R3-NP1

P. 1 / 4EM-8418 Rev.3

PROFIBUS-DP INTERFACE MODULE MODEL R3-NP1

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Network interface module............................................ (1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■ CONFORMITY WITH EC DIRECTIVES

• The equipment must be mounted inside the instrument

panel of a metal enclosure.

• The actual installation environments such as panel con-

figurations, connected devices and connected wires may

affect the protection level of this unit when it is integrated

in a panel system. The user may have to review the CE

requirements in regard to the whole system and employ

additional protective measures to ensure CE conformity.

■ POWER INPUT RATINGS

Operational range & power consumption: Check the power

rating for the unit on the specification label.

Rating 100 – 120V AC: 85 – 132V, 47 – 66 Hz, approx. 20VA

Rating 200 – 240V AC: 170 – 264V, 47 – 66 Hz, approx. 20VA

Rating 24V DC: 24V

±

10%, approx. 12W

■ UNPLUGGING THE MODULE

Before you remove the module from its base or mount it,

turn off the power supply for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ven-

tilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -10 to +55°C

(14 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

■ WIRING

• Do not install cables (power supply, input and output)

close to noise sources (relay drive cable, high frequency

line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for sat-

isfying complete performance described in the data sheet.

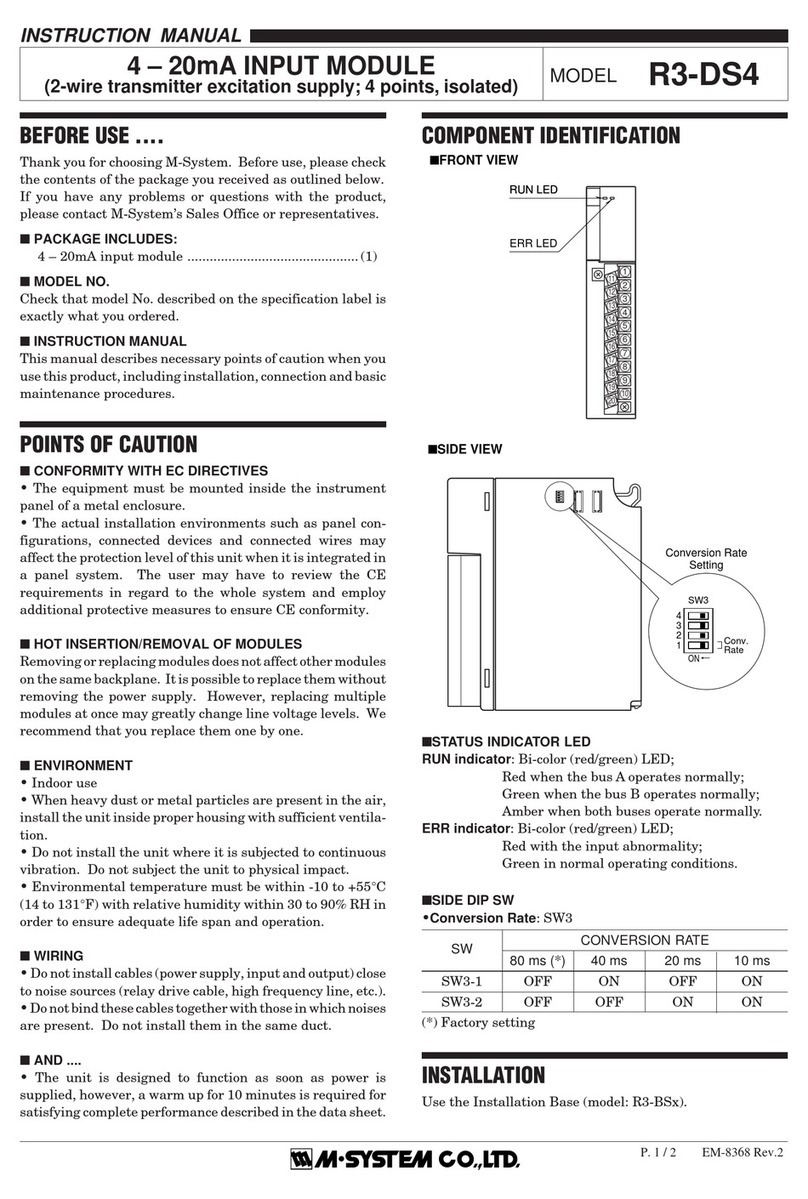

INSTALLATION

Use the Installation Base Model R3-BSx, or Model R3-

BSWx for free I/O address capability.

Before mounting the Network Interface Module onto the

Base, be sure to configure the module as explained below.

■ NODE ADDRESS

See “COMPONENT IDENTIFICATION.”

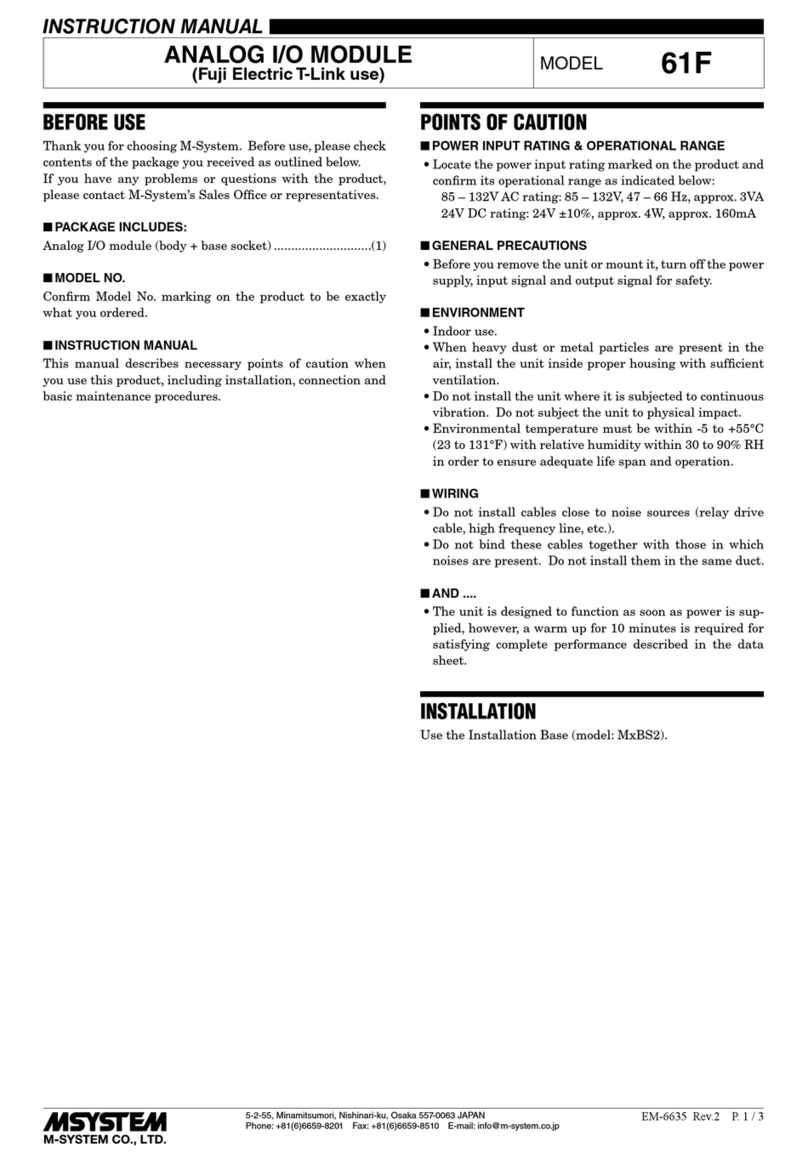

■ NETWORK SLOTS ON THE BASE

With Model R3-BSx base, mount the I/O Modules from the

left end (I/O 1) to the right in order that the Network Mod-

ule assigns data areas from I/O 1.

Network Module(s) and Power Module are mounted basi-

cally at the right end though technically they could be

mounted in any position.

With Model R3-BSWx base, there is no limitation in mount-

ing positions as I/O address can be assigned freely to each

module using rotary switches equipped on the base.