MS16

0709

0006

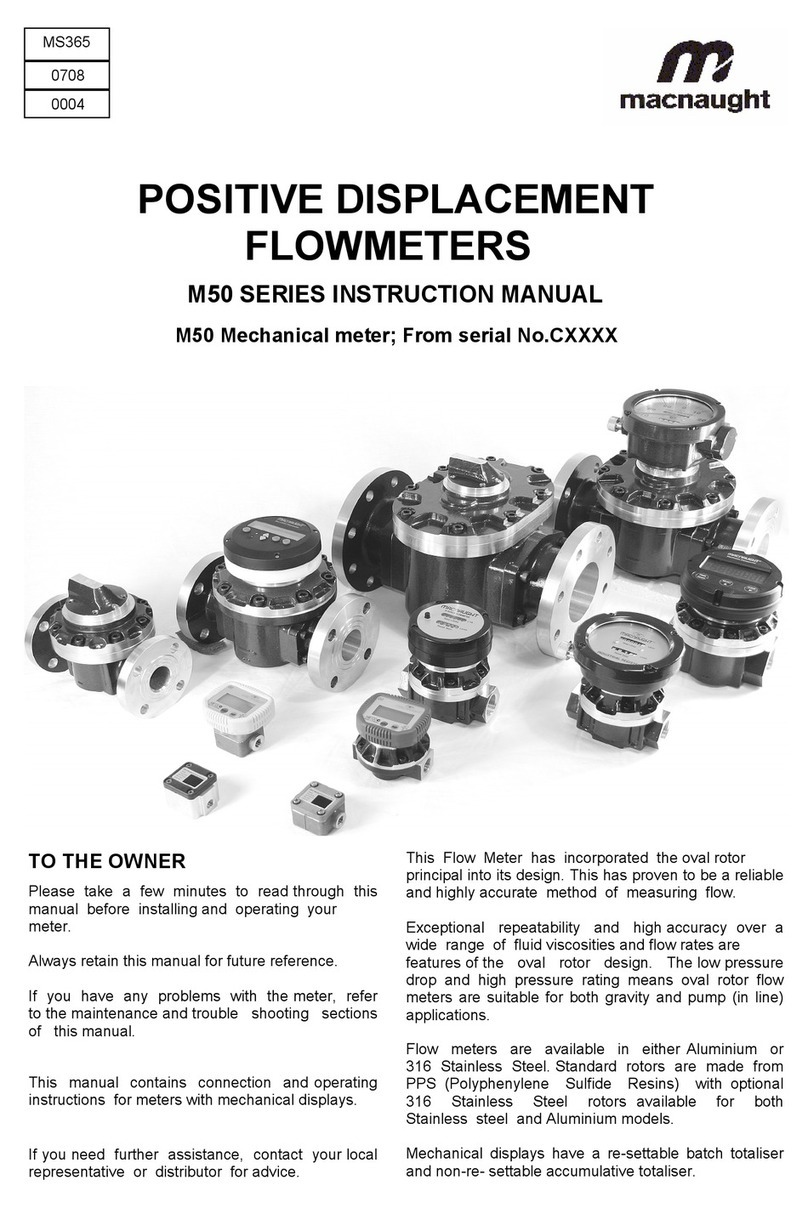

POSITIVE DISPLACEMENT

FLOWMETERS

M1 SERIES INSTRUCTION MANUAL

TO THE OWNER

Please take a few minutes to read through this

manual before installing and operating your

meter.

Always retain this manual for future referen e.

If you have any problems with the meter, refer

to the maintenan e and trouble shooting

se tions of this manual.

This manual ontains onne tion and operating

instru tions for the meters. If you need further

assistan e, onta t your lo al representative or

distributor for advi e.

This Flowmeter has in orporated the oval rotor

prin ipal into its design.

This has proven to be a reliable and highly a urate

method of measuring flow.

Ex eptional repeatability and high a ura y

over a wide range of fluid vis osities and flow

rates are features of the oval rotor design. With low

pressure drop and high pressure rating means

oval rotor flow meters are suitable for both gravity

and pump (in-line) appli ations.

Flowmeters are manufa tured in either PPS

(Polyphenylene Sulfide Resins) , Aluminium & 316

Stainless Steel.

Standard rotors are made from 316 Stainless Steel

with optional PPS rotors with Hastalloy C Shafts

available.

OPERATION

Before use, confir the fluid to be used is co -

patible with the eter. Refer to Industry fluid

co patibility charts or consult your local

representative for advice.

To prevent da age fro dirt or foreign atter it

is reco ended that a Y or basket type 200

esh strainer be installed as close as possible

to the inlet side of the eter. Contact your

local representative for advice.

PLEASE READ THIS INFORMATION

CAREFULLY BEFORE USE!

Note:

To prevent da age to the eter slowly fill the

syste with fluid (this will prevent da age

caused by air purge).

Failure to do this could da age the eter.

To reduce pressure build up turn off the pu p at

the end of each day.