Lincoln Electric Excalibur 11018M MR User manual

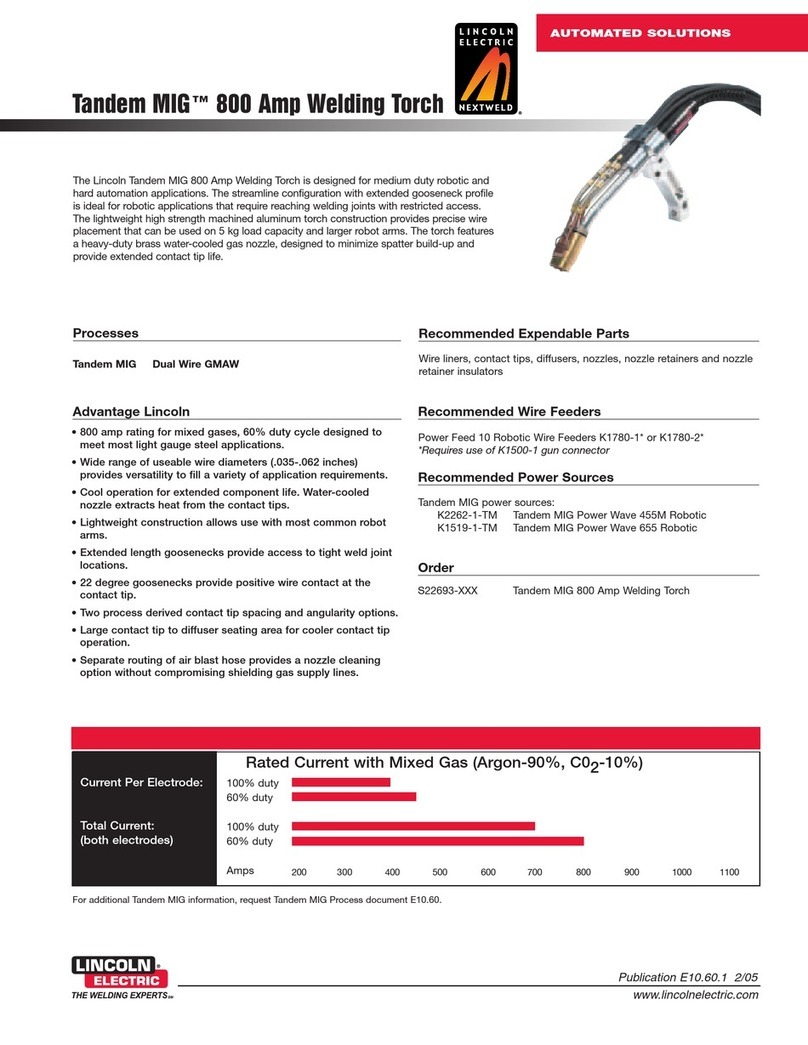

Other Lincoln Electric Welding Accessories manuals

Lincoln Electric

Lincoln Electric MAGNUM 550 User manual

Lincoln Electric

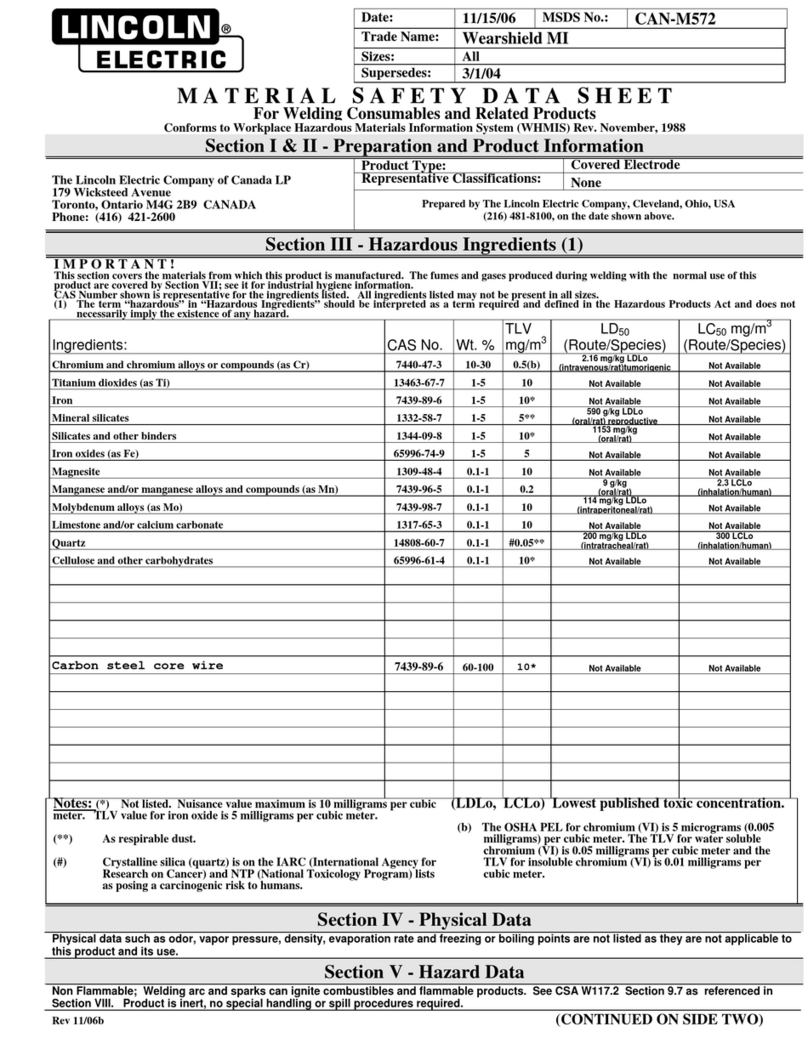

Lincoln Electric Wearshield MI User manual

Lincoln Electric

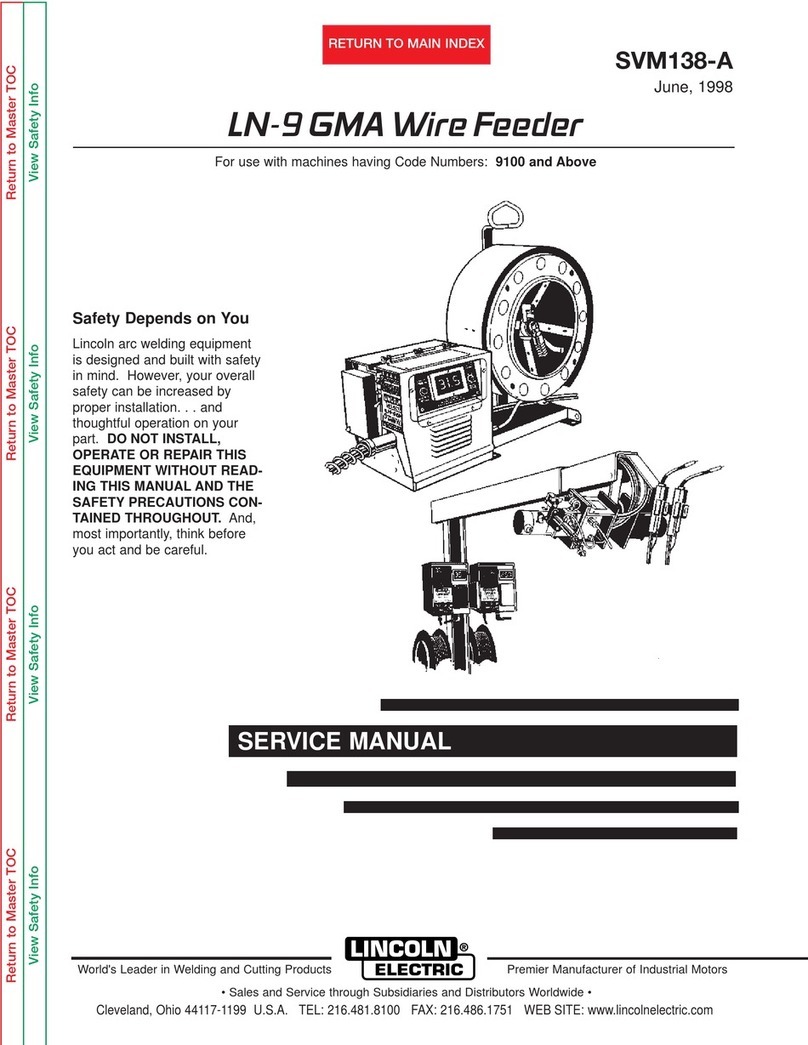

Lincoln Electric SVM138-A User manual

Lincoln Electric

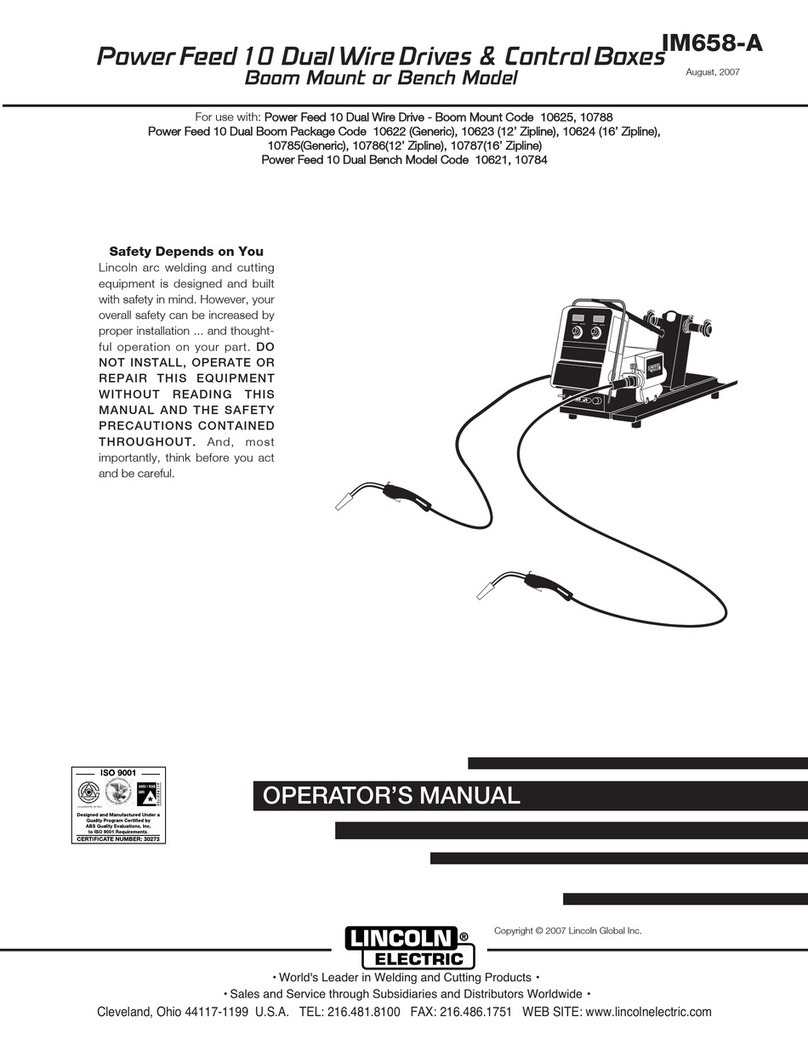

Lincoln Electric IM658-A User manual

Lincoln Electric

Lincoln Electric 900 User manual

Lincoln Electric

Lincoln Electric K3091-1 User manual

Lincoln Electric

Lincoln Electric IM359-G User manual

Lincoln Electric

Lincoln Electric GRAPHICS MAY VARY User manual

Lincoln Electric

Lincoln Electric IM613-B User manual

Lincoln Electric

Lincoln Electric AutoDrive 4R90 User manual

Lincoln Electric

Lincoln Electric Pyrotome SE Mounting instructions

Lincoln Electric

Lincoln Electric LC105 User manual

Lincoln Electric

Lincoln Electric DH-10 User manual

Lincoln Electric

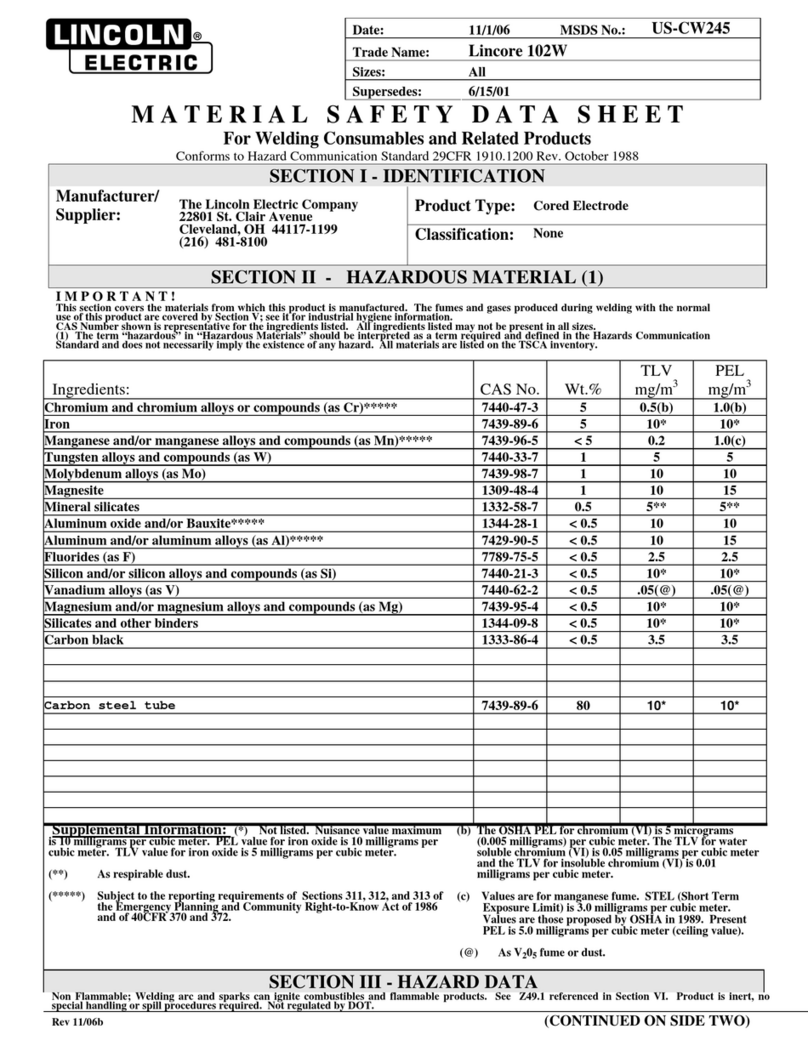

Lincoln Electric US-CW245 User manual

Lincoln Electric

Lincoln Electric PIPELINER LN-23P User manual

Lincoln Electric

Lincoln Electric K3589-1 User manual

Lincoln Electric

Lincoln Electric K3590-1 User manual

Lincoln Electric

Lincoln Electric VIKING 1740 Series User manual

Lincoln Electric

Lincoln Electric US-CW338 User manual

Lincoln Electric

Lincoln Electric AUTO-DARKENING HELMET IM10001 User manual