The Majestic Shower Company Limited

One North Place, Edinburgh Way, Harlow Essex

CM20 2SL England,

Telephone +44 (0) 8448 001 500

Facsimile +44 (0) 1279 635 074

info@majesticshowers.com www.majesticshowers.com

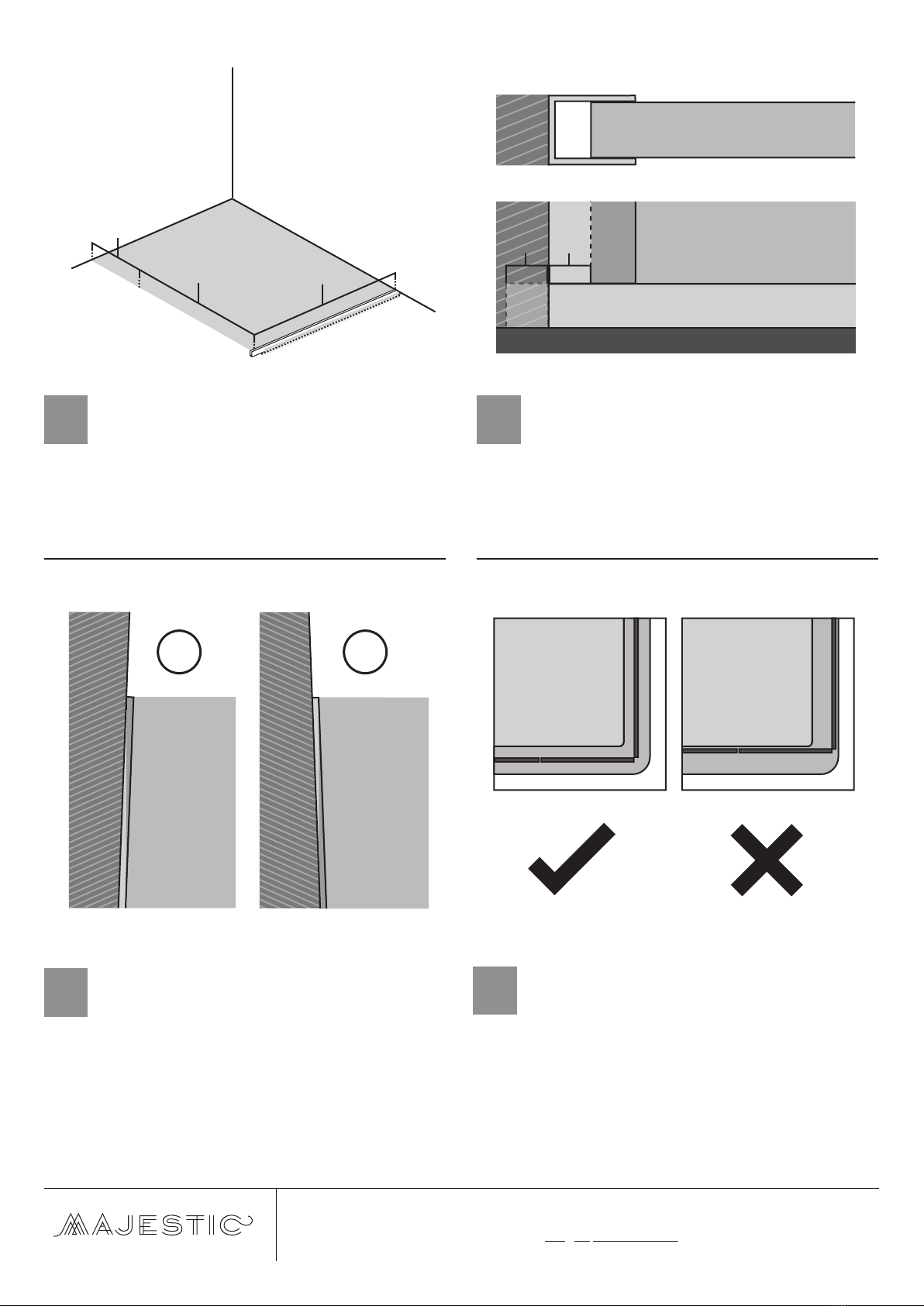

Portofino Corner Enclosure

THIS BOX SHOULD CONTAIN THE FOLLOWING:

Vertical wall profile x2

Horizontal Floor Profile x2

Black rubber strips x2

1xrecapsmm01

Glass door panel x1

Glass in-line panel x1

Glass return panel x1

Glass-to-glass hinges x2

Glass-to-wall brackets x4

(inc. Rawl plugs, screws, screw covers)

2mm Allen key x1

4mm Allen key x1

Door mounting blocks x2

1936 door-to-glass seal x1

1956 glass-to-door seal x1

1915 Under-door seal x1

Door handle set x1

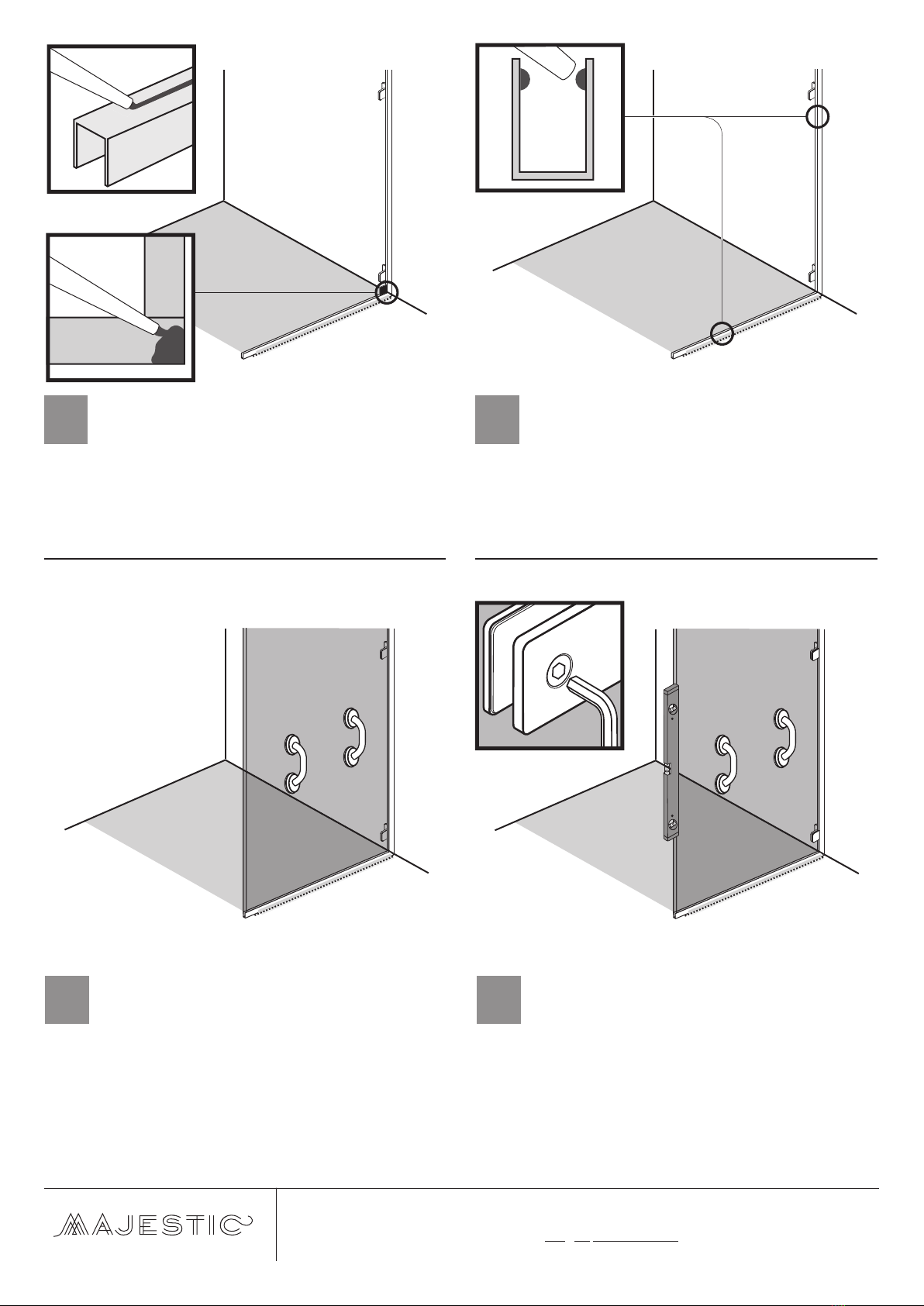

TOOLS REQUIRED:

2x suction glass lifters

Spirit Level

Setsquare

Power drill/driver

Hacksaw

Junior Hacksaw

Fine tooth file

Sealant gun

High-quality silicone

Pencil

Metal Scriber

Masking tape

Measuring tape

IMPORTANT:

Please check the glass and all components thoroughly

before installation; if any of the parts have been supplied

incorrectly or are damaged, contact Majestic immediately.

Any faults with the product found after installation cannot

be rectified and Majestic will not be held responsible for

re-installation of faulty or marked goods.

Unwrap all parts carefully to avoid damaging the chrome

fittings!

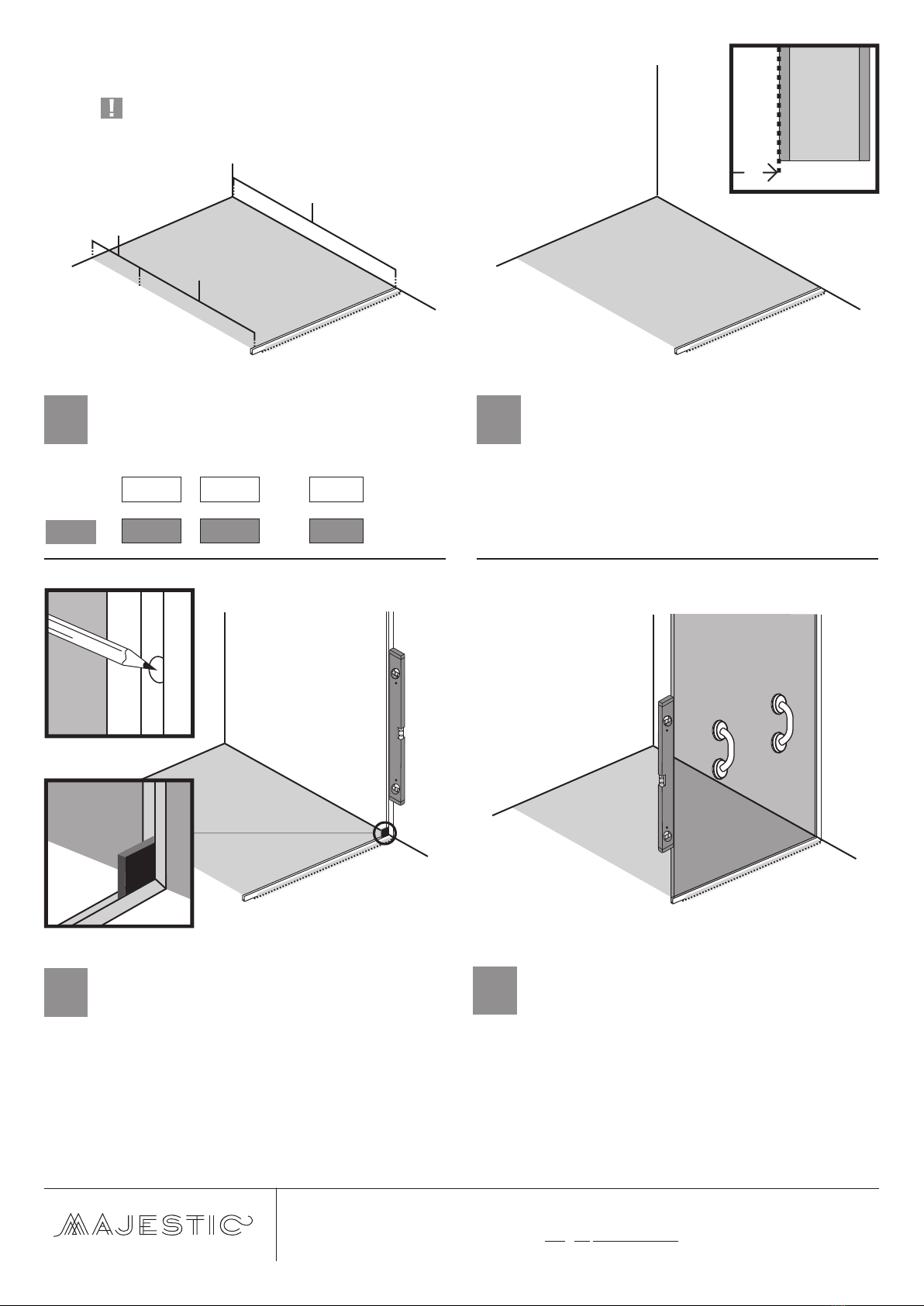

This unit must be fitted on a level surface, unless the glass

has been cut to suit any slope in the floor.

Whether fitting to a tiled floor or tray, ensure the area is

degreased, dust free and level.

Do not place the glass panels on hard surfaces! Cover any

hard surfaces you are working on with a cushioned

material, to help prevent the glass from shattering on

contact.

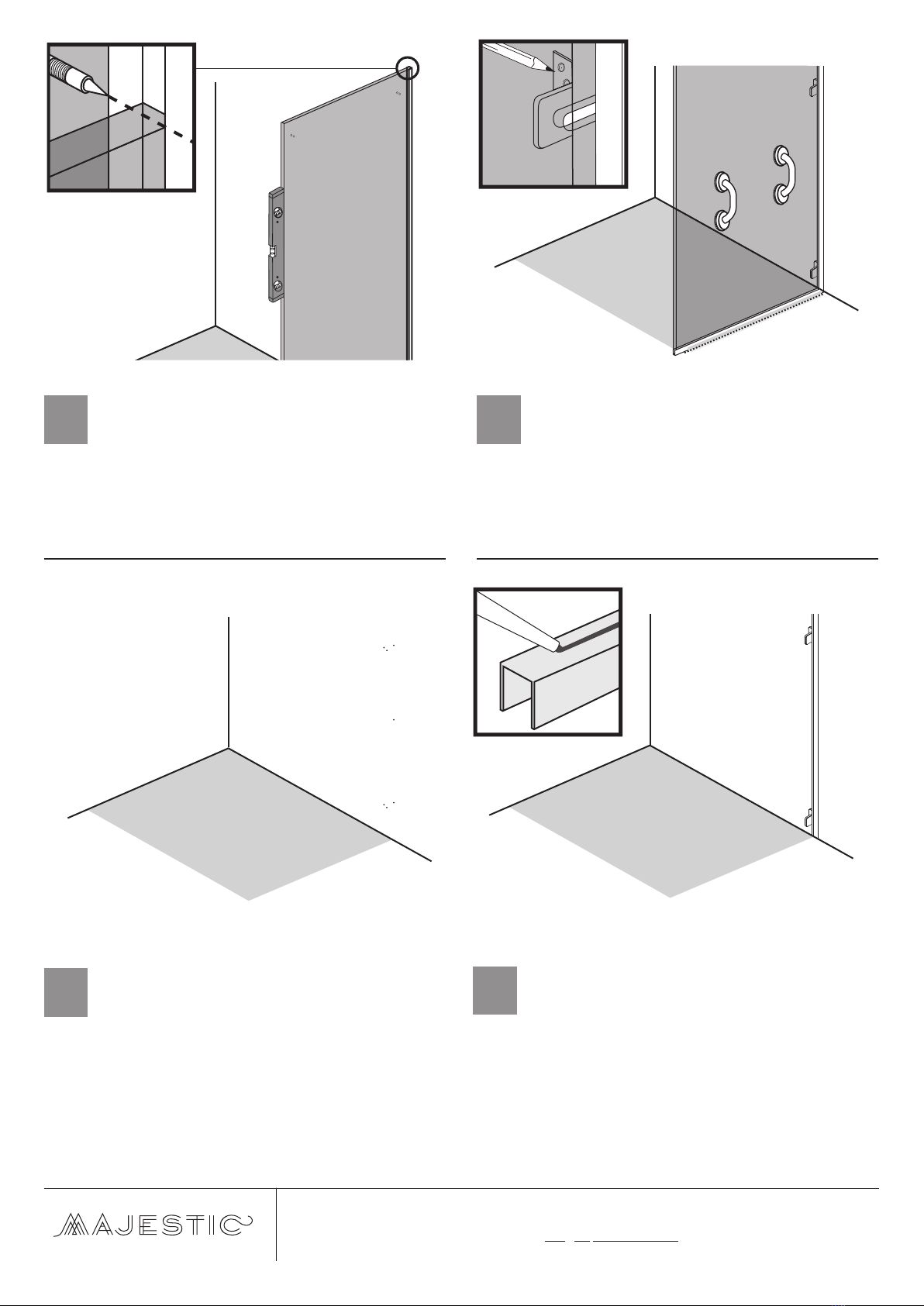

Before commencing the installation, please familiarise

yourself with the glass-handling guide attached to the

glass panels. Where appropriate, the top end of the glass

panels will be indicated.

If you have purchased anti-calcium glass, the treated side

of the glass will be indicated and should always face

towards the inside (wet side) of the shower enclosure.

Certain sections of the installation of this shower enclosure

require two people.