Wiring the Data Logger

Wiring Options

The QuadProcess and OctProcess both have two-position removable screw terminal

connections. The QuadProcess has 4 connections, the OctProcess has 8 connections. They

accept 3-wire configurations.

Warning: Note the polarity instructions. Do not attach wires to the wrong terminals.

Product Notes

Engineering Units

Engineering units are used to convert one measurement reading to another. The

MadgeTech software allows for software level Engineering Units (conversion applied to

data after download). Certain devices have device level Engineering Units, which upon

download automatically appear in the chosen unit of measure.

Please refer to the application note “Engineering Units”, found on the MadgeTech website,

for information on how to manage Engineering Units. Also view the Engineering Units

Video for step-by-step setup instructions.

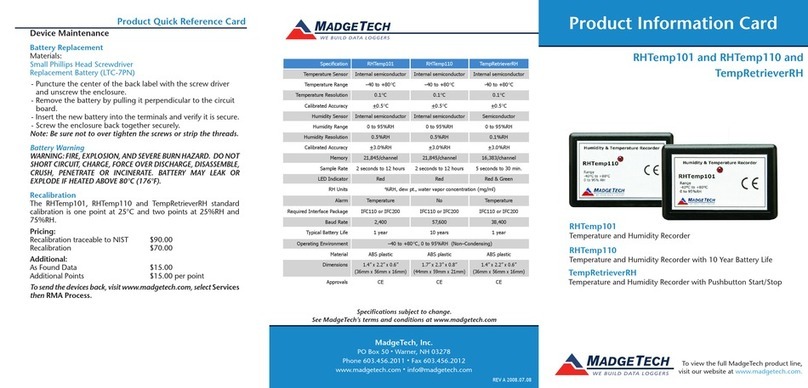

Device Maintenance

Battery Replacement

Materials: 3/32” HEX Driver (Allen Key) and a Replacement Battery (U9VL-J)

- Remove the cover from the device by unscrewing the four screws.

- Remove the battery from its compartment and unsnap it from the connector.

- Snap the new battery into the terminals and verify it is secure.

- Replace the cover taking care not to pinch the wires. Screw the enclosure back together

securely. Note: Be sure not to over tighten the screws or strip the threads.

Recalibration

The QuadProcess or OctProcess standard calibration is at two points. The points are

dependent on the range of the data logger.

Pricing:

Recalibration traceable to NIST $69.00

Recalibration $49.00

Additional Services:

As Found Data $15.00 per parameter/channel

Verification Point $15.00 per point

Prices and specifications subject to change. See MadgeTech’s terms and conditions at www.madgetech.com

To send the devices back, visit www.madgetech.com, select Services then RMA Process.

Product Quick Reference Card

QuadProcess and OctProcess

Installation Guide

Installing the Interface cable

- IFC200

Insert the device into a USB port. The drivers will install automatically.

- IFC110

Plug the serial cable into the port and verify it is secure.

Installing the software

Insert the Software CD in the CD-ROM Drive. If the autorun does not appear, locate the

drive on the computer and double click on Autorun.exe. Follow the instructions provided

in the Wizard.

Connecting the data logger

- Once the software is installed and running, plug the interface cable into the data logger.

- Click the Communication Menu, then Auto Configure Port.

- After a moment, a box will appear stating a device has been found.

- Click OK. The Device Status box will appear. Click OK.

- At this point, communications have been configured for your logger. These settings can

be found under the Communication Menu.

Note: For additional installation instructions refer to your “Data Logger & Software Operating Manual”.

Device Operation

Starting the data logger

- Click Device Menu then Start Device.

- Choose the desired start method.

- Choose the start parameters by selecting a Reading Rate suitable for your application.

- Enter in any other desired parameters and click Start.

- A box will appear stating the data logger has been started. Click OK.

- Disconnect the data logger from the interface cable and place it in the environment to

measure.

Note: The device will stop recording data when the end of memory is reached or the device is stopped. At this point the device

cannot be restarted until it has been re-armed by the computer.

Downloading data from a data logger

- Connect the data logger to the interface cable.

- Click the Device Menu then Read Device Data. This will offload all recorded data onto

the PC.

Range 1mA 25mA 100mA

Calibration Points 0mA and .9-1mA 0mA and 22.5-25mA 0mA and 90-100mA