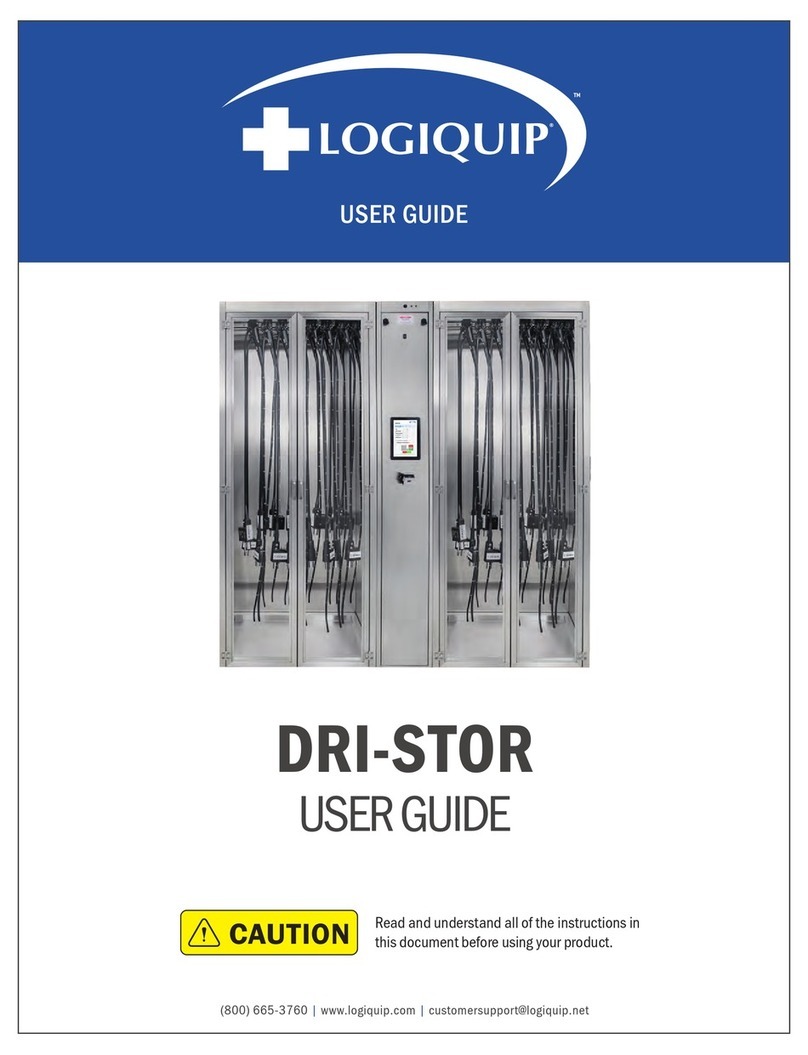

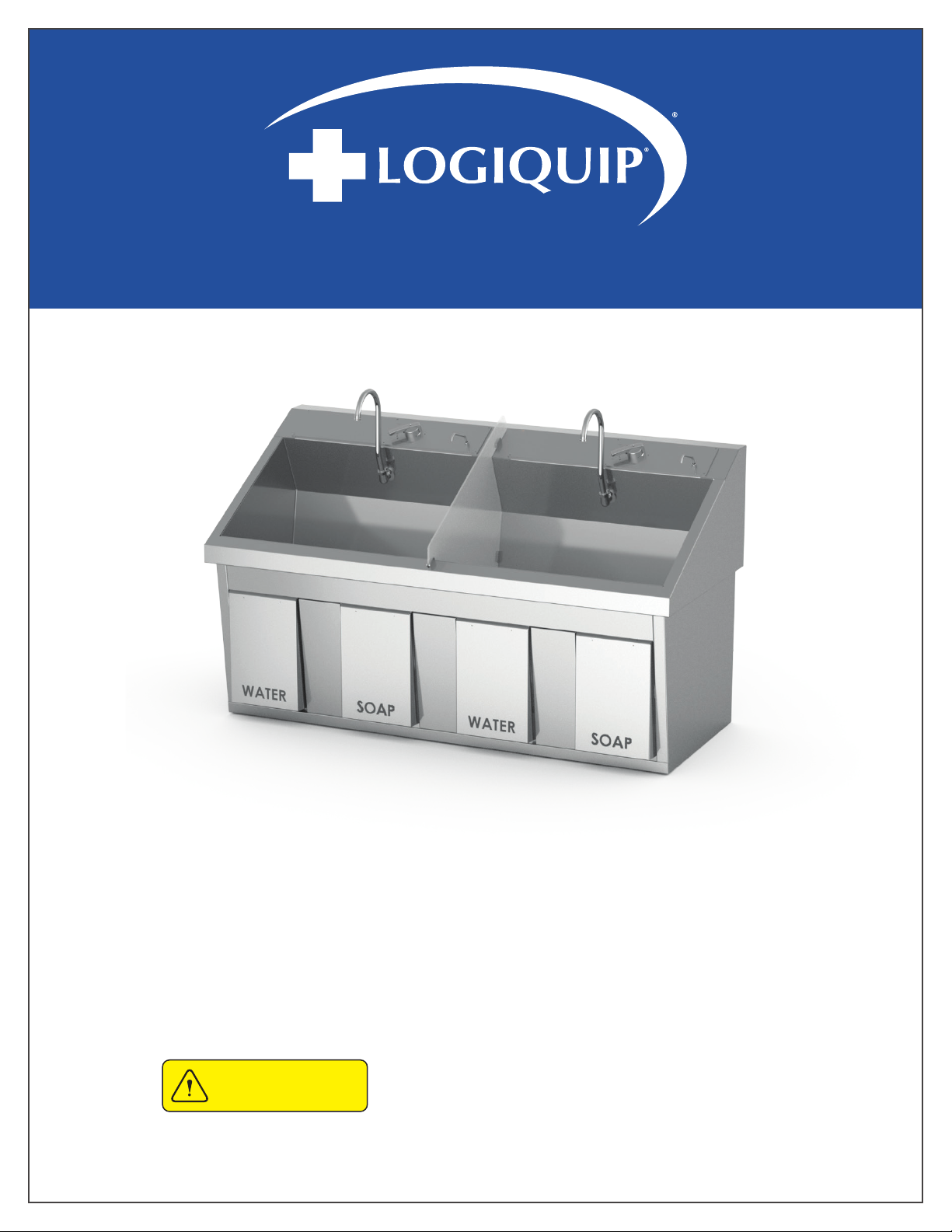

SCRUB SINKS USE & INSTALLATION GUIDE

(800) 665-3760

6|

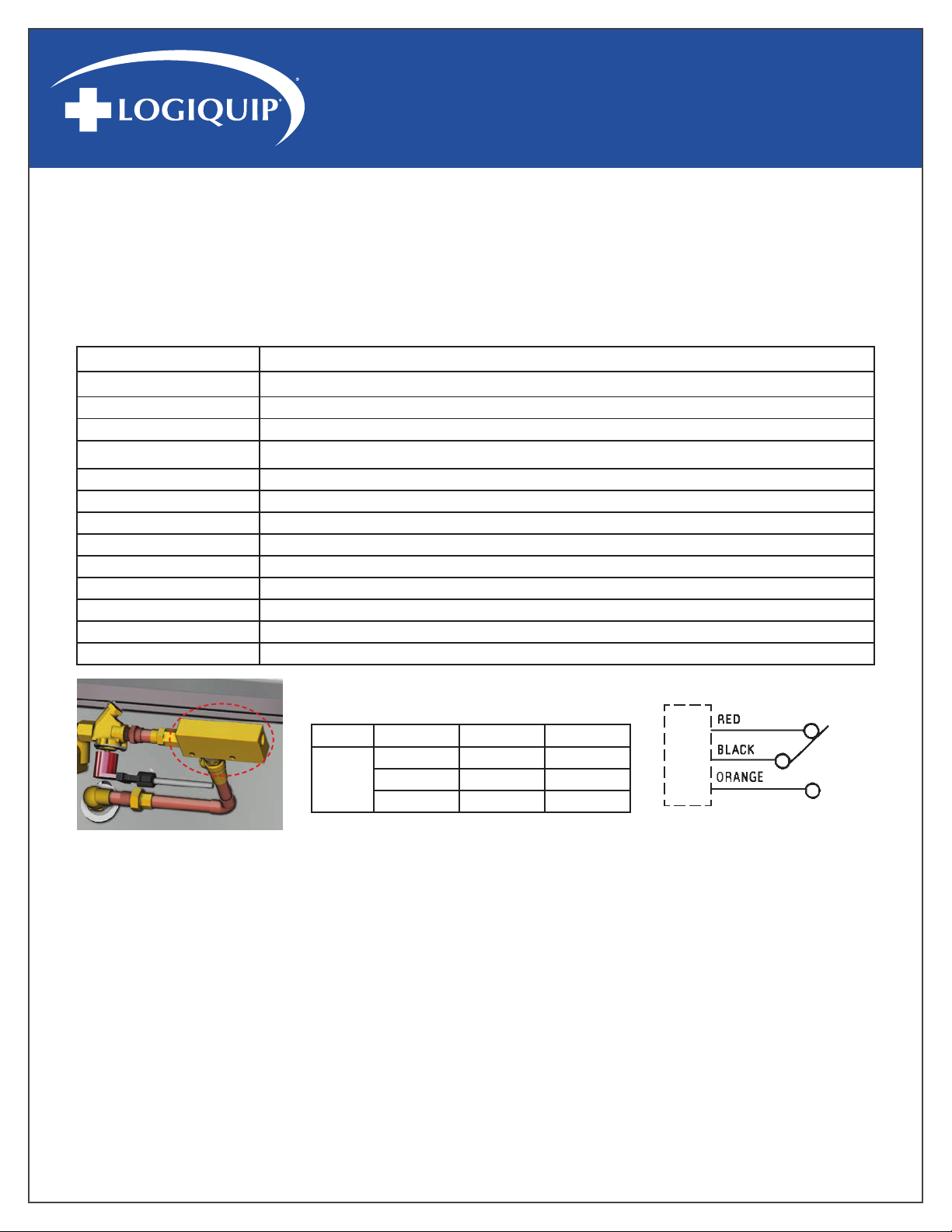

IN-LINE FLOW SWITCH TIMER CONTROLLER (S0130-01) – SPECIFICATIONS, SWITCH RATING

AND WIRING DIAGRAM

NOTE: This feature (Fig. 1) is available only on Infrared Activated Scrub Sinks.

This is an explosion-proof brass flow switch, actuation setpoint 0.50 GPM (1.89 LPM), and calibrated for water at standard conditions. It

is used for the accurate detection of excessive or insufficient flow rates.

This unit was calibrated in a vertical position, with lead wires up. Install the unit in the piping system, using standard pipe fitting

procedures. Be sure to keep thread sealing compound out of unit. Make sure that flow is in the proper direction - marked “IN” and

“OUT” on housing. See wiring diagrams for electrical connections.

CAUTION: See “Switch Ratings” before connecting power.

CAUTION: Flow settings for this switch is normally calibrated using water @ +70°F on increasing flow. Water-calibrated units are not

recommended for air/gas applications.

SWITCH TIMER CONTROLLER MAINTENANCE

Accumulation of foreign debris should periodically be removed from these switches. Occasional “wipe-down” cleaning when excessive

contamination is present is all that is normally required.

TO CLEAN: Remove unit from system and disassemble as shown below. Clean all parts, reassemble and reinstall unit.

NOTE: 50 micron filtration is recommended.

Fig. 1 – In-Line Flow Timer Controller

Service Compatible liquids

Wetted materials Housing: brass; Piston: polysulfone; Spring: 316SS; O-Ring: Fluoroelastomer, Other: Epoxy.

Temperature Limits -20 to 225°F (-29 to 107°C).

Pressure Limits 1000 psig (68.9 bar).

Accuracy ±10% of set point.

Repeatability ±1%.

Switch Type* SPDT, 20 VA

Electrical Rating .17 A @ 120 VAC, .08 A @ 240 VAC, .13 A @ 120 VDC, .06 A @ 240 VDC.

Electrical Connection 18 AWG, 24" (60.96 cm), Polymeric lead wires.

Process Connection 1/4" female NPT.

Mounting Orientation Any position. Set points shown are based on vertical, inlet down position.

Required Filtration 50 microns or better.

Weight 0.66 lb (301 g).

Agency Approval CE

*Switch Ratings Max Resistive Load

VA Volts Amps AC Amps DC

20

0-30 .4 .3

120 .17 .13

240 .08 .06

AA

CC

BB

Pin Connections for Units with

MS Receptacle

TTyyppiiccaall WWiirriinngg DDiiaaggrraamm

Piston

Inlet Fitting

Housing

Spring

O-Ring

Service Compatible liquids

Wetted materials Housing: brass; Piston: polysulfone; Spring: 316SS; O-Ring: Fluoroelastomer, Other: Epoxy.

Temperature Limits -20 to 225°F (-29 to 107°C).

Pressure Limits 1000 psig (68.9 bar).

Accuracy ±10% of set point.

Repeatability ±1%.

Switch Type* SPDT, 20 VA

Electrical Rating .17 A @ 120 VAC, .08 A @ 240 VAC, .13 A @ 120 VDC, .06 A @ 240 VDC.

Electrical Connection 18 AWG, 24" (60.96 cm), Polymeric lead wires.

Process Connection 1/4" female NPT.

Mounting Orientation Any position. Set points shown are based on vertical, inlet down position.

Required Filtration 50 microns or better.

Weight 0.66 lb (301 g).

Agency Approval CE

*Switch Ratings Max Resistive Load

VA Volts Amps AC Amps DC

20

0-30 .4 .3

120 .17 .13

240 .08 .06

A

C

B

Pin Connections for Units with

MS Receptacle

TTyyppiiccaall WWiirriinngg DDiiaaggrraamm

Piston

Inlet Fitting

Housing

Spring

O-Ring

Service Compatible liquids

Wetted materials Housing: brass; Piston: polysulfone; Spring: 316SS; O-Ring: Fluoroelastomer, Other: Epoxy.

Temperature Limits -20 to 225°F (-29 to 107°C).

Pressure Limits 1000 psig (68.9 bar).

Accuracy ±10% of set point.

Repeatability ±1%.

Switch Type* SPDT, 20 VA

Electrical Rating .17 A @ 120 VAC, .08 A @ 240 VAC, .13 A @ 120 VDC, .06 A @ 240 VDC.

Electrical Connection 18 AWG, 24" (60.96 cm), Polymeric lead wires.

Process Connection 1/4" female NPT.

Mounting Orientation Any position. Set points shown are based on vertical, inlet down position.

Required Filtration 50 microns or better.

Weight 0.66 lb (301 g).

Agency Approval CE

*Switch Ratings Max Resistive Load

VA Volts Amps AC Amps DC

20

0-30 .4 .3

120 .17 .13

240 .08 .06

AA

CC

BB

Pin Connections for Units with

MS Receptacle

TTyyppiiccaall WWiirriinngg DDiiaaggrraamm

Piston

Inlet Fitting

Housing

Spring

O-Ring

*Switch Ratings Max Resistive Load