3SINGLE CARPORT

CYCLONIC

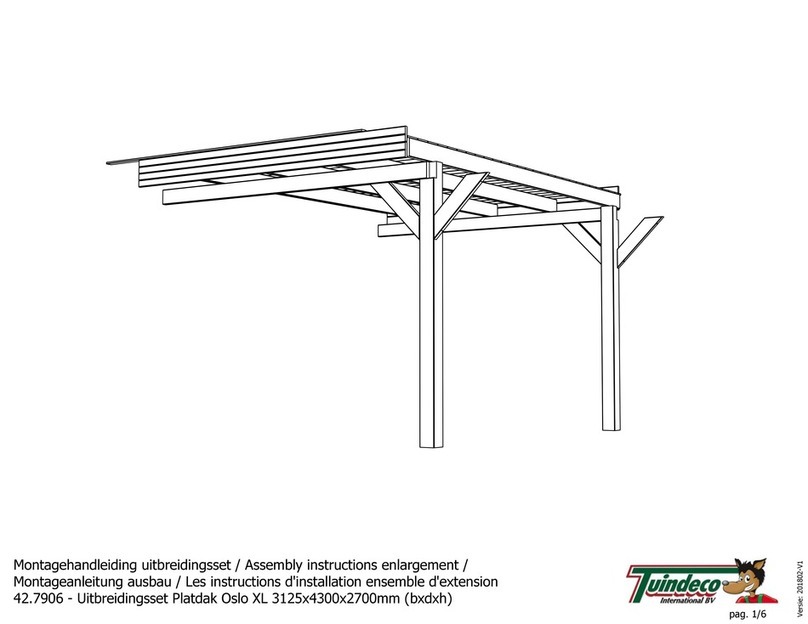

STEP 5 - laying out the beams

Using the drawing, lay the beams close

to the point where they will be assembled.

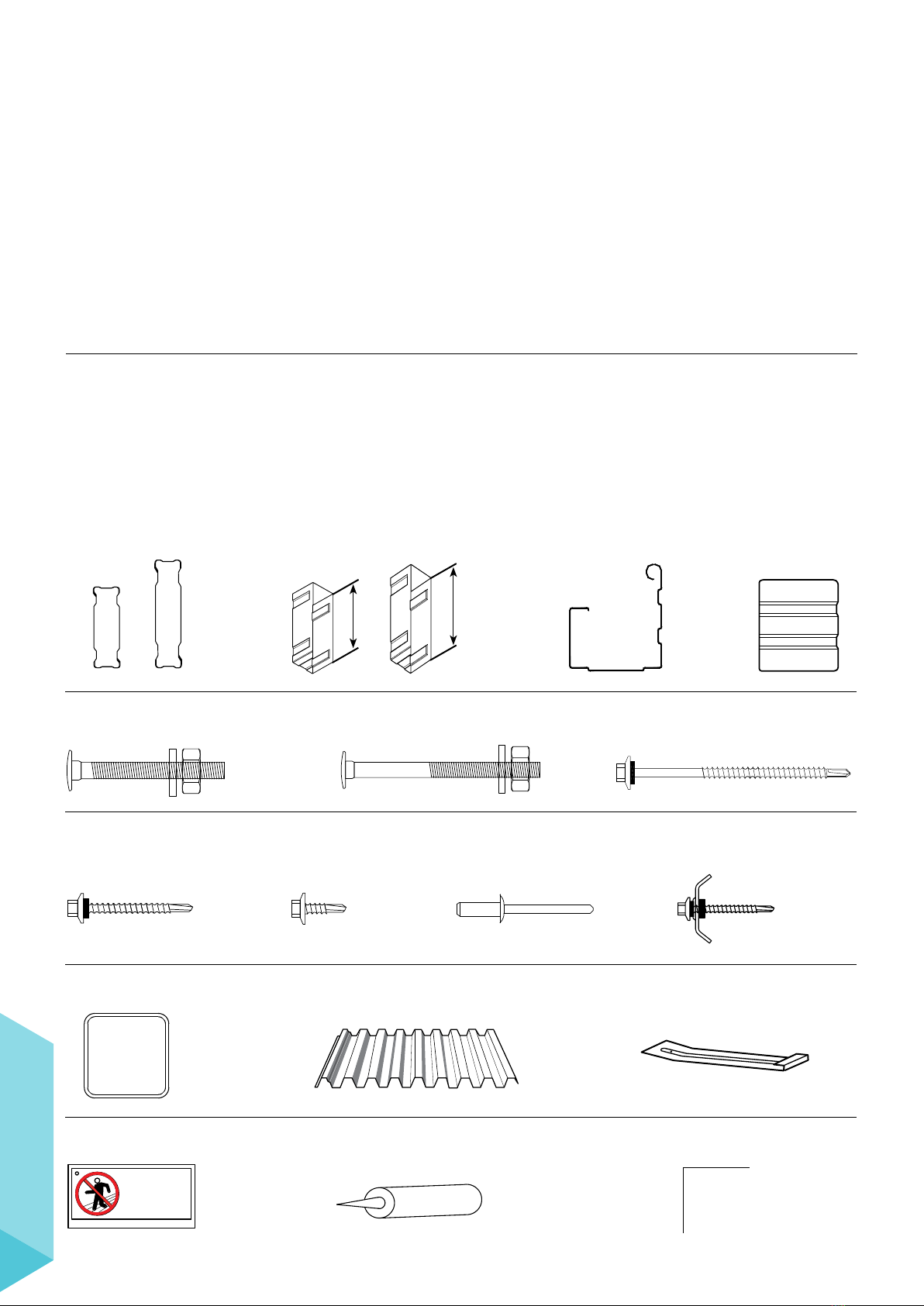

INTERMEDIATE PURLIN

You will have two FIRMLOK®F100

beams that are longer – these are your

intermediate purlins.

HEAD BEAMS

You will have two FIRMLOK®F100 beams

that are shorter in length – these are your

head beams.

RETURN BEAMS

You will have two FIRMLOK®F150 beams –

these are your return beams.

Steel post

Head beam (F100)

Head beam (F100)

Intermediate purlins (F100)

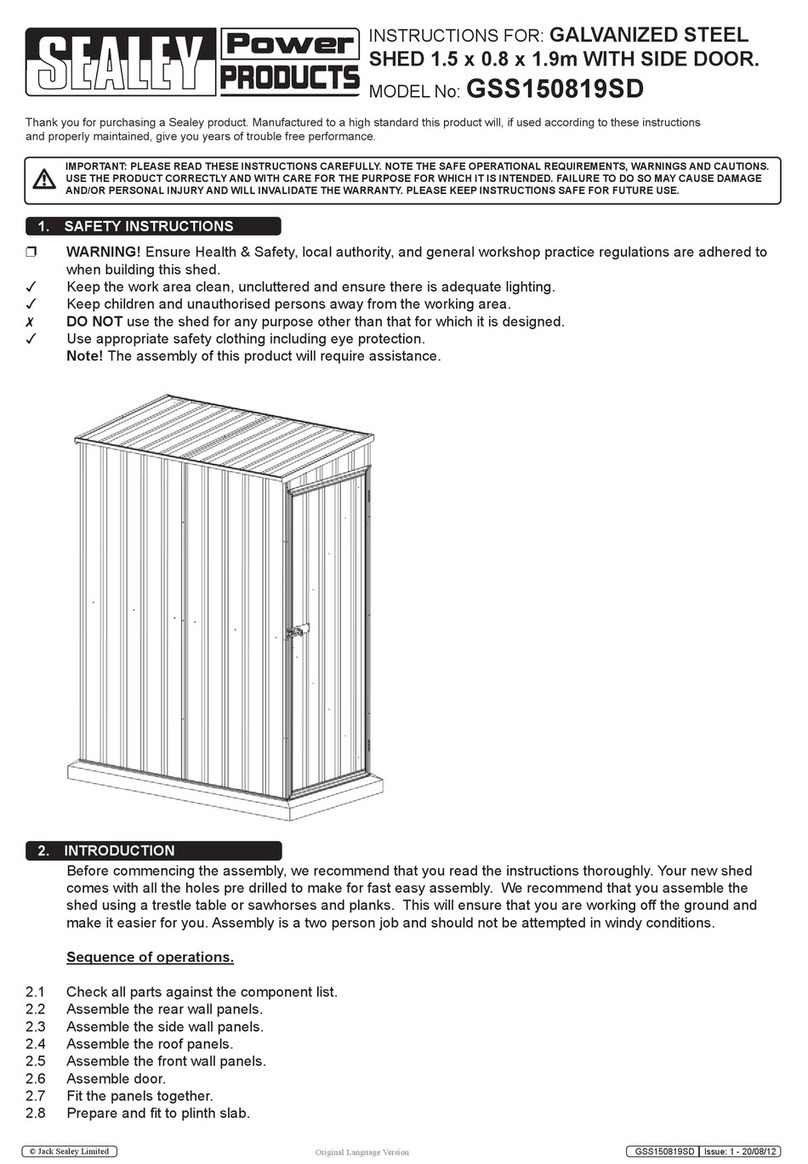

FRAME ASSEMBLY

STEP 3 - before you start!

It is recommended that all LYSAGHT®carports are assembled and

installed under the supervision and direction of a person with some

level of building experience.

Safety is of utmost importance at all times. Always make sure that

even basic construction tasks are done utilising safe building

practices.

It is very important to read both the installation instructions and

the supplied construction drawing. They should both be referred

to in preparation for the installation and at every step during the

construction process.

Every dimension, hole location and level should be double

checked for good measure before cutting, fixing, screwing or

bolting to any structural component.

Your carport is designed to resist wind uplift and the footing size

is based on the wind classification. If in doubt, go to the Lysaght

website (www.lysaght.com) and use the wind classification system

to check the design wind speed or seek expert advice to ensure

correct wind classification is selected.

If you do not have the necessary tools or know-how, please

contact your local Lysaght branch for guidance.

STEP 4 - marking out the carport position

Use in-ground stakes and tie up string lines to position the steel

post locations referring to the construction drawing. Check

diagonals are equal for a square shape.

FIRMLOK®beams and SPANDEK®sheeting lengths are reliant upon

these measures being 100% accurate.

Check depth and width of the footing according to the

construction drawing and remove soil.

Mark and cut posts to length and prepare the bottom of

the posts as per the construction drawing with intersecting

fixings and add the connectors to the top of the posts.

Ensure the footings holes are aligned and the final intended

locations of posts correct in accordance with the construction

drawing. Slopes of the ground will need to be taken into

consideration to ensure holes are dug to appropriate depth

and posts are subsequently aligned in terms of height.

Once the digging is complete, simply place bricks/pavers squarely

in the bottom of each hole so the posts can be positioned on solid

ground.

Place the posts in the holes and clamp off in position and brace

with a fall towards the end at which the gutter system will be

positioned. The fall needs to be a minimum 30mm for every 1m in

length.

STEP 2 - what tools & materials do you need?

• Step ladder

• Hack saw

• Tape measure

• Pliers and tin snips

• Angle grinder

• Spirit or laser level

• Rivet gun

• Post hole digger or shovel

• PVC downpipe & strap

• Electrical lead

• PVC downpipe elbow

• Silicone gun & clear silicone

• String line/ stakes

• Ratchet wrench

• Safety equipment (PPE)

• Adjustable stands (props)

and clamps

• Adjustable spanner

• Bags of concrete

• Drill & adaptors

• Saw horses and planks