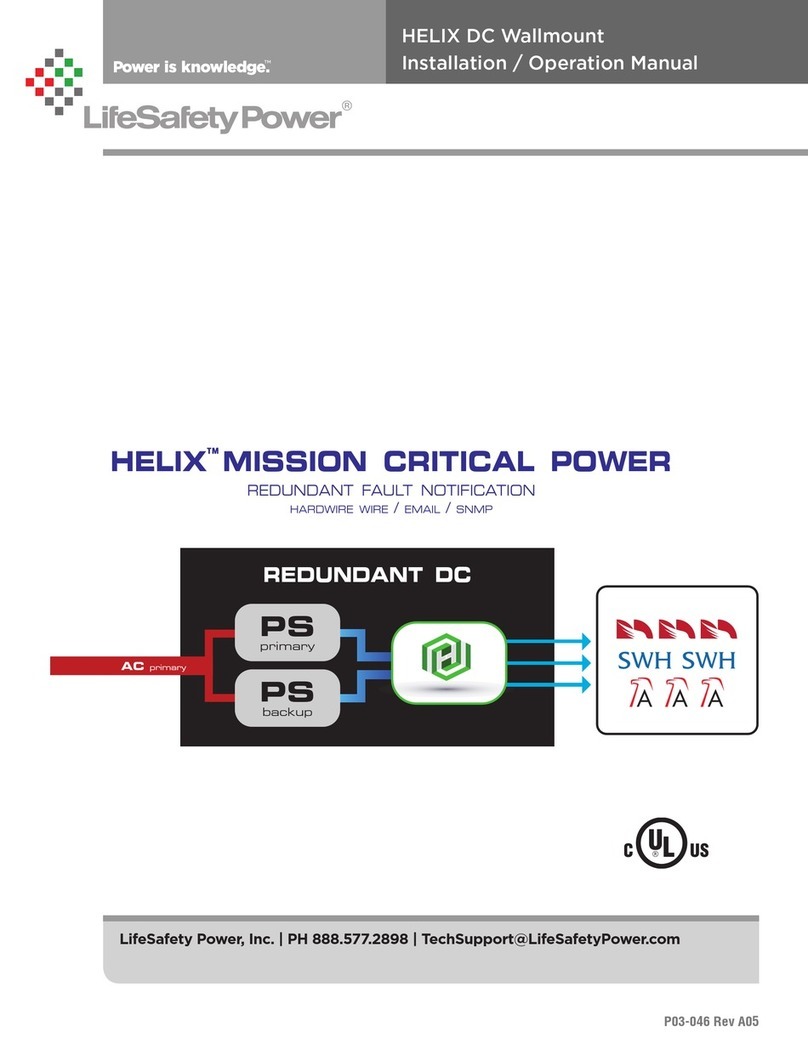

The LifeSafety Power Helix RH rackmount power supplies are

a redundant power source for use in the Access Control indus-

try. Two identical FPO power supplies are combined in a single

enclosure with the Helix module to provide a single output

voltage. In the event of a failure of the main power source, the

Helix module will automatically switch the output to the back-

up FPO power supply. Designed to fit neatly into standard 19"

equipment racks, the streamlined cabinetry and exceptional

features combine to significantly reduce installation and ser-

vice costs. Features include removable terminal strips for field

wiring, input and output surge suppression, automotive blade

fuses for improved reliability, a front removable chassis face

plate for serviceability and is enclosed in a 16 gauge steel 2U

rack mount chassis.

The Helix RH Series of single voltage DC power supplies pro-

vide 12 or 24 VDC power at 75W, 150W and 250W of total

power. They are available with 8 or 16 outputs and the capabili-

ty of remote monitoring of the supply's parameters via internet

or intranet connection. Ideal for Access Control, CCTV, Burglar,

Fire, or Mass Notification applications. Helix provides added

system integrity by automatically switching to the backup

power supply in the event of a problem with the primary power

supply. Each output is fused at 3A, but may be increased up to

7.5A by the installer for powering high power devices.

i Due to the nature of this product and its intended ap-

plications, the limitations and conditions of installation of

the Helix power supply must be fully understood by the sys-

tem planner & installer. Please thoroughly read and under-

stand the following sections before using the Helix power

supply.

Redundancy

The Helix RH series of power supplies adds a layer of redun-

dancy over the typical FPO power supply. Only the FPO power

supply is redundant - any distribution in the system is not re-

dundant. Also, the Helix cannot overcome any problems in the

field wiring or load devices - if a short circuit shuts down the

main supply, the backup supply will also be shut down by this

short circuit.

Primary AC Connection

Both FPO power supplies must be powered from the same AC

branch circuit. Powering the two internal FPO power supplies

from different branch circuits could lead to possible improper

operation and loss of output voltage.

Backup Battery

FPO2 must have battery backup connected for proper opera-

tion. A battery should not be connected to FPO1 - this is to

prevent cycling between FPO1 and FPO2 during battery dis-

charge on loss of AC.

Fault Contacts

The fault contacts of BOTH FPO power supplies must be moni-

tored to annunciate failure of either power supply. The fault

contacts may either be monitored separately or series/paral-

leled as needed for a common fault indication. Use of a Netlink

network monitoring module is also highly recommended.

Product Description

HELIX RH Series

Limitations