SY 220 / SY 250 Light Module Installation Instructions

www.Lumishore.com

Lumishore UK Unit 2, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34243 |(941) 405-3302 | Sales@LumishoreUSA.com

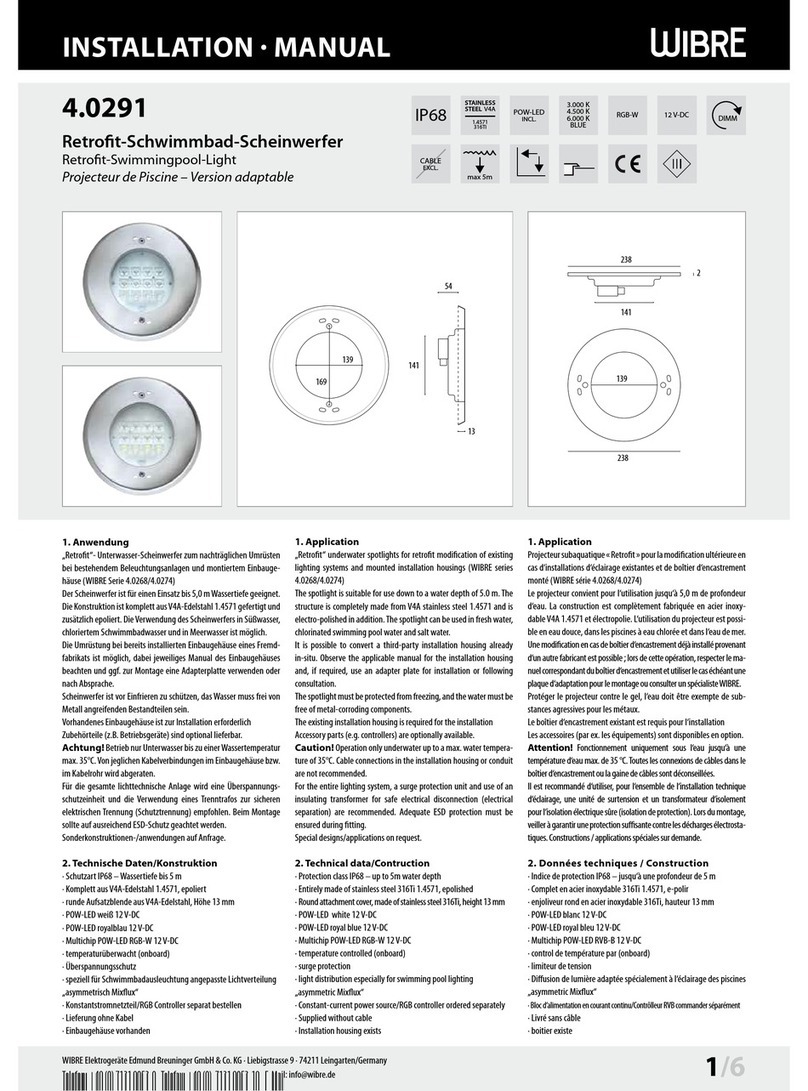

LIGHT MODULE INSTALLATION

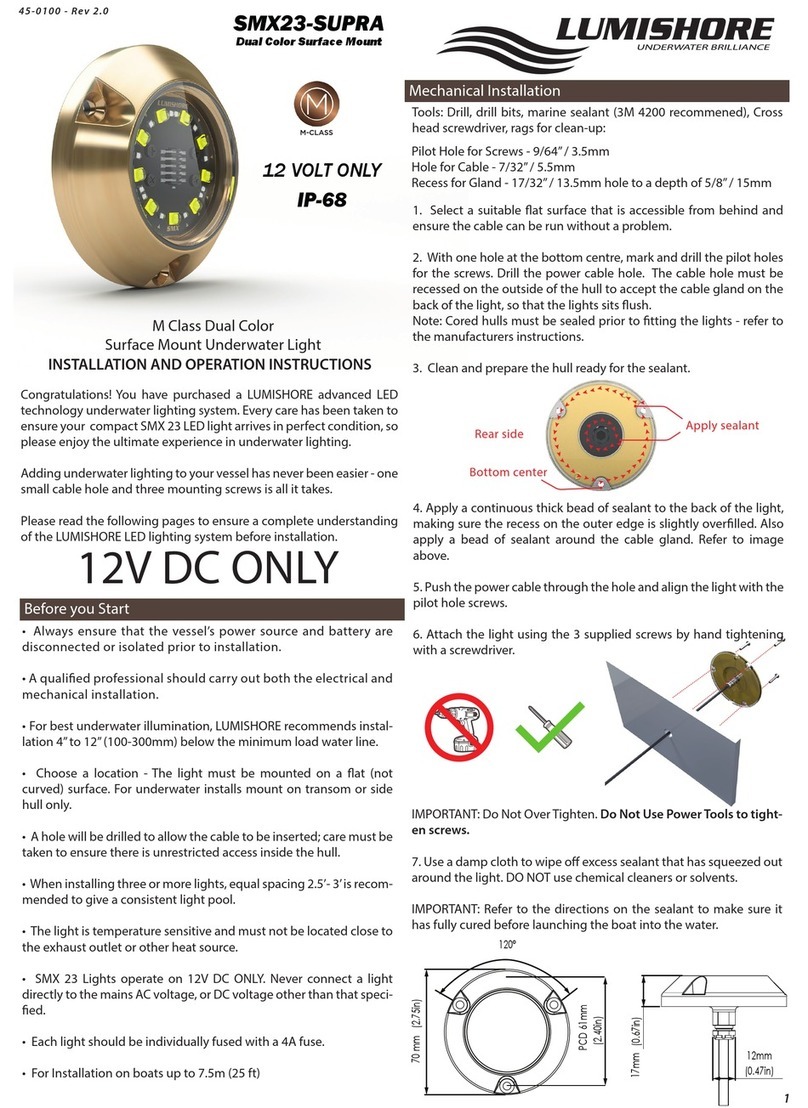

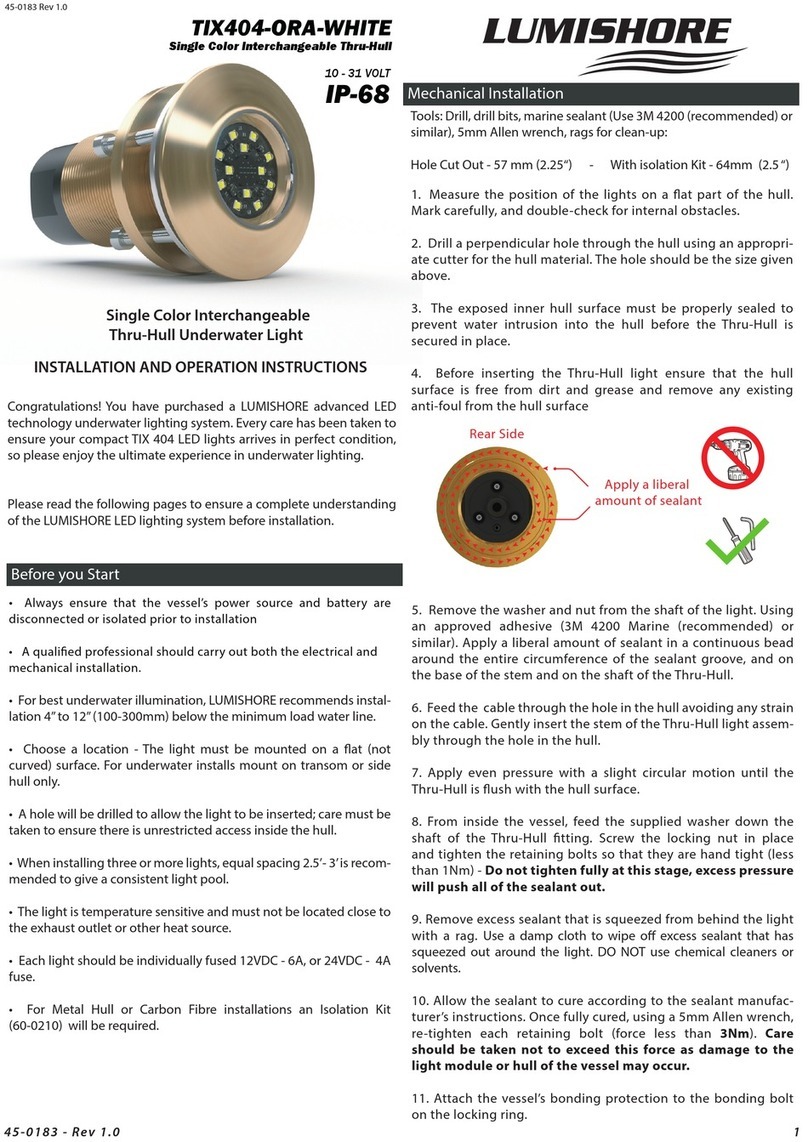

1) Check that the lens has been tted and tested following the procedure 45-0075. Remove the ange cover plate.

2) Clean the weld-in ange thoroughly with IPA, and a CLEAN rag. Check the ange for any damage, debris or weld splatter. The gasket mating

surfaces must be clean and at before the light can be tted.

3) There are two dierent light beam angles for each of the SY 220, and SY 250. These are 60 Degree, and 100 Degree. The 100 Degree light has a

at glass front covering the array, and the 60 Degree light has a convex lens covering the array. CHECK THE BEAM ANGLE IS THE CORRECT ANGLE

FOR THE HULL POSITION before tting.

4) Check the O ring is in place on the light module. Place the light module over the light and align the holes.

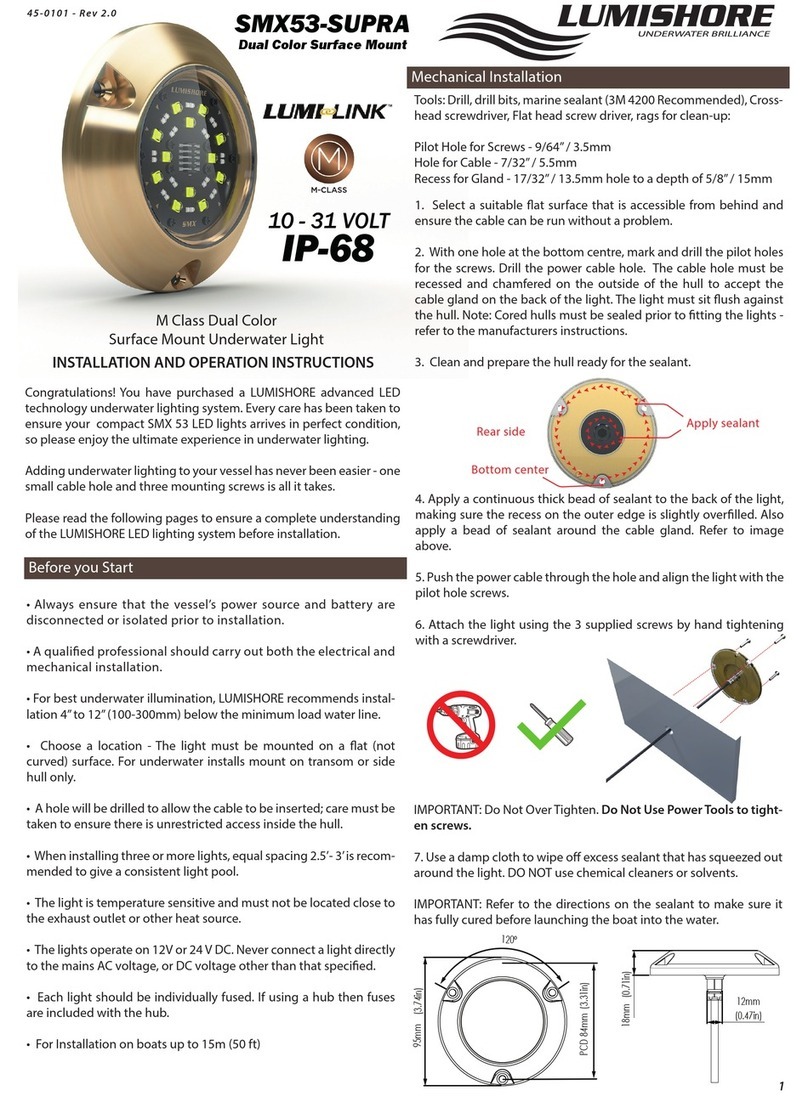

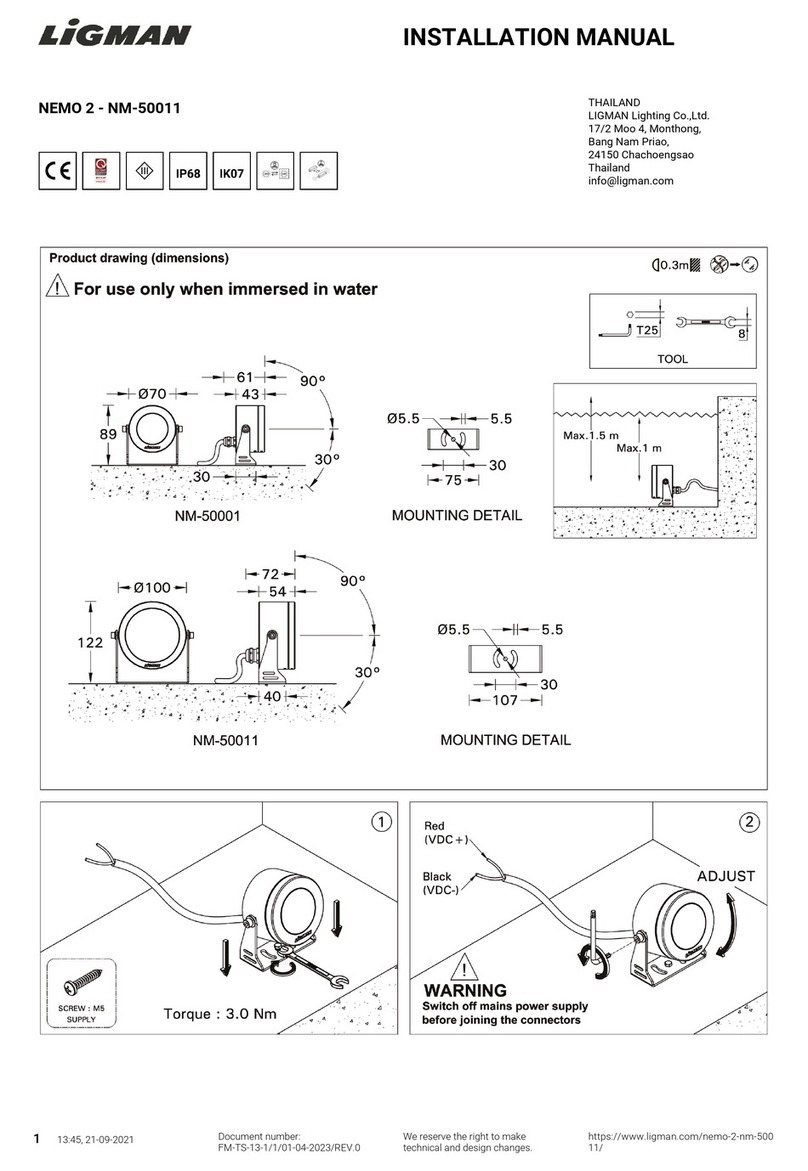

6) Tighten the bolts in a circular pattern (as shown in the diagram). Tighten the bolts half a turn at a time, then move on to the next bolt. USING A

TORQUE WRENCH tighten the bolts to a torque of 15 Nm.

1

4

7

25

3

6Tighten each bolt half a

turn at a time until ALL

bolts are fully torqued

5) Apply a small amount of Loctite 243 (supplied) to the thread of each bolt before tting. Fit the light module to the ange, and secure in place

using the bolts - MAKE SURE that the bolts have the washer and nylon insulating washers tted.

Flange

(already

welded into

the hull with

lens tted)

Light Module Securing bolts,

washers and insulation

washers

APPLY LOCTITE

243 TO THE

THREAD OF

EACH SCREW

2

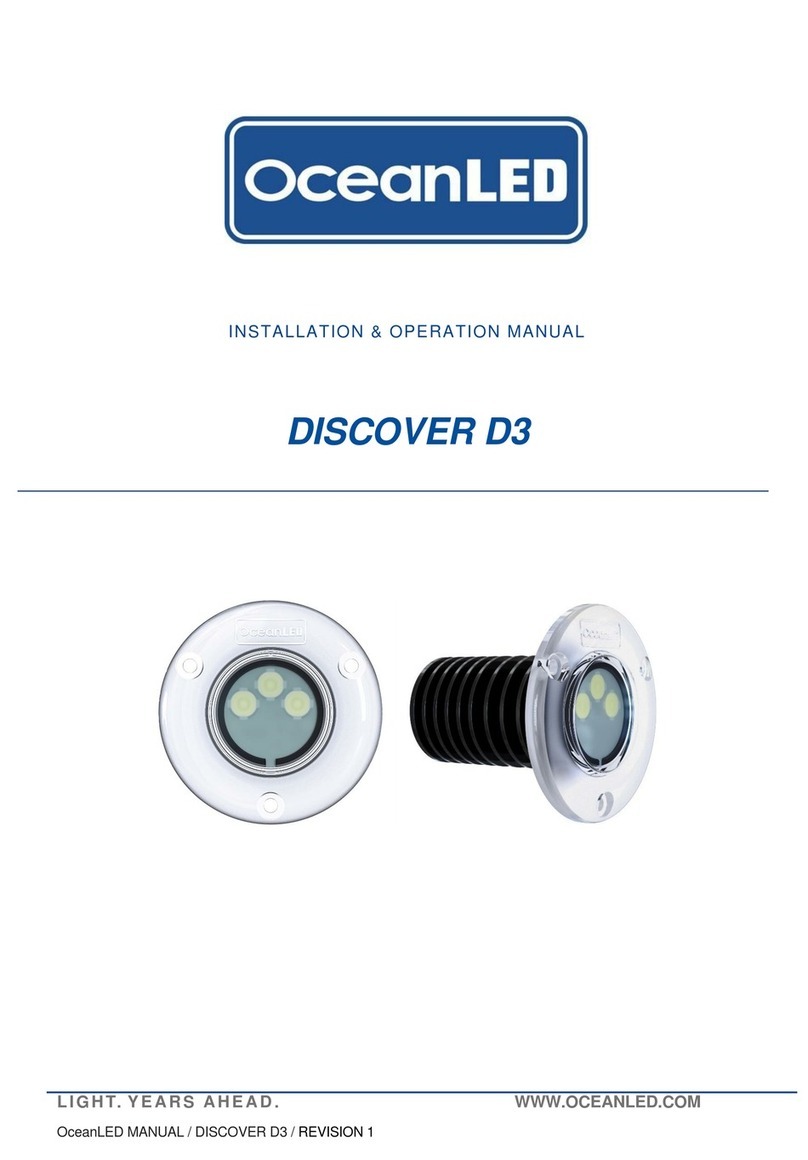

SY 220 / SY 250

60 Degree

Light and

Cable

Note: Cable is detach-

able - leave dust cap

tted until the cable is

ready to be tted)

Rear surface must be clean,

at and dent free