1.1 Overview

The Apollo III is MachMotion's Ethernet motion controller. It uses differential or single-ended step and direction to

control up to 6 axes with full encoder feedback (full closed loop). It also has 16 inputs, 8 outputs, excellent position

resolution, two MPG inputs, and spindle encoder feedback.

See the overview video on our youtube channel:

https://www.youtube.com/watch?v=g3n247P9wUM

1.2 Tools Required

A small, flat head screwdriver is needed for the I/O terminals.

Small needle nose pliers may be needed to move jumpers for the inputs.

1.3 Reference Diagram

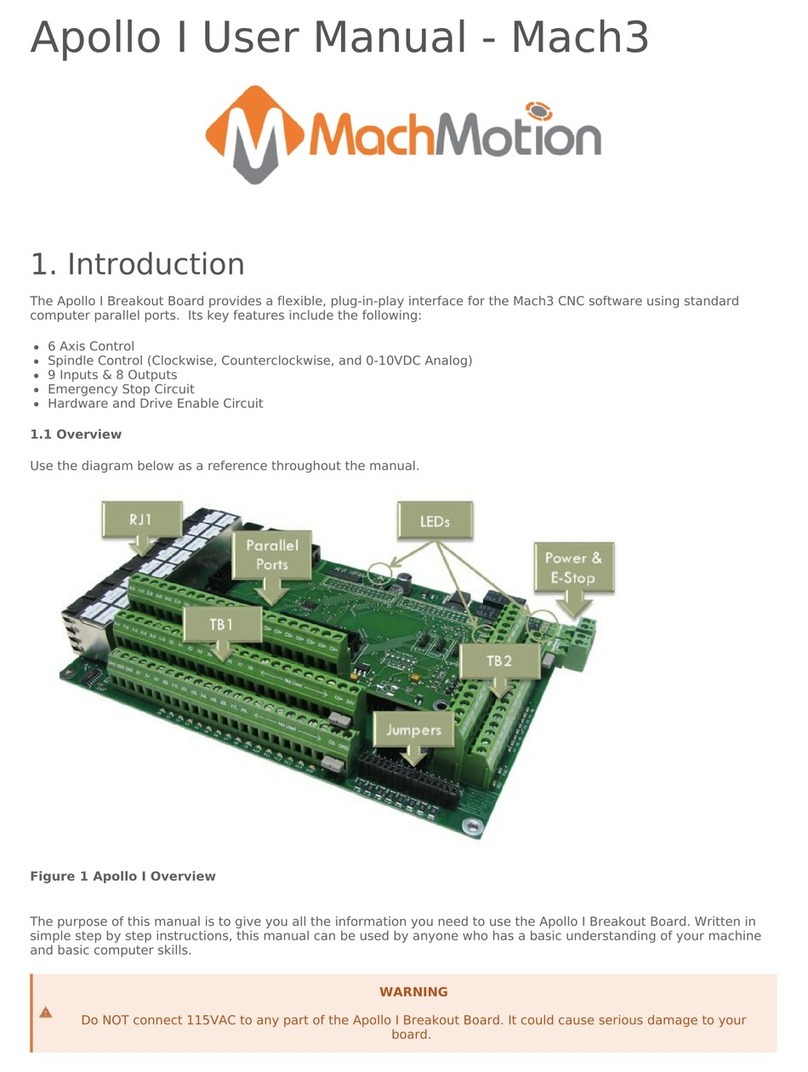

Use the diagram below as a reference throughout the manual.

Figure 1 Apollo III Overview

1.4 Status LEDs

The Apollo III has four status LEDs that show the status of the controller’s processor. The LEDs are located close to the

center of the controller. See the figure below.

WARNING!

Improper installation of this motion controller can cause DEATH, INJURY or serious PROPERTY

DAMAGE. Do not attempt to install this controller until thoroughly reading and understanding this

manual.

WARNING!

Do NOT connect DC voltage greater than 48V, or any AC voltage to any part of the Apollo III motion

controller.

It could cause serious damage to the controller.

1 Introduction

WARNING

DO NOT connect 115VAC to any part of the Apollo III motion controller.

It could cause serious damage to the controller.