Page 4 of 31

INSTALLATION PROCEDURE

1. It is recommended that a bypass line be included

in the design. This provides the facility for a

meter to be removed for maintenance without

interrupting production. (see figure)

2. Use a thread sealant on all pipe threads. Thread

tape must not enter flow meter as this could stop

flow meters operation.

3. For pump applications ensure pipe work and

meter have the appropriate working pressure

rating to match the pressure output of the pump.

Refer to meter specifications section for further

details. (Page 7)

4. Install a Y type or basket type mesh strainer as

close as possible to the inlet side of the meter.

Meter 1/4” 74 micron / 200 mesh

Meter 1/2”- 2” 250 micron / 60 mesh

Meter 3”- 4” 420 micron / 40 mesh

The flow meter can accept flow in any direction.

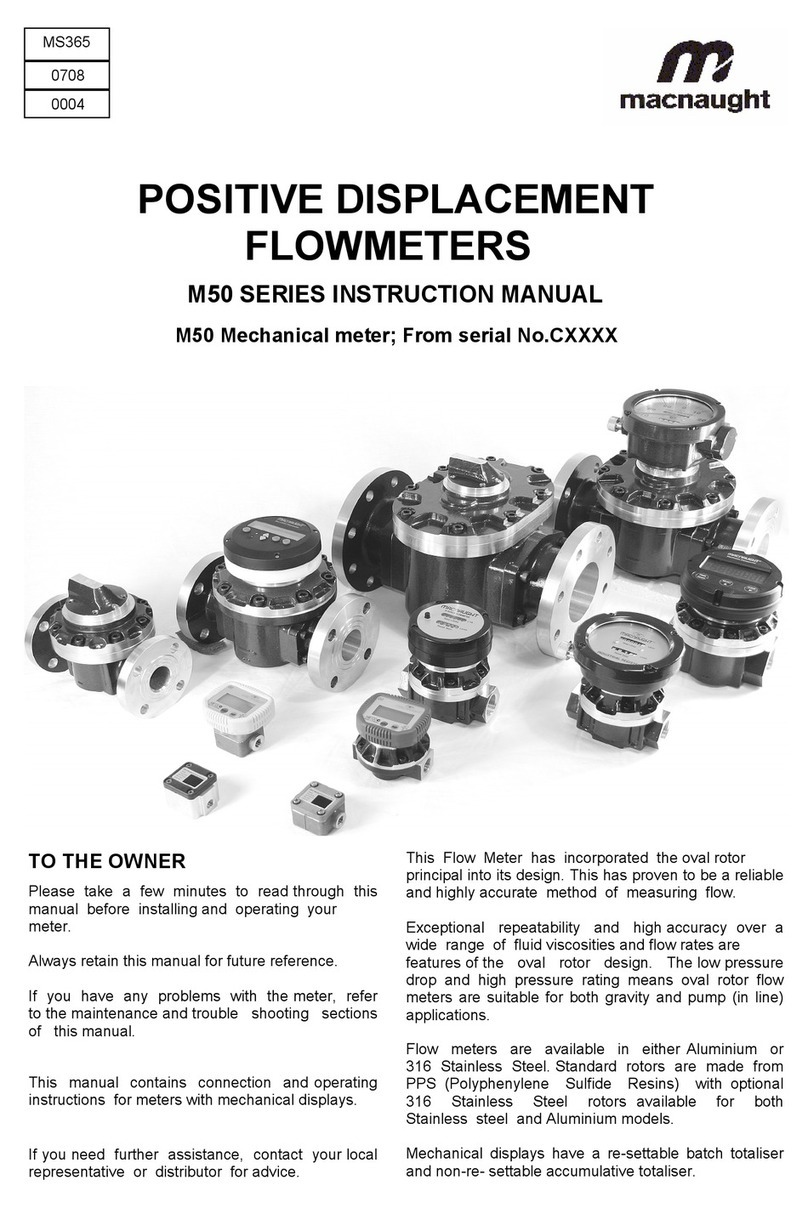

5. The meter can be installed in any orientation as

long as the meter shafts are in a horizontal

plane as per the picture.

Incorrect installation can cause premature wear of

meter components.

Do not over tighten meter connections.

7. It is important after initial installation to fill the line

slowly, high speed air purge could cause damage

to the rotors.

8. Test the system for leaks. Do not continue use if

meter is leaking.

9. Check the strainer for swarf or foreign material,

after the first 200 litres, check periodically,

particularly if the flow rate is noted to be

decreasing.

When maintenance to any part of the flow meter is required, it must be isolated and line pressure released. It

must be removed from the line if required. Use non sparking tools to accomplish the job.

It is advisable to mark all components with a marker pen before disassembly, to ensure all the components are

replaced to their correct position during the reassembly process.

1. Remove the meter cap by loosening the bolts on the underside of the meter body. (see FIG 1, Page 6)

2. Remove the O-Ring from the O-Ring groove. Clean it nicely and store in clean place.

3. Remove rotors from the cap and shaft assembly. The shafts are fixed to the cap for sizes 1/4” - 2” and to the

body for 3” and 4” sizes. No need to take them off.

Do not remove shafts from their location.

Inspection and maintenance should only be carried out by experienced personnel.

MAINTENANCE PROCEDURE

DIS-ASSEMBLY