13/05/2020

LFU-T1000*-*-DF-O-12

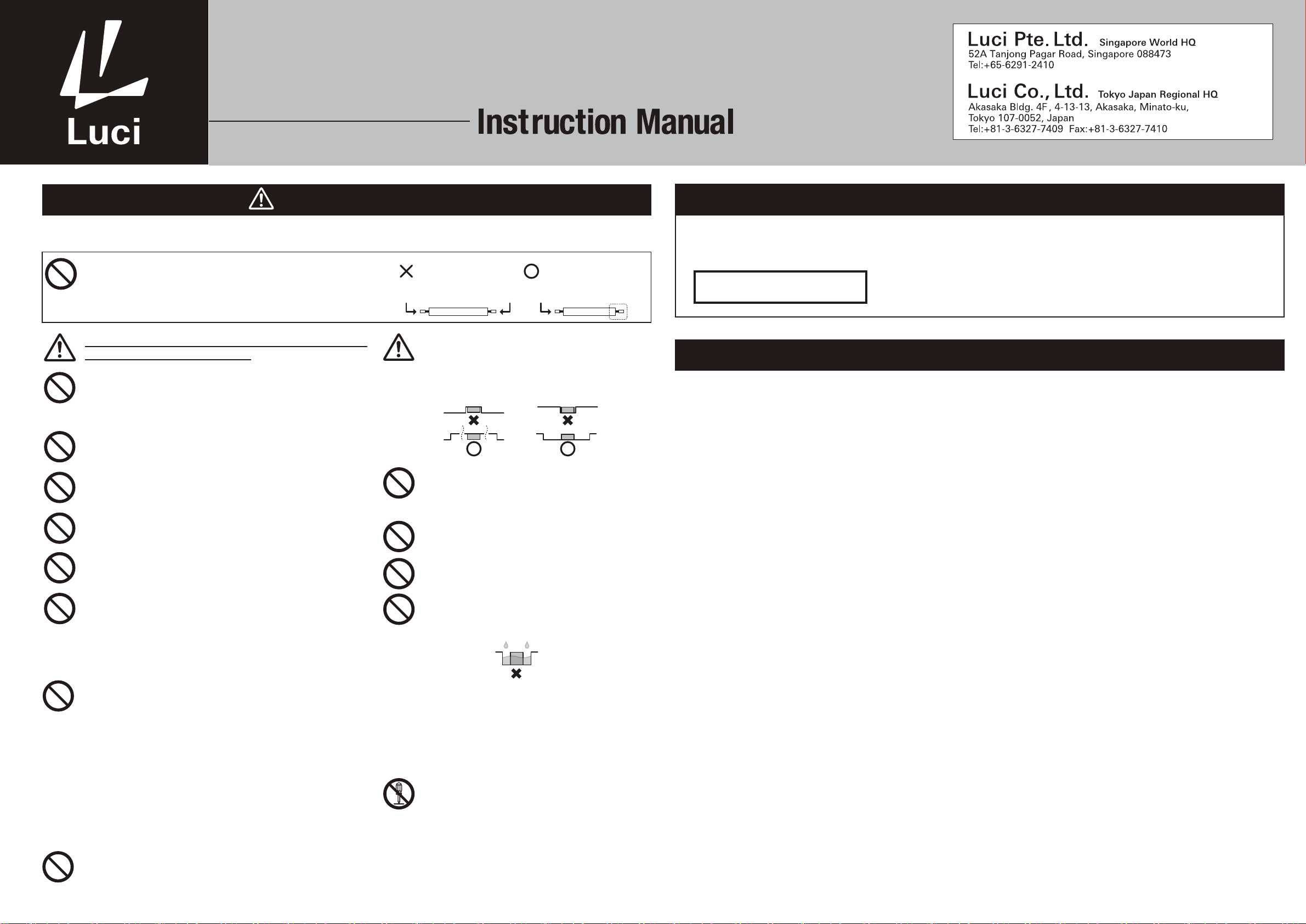

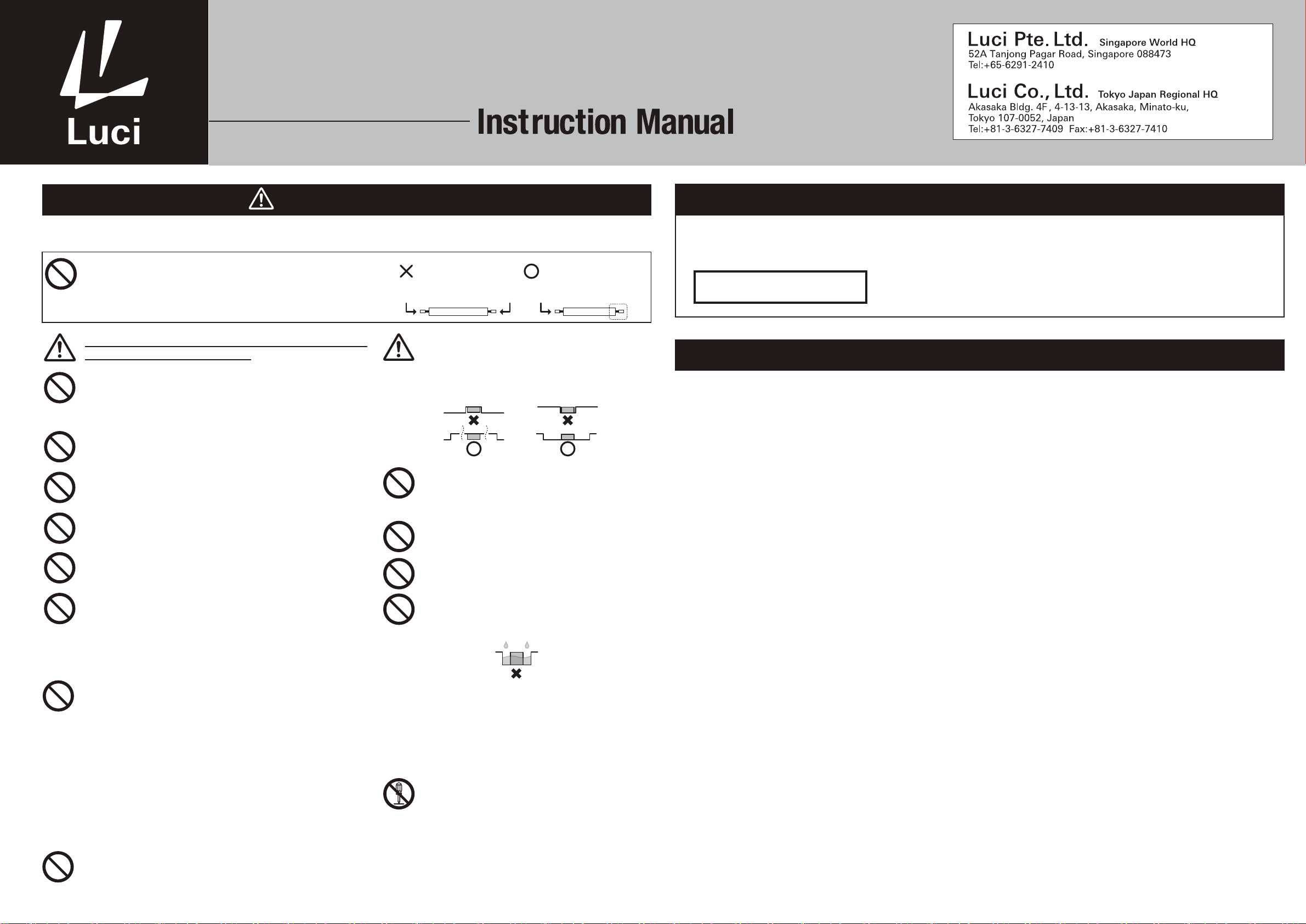

Only supply power through the lead wire on one side

using the dedicated connection cable for this product.

Supplying power through the lead wires on both sides may cause failure and fire. DC24V DC24V

Do not supply the power

through the lead wire from

both sides.

Supply the power through the

lead wire from one side.

DC24V Attach the

connector cap

To ensure safe usage

The following is the safety cautions to prevent any harms or damages to others.

If the product is used against cautions, it may cause damages・electrifications・smoke.

Please read before the usage

Caution regarding installation

environment of power supply

Regarding the temperature, humidity, and other conditions of the operating

environment, follow the instructions in the manual for the power supply.

●The product has been manufactured with the utmost care; however, please understand that slight deviations in LED color are unavoidable due to the

●To mount in the mounting position, use mounting clips (Accessories) and confirm that the mounting clip is securely fixed.

characteristics of the product.

Maintenance and Inspection

・LED fixture has a life span.

・Degradation occurs inside after a few years of installation even when the fixture looks fine from the outside.

Parts of the LED fixture degrade due to heat when the light is on for a long time. This causes not only

safety issues, but also reduces power efficiency and it is recommended to have regular maintenance and inspection.

・Cleaning and inspection should be performed at least once every 6 months.

・Inspection by a specialist, such as a product contractor, should be performed at least once every 2 years.

・If the LED fixture is used for a long time without having an inspection, there is a small possibility that it could lead to

fuming, igniting, electric shock and the like.

Inspection Methods

・Is LED operating normally?

・Is there any unusual smell, sound or heat?

・Are there any cracks, splits, or detached parts on any parts or joints?

Cleaning Method

・Lightly wipe the LED fixture with a soft cloth.

・To best clean the LED fixture, wipe dirt with a soft cloth which has been soaked in a neutral detergent diluted with

water and wrung firmly. To finish off, wipe it with a damp cloth and dry it.

Use a DC24 V power supply. Never connect to any other power supply.

Always use a Overcurrent breaker / circuit breaker of suitable capacity

in the power supply.

If the capacity is not suitable, the breaker may not workwhen

abnormal current occurs, creating risk of fire.

Always shut off the main power supply before performing work or inspection.

Do not connect ordisconnect the lead wires of the LED fixture while power is supplied.

Firmly insert and connect the connectors.

Incomplete connection may cause heating, smoke, and fire.

Do not touch the ends of the connectors. Risk of electrical shock.

When there is abnormal situations, please cut off the power immediately, consult

with electricians, and do not touch the LED fixture with hands.

The product must be allowed to dissipate heat.

Risk of shortened service life and fire.

Allow sufficient space for ventilation (heat dissipation) between

the LED fixture and building structure.

When installing the LED fixture in a box, please make sure to

provide the air ventilation hole.

Always test before connecting the LED fixture to a switch ordimmer.

Do not use the product if the cover is damaged.

Risk of an accident and electrical shock.

Avoid spraying detergent directly on the LED fixture.

If this happens, immediately rinse with water.

Do not use a brush or an abrasive to polish metal parts.

Risk of damage and corrosion.

Do not use in the following environments:

- A location where water collects,and under the water.

- A location at high temperature (+45°C or higher)

(usage environment temperature is -25°C to+45°C)

- A location with corrosive or inflammable gases.

- A highly airtight location.

- A location where the product is directly exposed to salt water or

organic solvents.

- A location subject to the effects of electric or magnetic fields.

- A location subject to intense vibration or shock, or a location subject

to continuous vibration.

Do not do the following to the LED fixture:

- Forcibly remove the product after mounting it.

- Disassemble, modify, or add holes to the product.

- Forcibly pull or twist the product.

- Cut or damage the power cable. Use a damaged cable.

- Press down on the product.

- Drop the product or subject the product to intense vibration or shock.

If the product is dirty, wipe with a dry cloth.

Do not use thinner, benzene, or other organic solvents to clean

the product, and do not wash with water.

Do not place a heatable object such as a cloth or paper or an insulating material

on top of the LED fixture or cover it with such a material. It may cause the

fixture not to turn on or fire.

Do not put a piece of metal or a flammable object in clearance of the LED fixture.

The outline of the LED fixture main unit must not contact equipment in or

out of the ceiling. It may cause fall, electric shock, or fire.

Do not operate the fixture with wet hands. It may result in an electric shock.

Electrical work certificate is needed to install and inspect this product.

Please ask electrician for the installation.

Important notice for storage

Observe the storing temperature of our LED fixtures: -35°Cto 65°C

Please do not store the carton or the packages of our LED fixtures in the following

conditions:

- wet location

- places of high humidity

- places with much litter or dust

- places of exposing against sun light directly

- places a solvent such as a paint liquid is stored

During storing period, please do not leave the cartons orindividual packages vertically.

Please do not open individual package until just before installing LED fixtures to

avoid any damage to the LED fixtures.

Please do not place heavy object on the carton.

Please do not use our LED fixtures as the working light during construction period.

Luci UQ FLEX IP67