7

www.Lumishore.com

Lumishore UK Unit 2, Technium 1, Kings Road, Swansea, SA1 8PH, UK | +44(0)208 144 1694 | Info@Lumishore.com

Lumishore USA 7137 24TH Court East Sarasota, Florida 34243 |(941) 405-3302 | Sales@LumishoreUSA.com

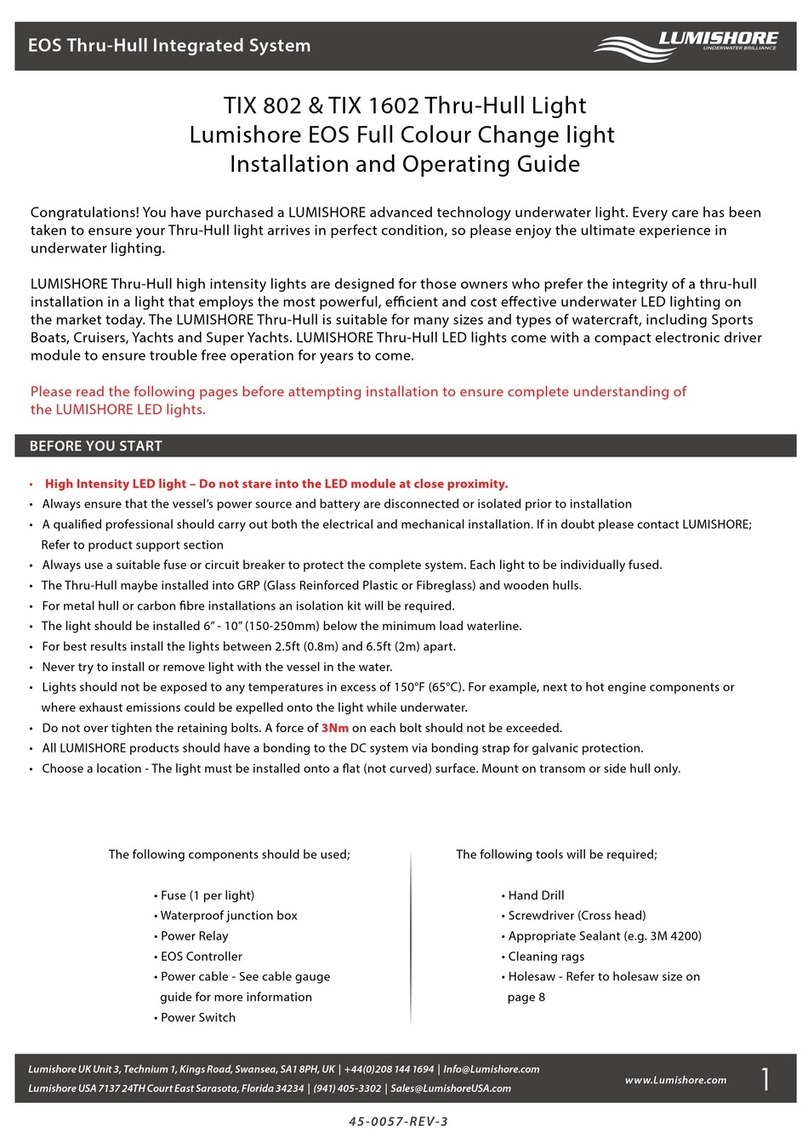

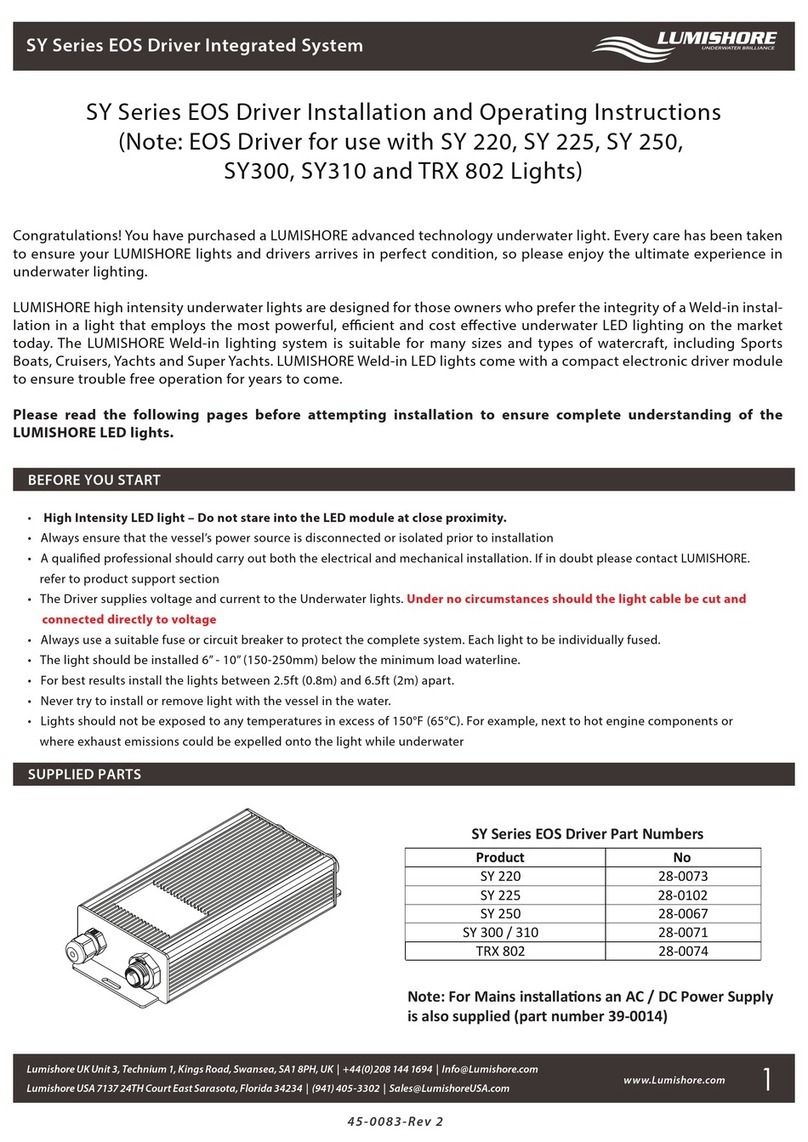

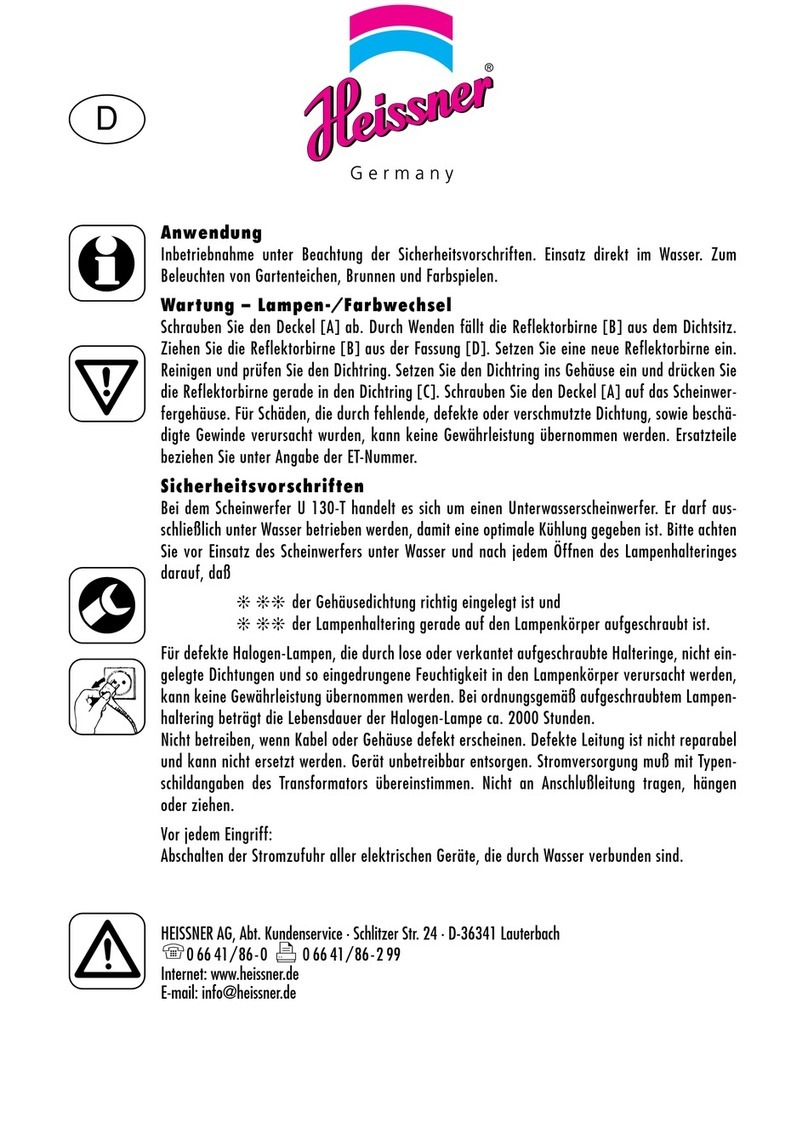

In the event of one or more of the lights not lighting up then check the LED status on the driver (at the back of the light).

The LED will either be continually ON (healthy), OFF (no power to driver) or ashing. Please refer to the table below for

what the number of ashes means and what action to take.

Thank you!

For purchasing LUMISHORE lights

In the event of an issue, record the serial number(s) of the light(s) and contact your local dealer.

Troubleshooting

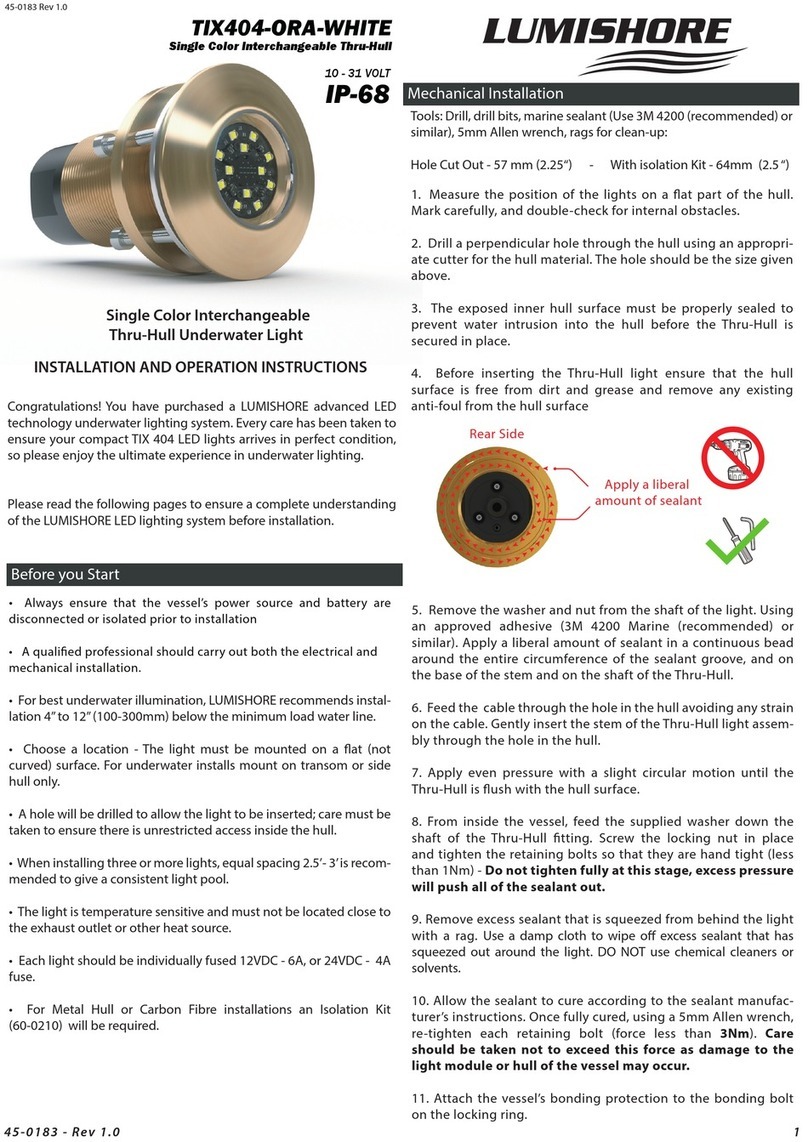

LUMISHORE Ltd warrants the Thru-Hull lighting system to be free from defects in workmanship for a period of three

years, starting from the date of original purchase. Should your lighting system have a problem during this period,

please contact your dealer as soon as you become aware of the defect.

Misuse, abuse, improper installation, neglect, improper shipping, damage caused by disasters (e.g. re, ood and

lightning), installation by unqualied personnel, unauthorized repair or modication will void this warranty.

For the avoidance of confusion and doubt, non compliance with all installation, maintenance and operating

instructions in this document constitute non conformance with warranty terms.

Full warranty details are available at www.lumishore.com.

Warranty

Warranty & Troubleshooting

LED Status

No LED light on driver

Solid LED

Flashing 2 times

Flashing 3 times

Flashing 4 times

Flashing 7 times

Flashing 8 times

Continuous rapid ashing

Light temp too high

Driver temp too high

LED array voltage out of range

Light not detected

Driver program corrupt

Could happen when light is out of water or next

to exhaust

Driver is mounted too close to an engine or exhaust

Check the connections between light and driver

Check light in each colour to determine if all colours

are working

Light is not connected or cable is cut or pinched

Light has been connected incorrectly to the driver

Reset driver by switching o power for 1 minute, and

then switching on again

Contact LUMISHORE if problem persists

Meaning

No power to driver

Power On

Low input voltage to driver

Action to take / Things to check

Check fuse / breaker

Check connections

Check voltage at input to driver connections

Driver is receiving voltage and operating properly

Check the switch is operating correctly

Check power connections or battery voltage

If a light does not switch on, or function normally, it should be disconnected from the power source

8