General Information

Appropriate Use

Use the two-line metering devices of the VSG/VSL series only

for the supply of lubricant in centralized lubrication systems.

Geeneral Safety Instructions

Do not install or remove the metering devices when the

system is under pressure or the pump in operation.

•

Always protect the centralized lubrication system

connected to the pump with a pressure reducing valve.

•

Incorrect operation may lead to damage resulting from

insufficient or excessive lubrication of bearings or

lubrication points.

•

Your own alterations or modifications of an installed

sy stem should only be carried out if approved with the

manufacturer or his appointed dealer.

•

Use only original LINCOLN spare parts or parts

authorized by LINCOLN

Regulations for Prevention of Accidents

•Adhere to the rules valid in the country where the unit

will be in operation.

Installation

For all work at the metering device, observe extreme

cleanliness

–Attach the metering devices to even surfaces without

tension.

When base plates are used (see Accessories), first weld

the base plates without the metering devices and then

attach the metering devices onto them.

–Protect the metering devices from dust and influences of

heat (observe the maximum admissible operating

temperatures).

– The metering devices must be easily accessible for.

check and installation work.

·Before connecting the feed lines to the metering

devices, fill them with lubricant.

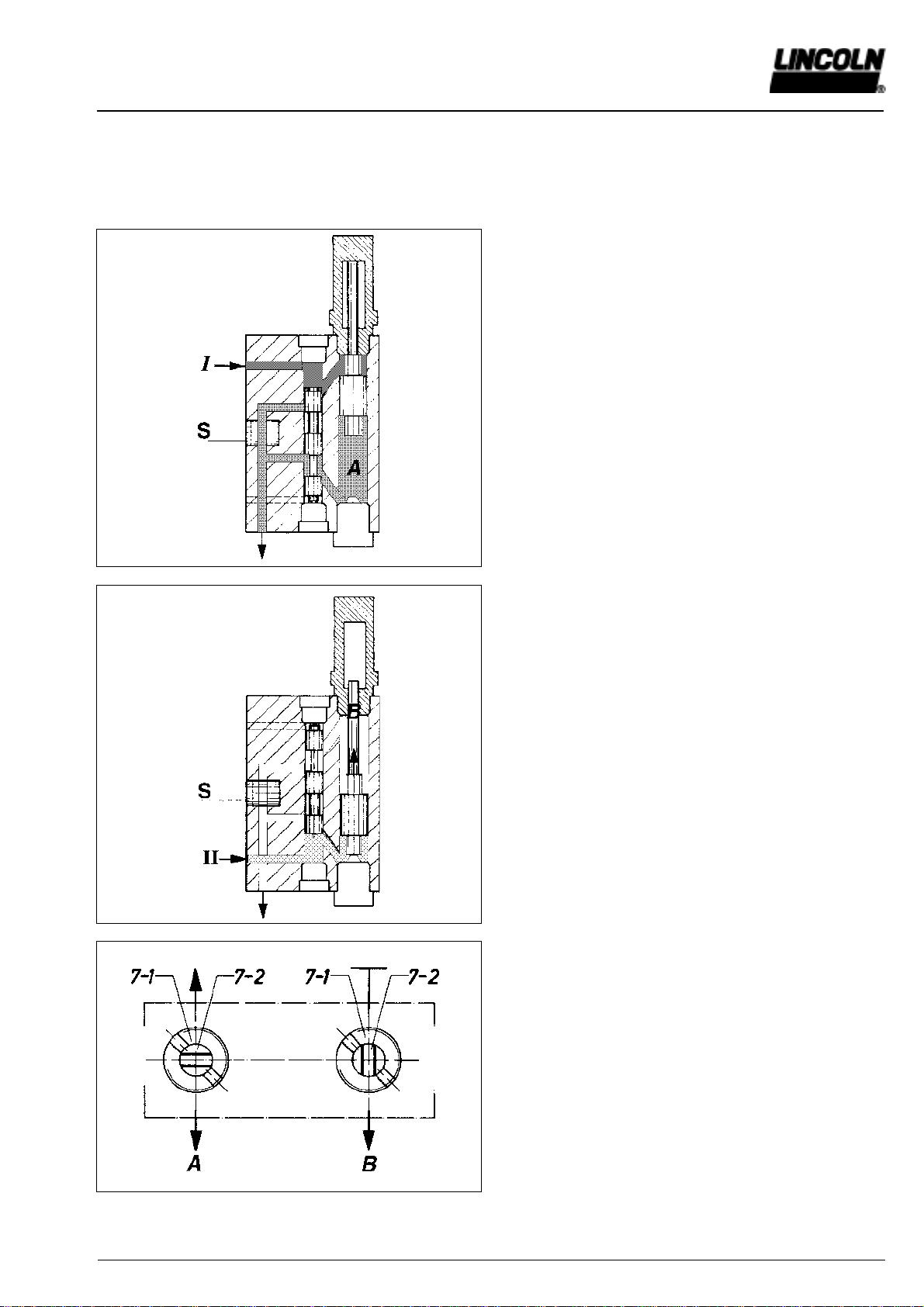

·When connecting the main lines take care to always

connect the same line (I or II) to the same metering

device inlet.

This makes it easier to check of the metering device

because all indicator pins are either in or out after each

cycle.

Table of Contents Page

General information................................................................ 2

Technical data ........................................................................ 3

Model identification................................................................. 5

Description of operation.......................................................... 6

Installation ............................................................................ 10

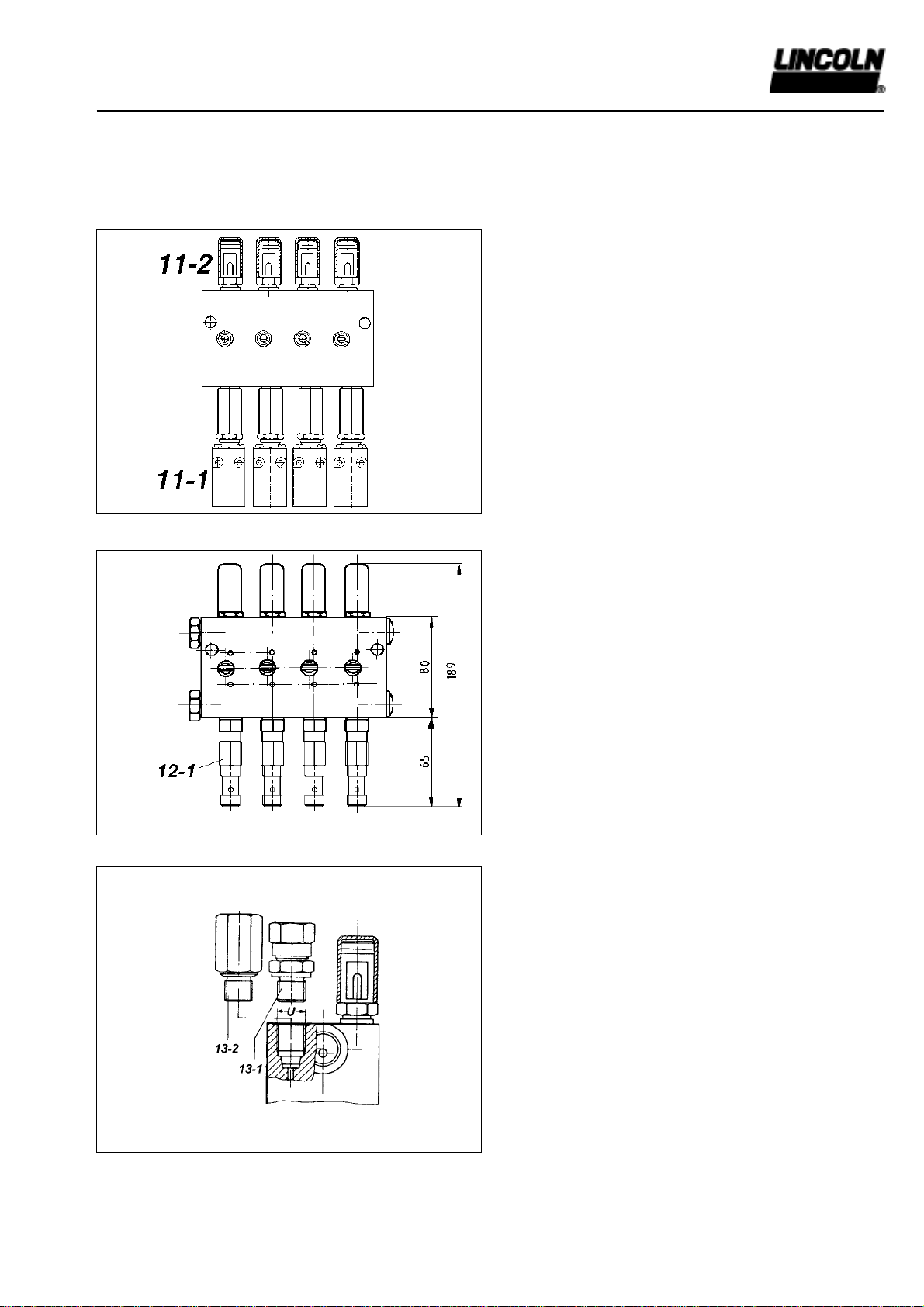

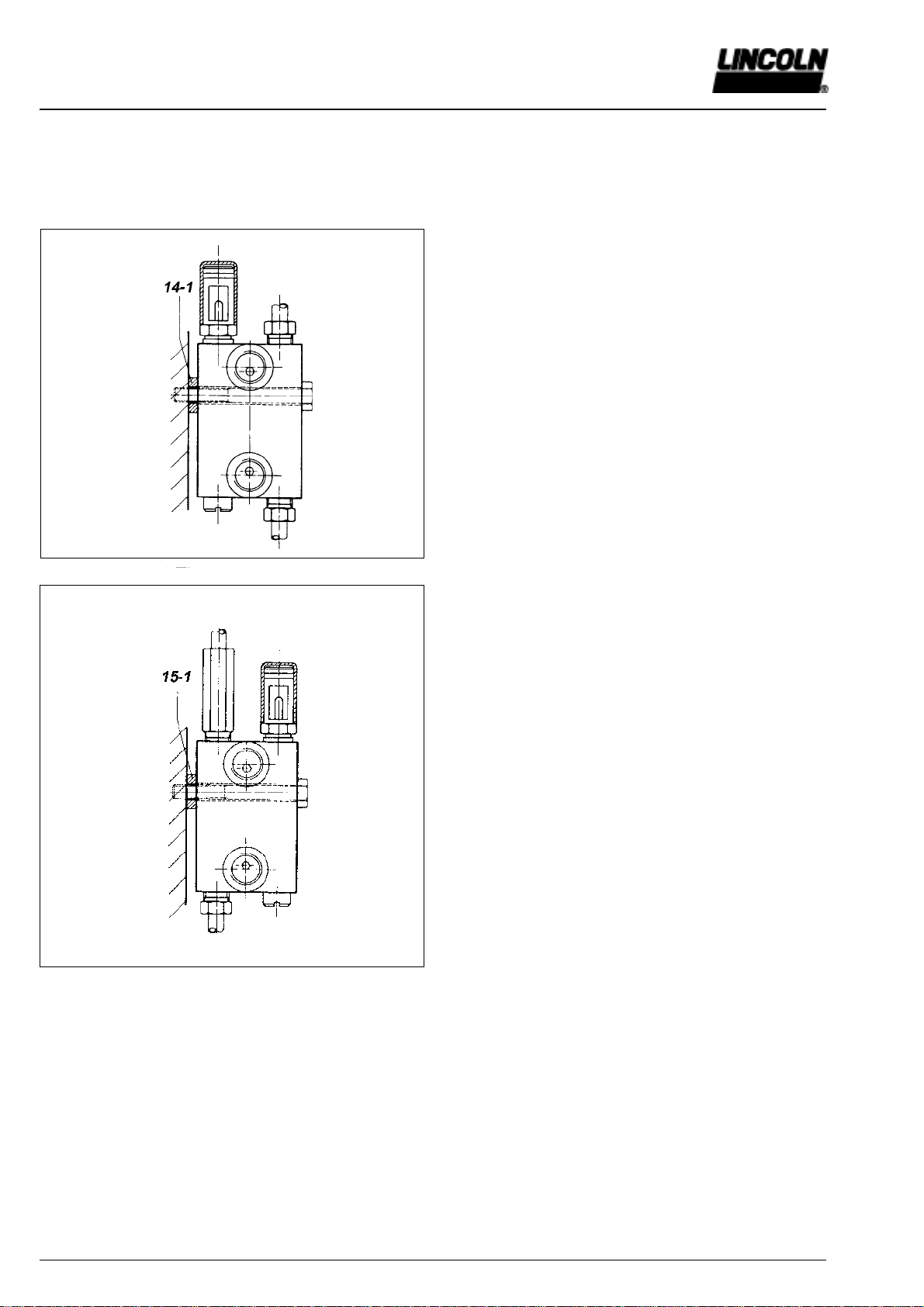

Accessories ...........................................................................11

Spare parts ........................................................................... 12

Operation, Maintenance and Repair

Repairs should be carried out only by qualified persons who

have been charged with the repair work and are familiar with

centralized lubrication systems.

Since the pistons in the metering devices are fit with the

smallest tolerances, the metering device must be replaced

when the pistons are worn.

When synthetic lubricants are used, bear in mind that they

must be compatible with the sealing material of the metering

devices (polyurethane or FKM).

Use only lubricants which are appropriate for centralized

lubrication systems. If in doubt, ask the supplier.

Further Information:

For the VSG-MR version:

Adjusting device with magnetically operated indication of

function (1.2A-18002-A96)

For the VSG-KR-NP version:

Data sheet „Piston detector“ (9.3A-20016-A00)