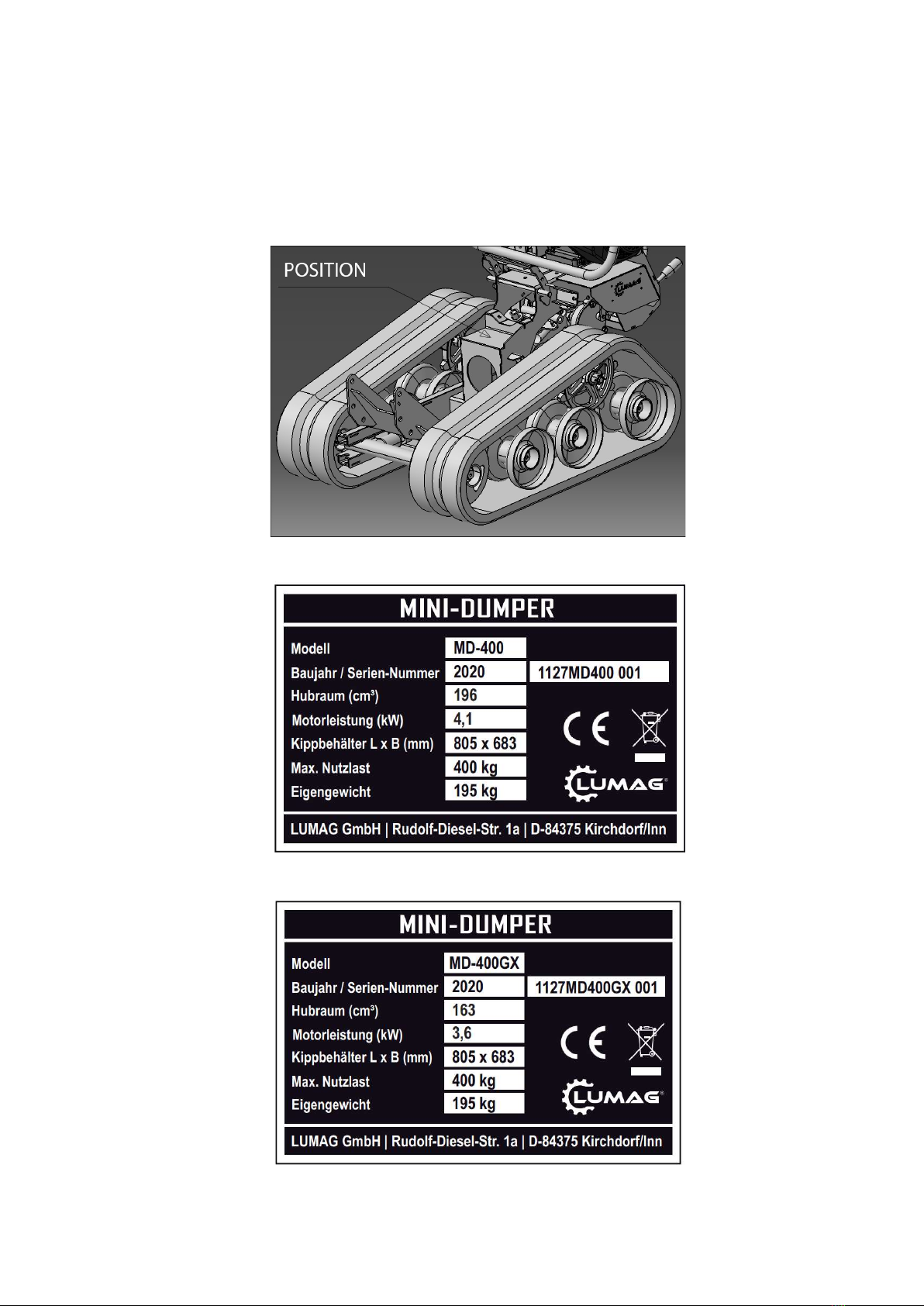

LUMAG GmbH MINI TRANSPORTER MD400 MD400GX

OPERATING AND MAINTENANCE INSTRUCTIONS Sheet 4 of 22

1. Safety instructions

This machine is intended for carrying grains, produce, dirt and similar materials. Carrying other objects may

damage machine. Avoid carrying liquid concrete. That will damage machine. The stability of machine is

affected by speed, rate of steering, terrain and load. Always pay close attention to these factors or loss of

control or tipping over could occur, resulting in property damage, serious injury or death.

1.1 General Driving

• Do not operate engine in a confined space where dangerous carbon monoxide fumes can accumulate.

• Do not touch engine, muffler or exhaust pipe while engine is running or soon after it has stopped. These

areas will be very hot and can cause burns.

• Do not operate machine under the influence of alcohol or drugs. Do not operate machine when you are

tired, ill, or not fit to operate machine.

• Before starting engine and moving machine, scan around your surroundings and make sure all persons

and other vehicles are a safe distance away from machine.

• Never operate on terrain that you are not comfortable with. Avoid terrain that is so rough, slippery or loose

that you feel like you could tip over.

• Always check for obstacles before operating on new terrain. Travel slowly and use extra caution when

operating on unfamiliar terrain. Be alert when traveling on changing terrain.

• Always hold handle grips with both hands to keep a posture when operating machine.

• Drive at a safe speed, taking into account surface gradient, surface conditions and load.

• Do not make sudden maneuvers. Sudden start, stop, or turn can make machine lose control and could

cause a tip over. Be especially cautious when traveling on soft or wet ground.

• On a slippery surface, travel slowly and exercise caution to reduce the chance of skidding or sliding out

of control. Never operate on ice.

• Always make certain that there is no obstacle or person behind machine when backing up. Make certain

that it is safe to back up, then move slowly and avoid sharp turns.

• To reduce the risk of tipping over, pay special attention when encountering an obstacle or a slope, or when

braking on a slope or during a turn. See Driving on a Slope below.

• Never attempt to drive over a large obstacle such as rock or fallen tree.

• Do not operate machine near the edge of a cliff, an overhang or a landslide area.

• Use an observer to help direct machine when visibility is poor, terrain is rugged or hilly, or maneuvering

room is limited. An observer should be able to see machine and its immediate surroundings, and should

give pre-arranged signals to direct the operator.