1

Contents

1.

1.1

1.2 Liability Exclusion................................................................................................................................................................2

3.

3.1 The dimensions of MT1050/1550-EU/MT1050-RS485 ................................................................................4

3.2 The dimensions of MT2075/2010/3075...............................................................................................................5

3.3 The dimensions of MT3010/4010............................................................................................................................6

3.4 The dimensions of MT4015 ........................................................................................................................................7

4.

4.1 Characteristics of MT1050/1550-EU/MT1050-RS485........................................................8

4.2 Characteristics of MT2075/2010/3075.......................................................................................8

4. Characteristics of MT 010/4010/4015.......................................................................................9

4.4 Temperature Sensor .......................................................................................................................................................9

4.5 RS485 .....................................................................................................................................................................................10

4.6 Optional Accessories.....................................................................................................................................................10

5.

5.1 Installation Notes............................................................................................................................................................12

5.2 Mounting Location Requirements..........................................................................................................................12

5.3 Wiring Specifications ....................................................................................................................................................13

5.4 Connection .........................................................................................................................................................................13

5.5 Grounding ...........................................................................................................................................................................14

6.Operation ...................................................................................................................................................15

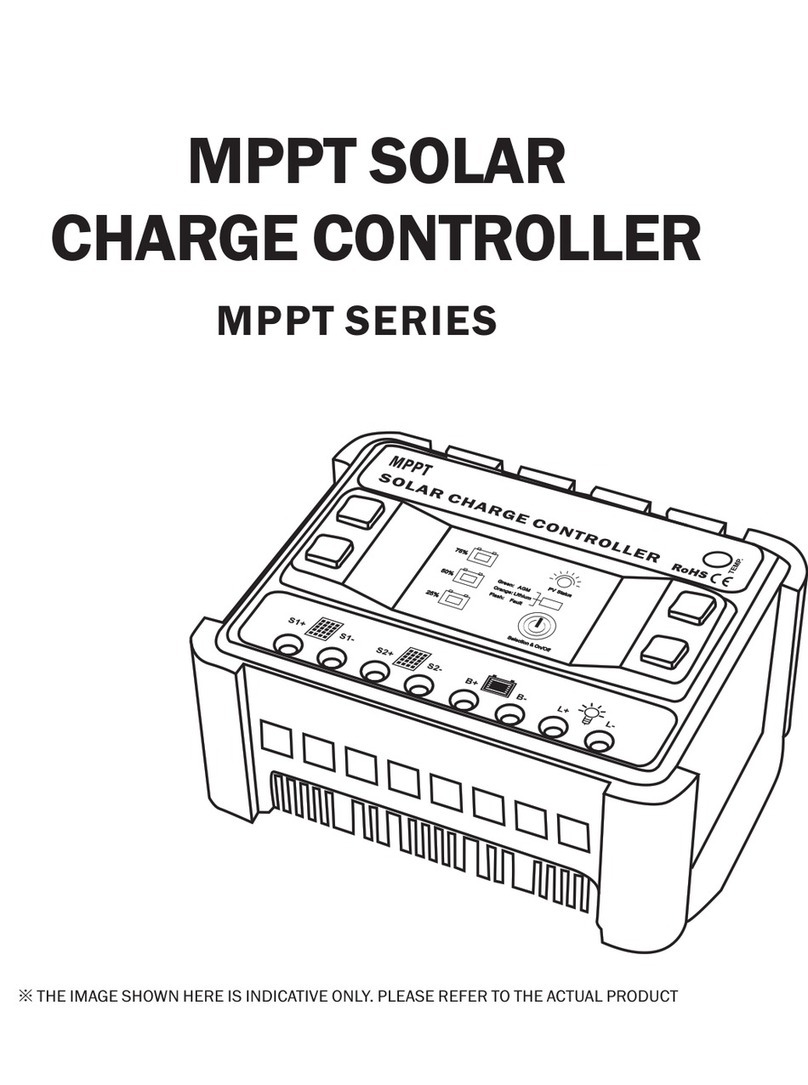

6.1 LCD Display.........................................................................................................................................................................15

6.2 Key function .......................................................................................................................................................................17

6.3 USB interface .....................................................................................................................................................................17

6.4 Parameters setting..........................................................................................................................................................18

7.Protections, Troubleshooting and Maintenance ............................................................................20

7.1 Troubleshooting ..............................................................................................................................................................20

7.2 Protection............................................................................................................................................................................21

7.3 Maintenance ......................................................................................................................................................................21

Safety instructions and waiver of liability...............................................................................................2

Safety Instructions ..............................................................................................................................................................2

Pruduct Overview .......................................................................................................................................3

Dimensions ................................................................................................................................................4

Structure & Accessory ............................................................................................................................8

Structure &

Structure &

3 Structure & 3

Installation.................................................................................................................................................12

8.Technical Data .............................................................................................................................................22

2.

1