Form 404248 Page Number - 3

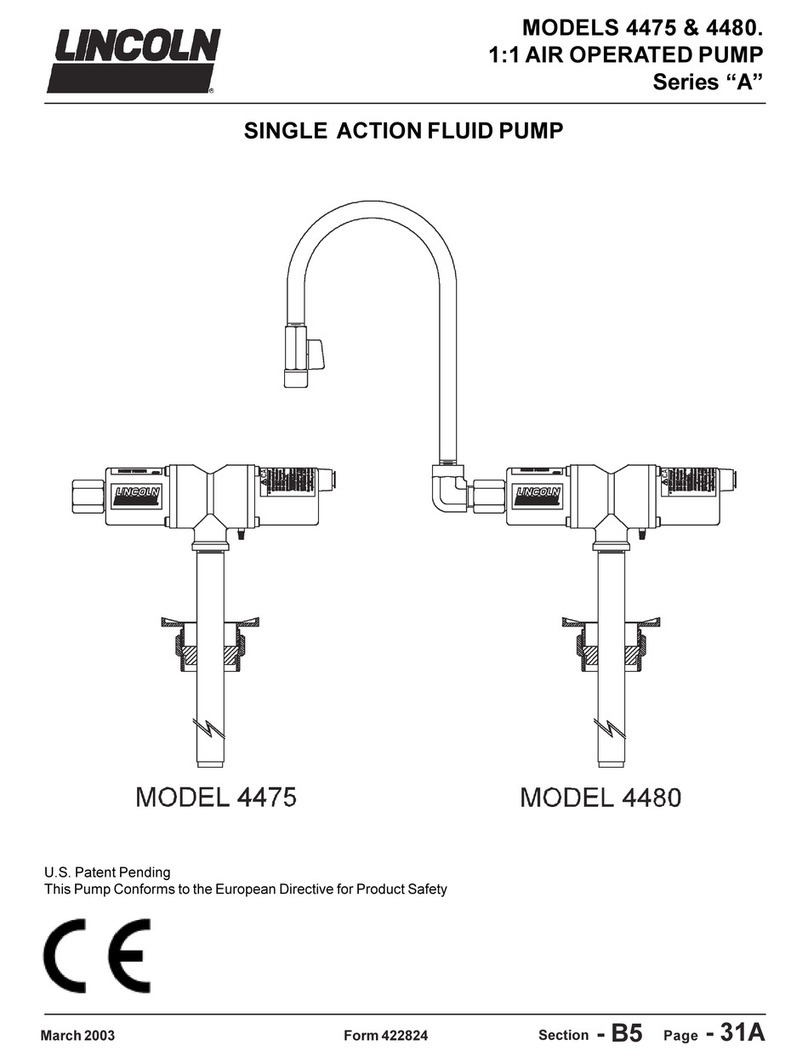

DESCRIPTION

The Lincoln 4100 and 4102 Fluid Evacuation

Systems provide a clean, safe way to evacuate

waste fluids. Both systems feature a corrosion

resistant aluminum double diaphragm pump that

creates a powerful suction to evacuate waste fluids

and transfer them through an enclosed system to

a remote storage tank. The 4100 includes a U.L.

approved pump for transferring used motor oil

or other potentially flammable fluids. Model 4102

includes a non-U.L. listed pump for transferring

non-flammable fluids such as coolant or

windshield cleaner.

The systems can evacuate used fluids from rolling

drain pans, portable oil drain containers and

differentials and transaxles. The pumps are air

operated and can be mounted on any convenient

wall surface. One basic system can be connected

with additional hardware to serve multiple service

bays.

OWNER/OPERATOR RESPONSIBILITY

It is the owner/operator responsibility to properly

use and maintain this equipment.

The instructions and warnings contained in this

manual shall be read and understood by the

owner/operator prior to operating this equipment.

If an owner/operator does not understand English,

the contents of this manual shall be explained in

the owner/ operator’s native language to assure

the owner/operator comprehends.

It is the owners/operators responsibility to maintain

the legibility of all warning and instruction labels.

The owner/operator shall retain this manual for

future reference to important warnings and

installation instructions.

INSTALLATION

Depending on the type of fluid to be evacuated,

the Fluid Evacuation System installation and use

must be in accordance with the Flammable and

Combustible Liquids Code (NFPA 30) and

Automotive and Marine Service Station Code

(NFPA 30A) and must comply with all local, state

and Federal codes.

Also, the United States Government safety stan-

dards have been adopted under the Occupational

Safety and Health Act. These standards should be

consulted, particulary the General Standards, Part

1910, and the Construction Standard, Part 1926.

GROUNDING

To reduce the risk of static electrical sparking,

the system must be grounded. Refer to your local,

state, federal electrical codes for detailed ground-

ing instructions that are applicable to your area

and type of equipment.

WARNING

FAILURE TO HEED THE FOLLOWING WARNINGS

INCLUDING FAILURE TO GROUND EQUIPMENT,

MISUSE, OVER PRESSURIZING, MODIFYING

PARTS, EVACUATING INCOMPATIBLE FLUIDS,

OR USING WORN OR DAMAGED PARTS, MAY

RESULT IN EQUIPMENT DAMAGE AND/OR

SERIOUS PERSONAL INJURY, FIRE, EXPLOSION,

OR PROPERTY DAMAGE.

• Make sure the pump and all other equipment

used or located in the pumping area are

grounded.

• Do not use the system if any static sparking or

electrical shock occurs. Stop the evacuation

immediately and do not use the system until the

problem is corrected.

• Do not exceed the stated maximum working

pressure of the pump or of the lowest rated

component in your system. Do not alter or

modify any part of this equipment.

• Do not attempt to repair or disassemble the

equipment while the system is operating.

• Make sure all connections are securely tightened

before using this equipment.

• Always read and follow the fluid manufacturer’s

recommendations regarding fluid compatibility,

and the use of protective clothing and

equipment.

• Check all equipment regularly and repair or

replace worn or damaged parts immediately.

• Never place your hand on or near the pump

suction inlet.