BW437-RTU-LX Quick

Guide Contents

www.lynxspring.com

Disclaimers……………………………………………….

Symbol's definition………………………………………...

Contents…………………….……………………………

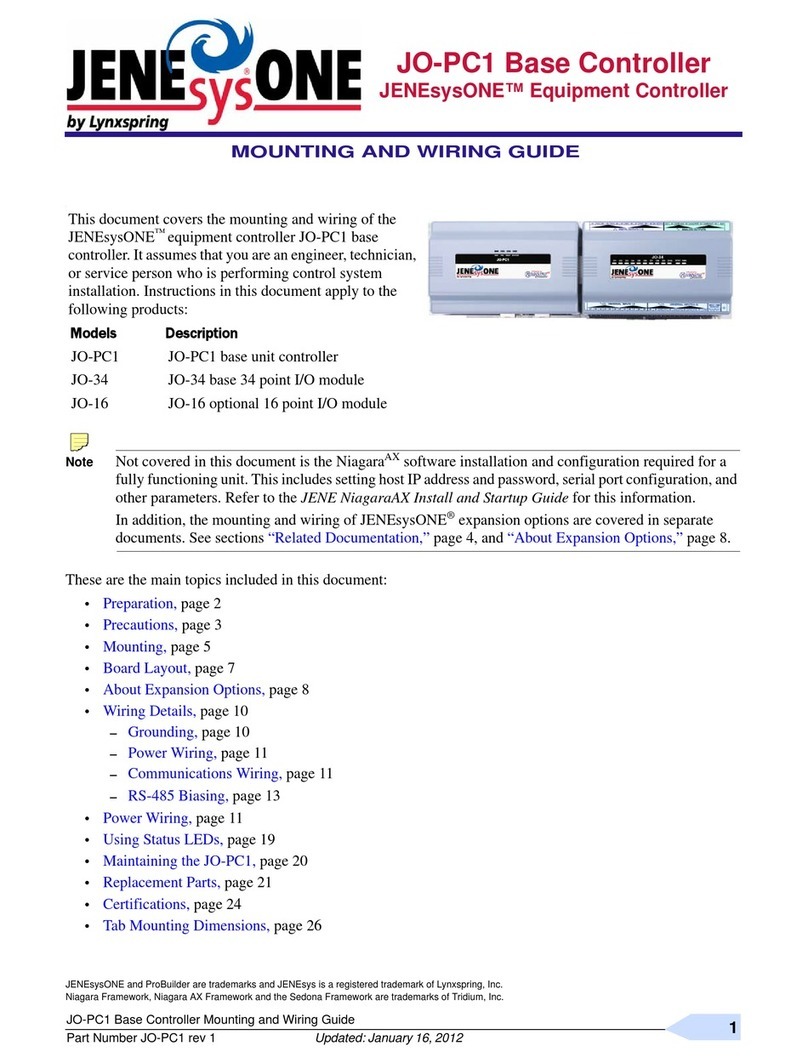

Description and model numbers……………………………

Installation…………………………………………………

Mounting………………………………….………….

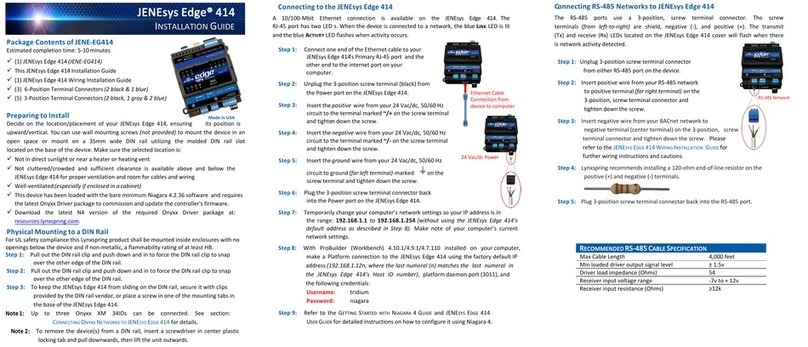

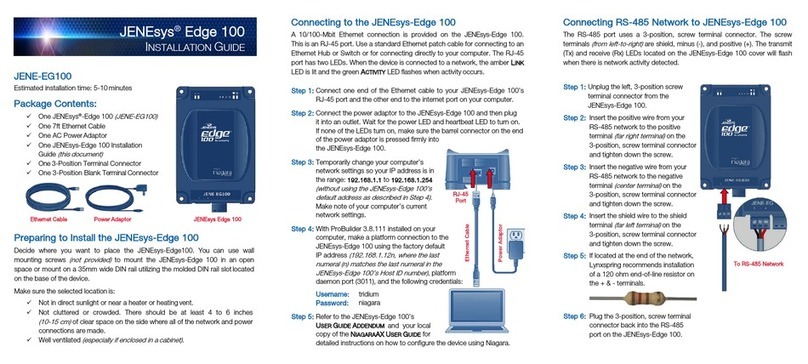

Internal Jumper Settings………………….………….…

Power Supply Connections…………………..…………

I/O’s Wiring Instructions………………..………………

Interface……………………….…………….……………

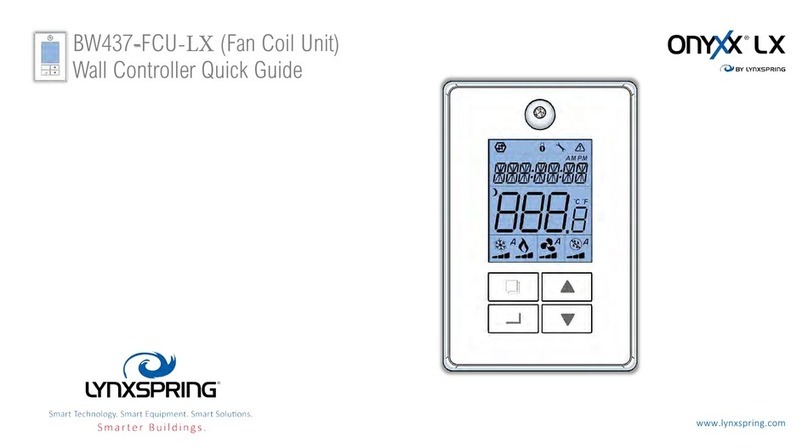

Buttons……………………………………………….

Local LCD display………………………………………

Display Messages on Local LCD display……………………

Cooling and Heating Stages Application note……………………

Using the menus……………………………………..…….

Network configuration settings…………………………..

Quick setup menu………………………………………

p. 2

p. 3

p. 4

p. 5

p. 6

p. 7

p. 8

p. 9

p. 10

p. 12

p. 12

p. 13

p. 14

p. 15

p. 16

p. 16

p. 17

Applications, sequences and curves………………………….

RT 2STG –RTU -2 Stage Heat / 2 Stage Cool……………..

RT ECON –RTU - 2 Stage Heat / 2 Stage Cool with Modulating

Economizer ……………….…………………………….

HP 2STG –Heatpump - 2 Stage Compressor / Reversing Valve

with Modulating Economizer ……………………..………

RT IAQ -RTU -2 Stage Heat / 2 Stage Cool with Modulating

Economizer and CO2…………………………….………

RT MOD –RTU -1 Stage Heat / 2 Stage Cool with Modulating

Heat……………………………………………………

HP DEH –Heatpump –2 Stage Compressor/Reversing Valve

with Staged Dehumidification……………………………

HUM-DEH –RTU –2 Stage Heat / 2 Stage Cool, Staged

Dehumidification with Modulating Humidifier………………

HUM-DEH –HP –2 Stage Heat / 2 Stage Cool, Staged

Dehumidification with Modulating Humidifier………………

RT 2STG –RTU -2 Stage Heat / 3 Stage Cool…….……..

RT 2STG –RTU -2 Stage Heat / 4 Stage Cool…………….

Service menu……………………………………………

Test IO menu…………………………………………….

Physical Inputs and Outputs……………………………….

Analog Values………………………………………….

Binary Values…………………………………………….

Multi-State Values……………………………………….

Specifications…………………………………. ………….

p. 20

p. 20

p. 22

p. 25

p. 27

p. 29

p. 31

p. 33

p. 35

p. 33

p. 36

p. 38

p. 40

p. 41

p. 42

p. 43

p. 45

p. 46

RS485 Network Guidelines…………………………………. …p. 58

p. 63