Page v © 2014 Magnum Energy, Inc.

List of Figures

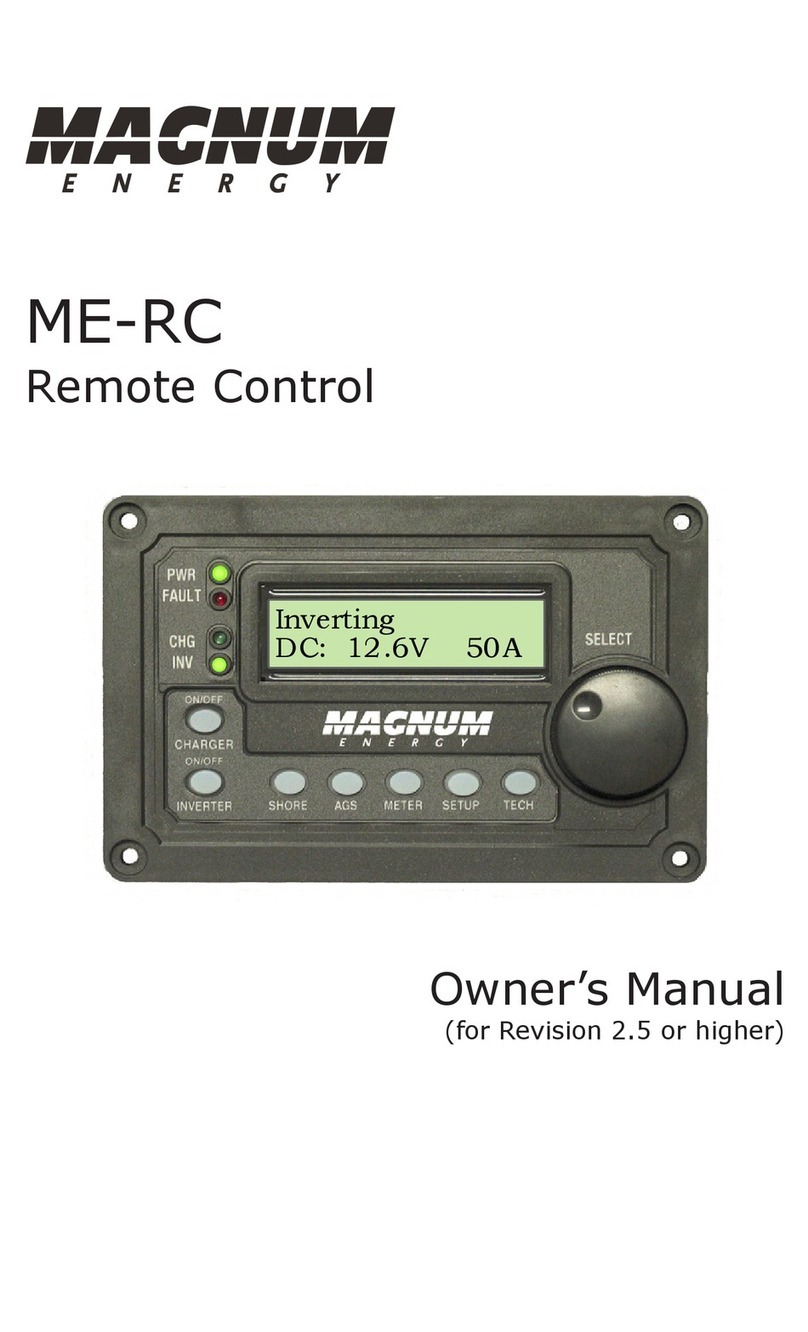

Figure 1-1, Front Panel Features ..................................................................................... 1

Figure 2-1, Remote Cable .............................................................................................. 3

Figure 2-2, Remote Control Connections .......................................................................... 3

Figure 2-3, ME-ARC Remote Dimensions .......................................................................... 4

Figure 2-4, Remote Bezel Dimensions ............................................................................. 4

Figure 2-5, Flush Mounting the ME-ARC ........................................................................... 5

Figure 2-6, Surface Mounting the ME-ARC using the Bezel.................................................. 6

Figure 2-7, Power-up Self Test Screens............................................................................ 7

Figure 2-8, Self Test Set Clock Screens............................................................................ 7

Figure 3-1, Front Panel Setup Features............................................................................ 8

Figure 3-2, SETUP Menu Navigation ................................................................................ 9

Figure 3-3, FAVS Button and Menus ...............................................................................11

Figure 3-4, CTRL Button and Menus ...............................................................................12

Figure 3-5, METER Button and Menus.............................................................................15

Figure 3-6, Current Flow – Inverter Mode .......................................................................17

Figure 3-7, Current Flow – Standby Mode .......................................................................17

Figure 3-8, Current Flow – Load Support Mode ................................................................17

Figure 3-9, SETUP Button and Menus .............................................................................19

Figure 3-10, CV Charge Done Time/Amps Stages (INV/CHG).............................................28

Figure 3-11, Hold CV Chg VDC Charge Stages (INV/CHG) .................................................30

Figure 3-12, Final Charge Stage – Multi-Stage.................................................................34

Figure 3-13, Final Charge Stage – Float ..........................................................................34

Figure 3-14, Final Charge Stage – Silent.........................................................................34

Figure 3-15, TECH Button and Menus .............................................................................36

Figure 3-16, Inverter Fault History Screens .....................................................................37

Figure 4-1, FAVS/CTRL/METER Button Menu Maps............................................................40

Figure 4-2, SETUP Button Menu Map ..............................................................................41

Figure 4-3, SETUP Button Menu Map ..............................................................................42

Figure 4-4, SETUP/TECH Button Menu Maps ....................................................................43

Figure 4-5, TECH Button Menu Map................................................................................44

Figure 5-1, ME-ARC Front Panel Controls and Indicators....................................................45

Figure 5-2, System Status Screen (Example) ..................................................................47

Figure 7-1, AGS Fault History Screens ............................................................................76

Figure 7-2, AGS CTRL/METER Menu Map (Section 1) ........................................................78

Figure 7-3, AGS SETUP Menu Map (Section 2) .................................................................79

Figure 7-4, AGS SETUP Menu Map (Section 3) .................................................................80

Figure 7-5, AGS SETUP/TECH Menu Map (Section 4) ........................................................81

Figure 7-6, AGS Fault Message (Example).......................................................................85

Figure 8-1, Ending Battery Voltage Verses Time...............................................................90

Figure 8-2, BMK METER/SETUP Menu Map.......................................................................92

Figure 8-3, BMK Fault Message (Example) ......................................................................94

Figure 9-1, ACLD METER Menu Map ...............................................................................96

Figure 9-2, ACLD Fault Message (Example) .....................................................................98

Figure 10-1, CV Charge Done Time/Amps (PT Controller)................................................ 101

Figure 10-2, Hold CV Charge Volts (PT Controller).......................................................... 102

Figure 10-3, Multi-Stage Charging (PT Controller) .......................................................... 103

Figure 10-4, PT Fault History Screens ........................................................................... 114

Figure 10-5, PT Charge Controller CTRL/METER Menu Map .............................................. 115