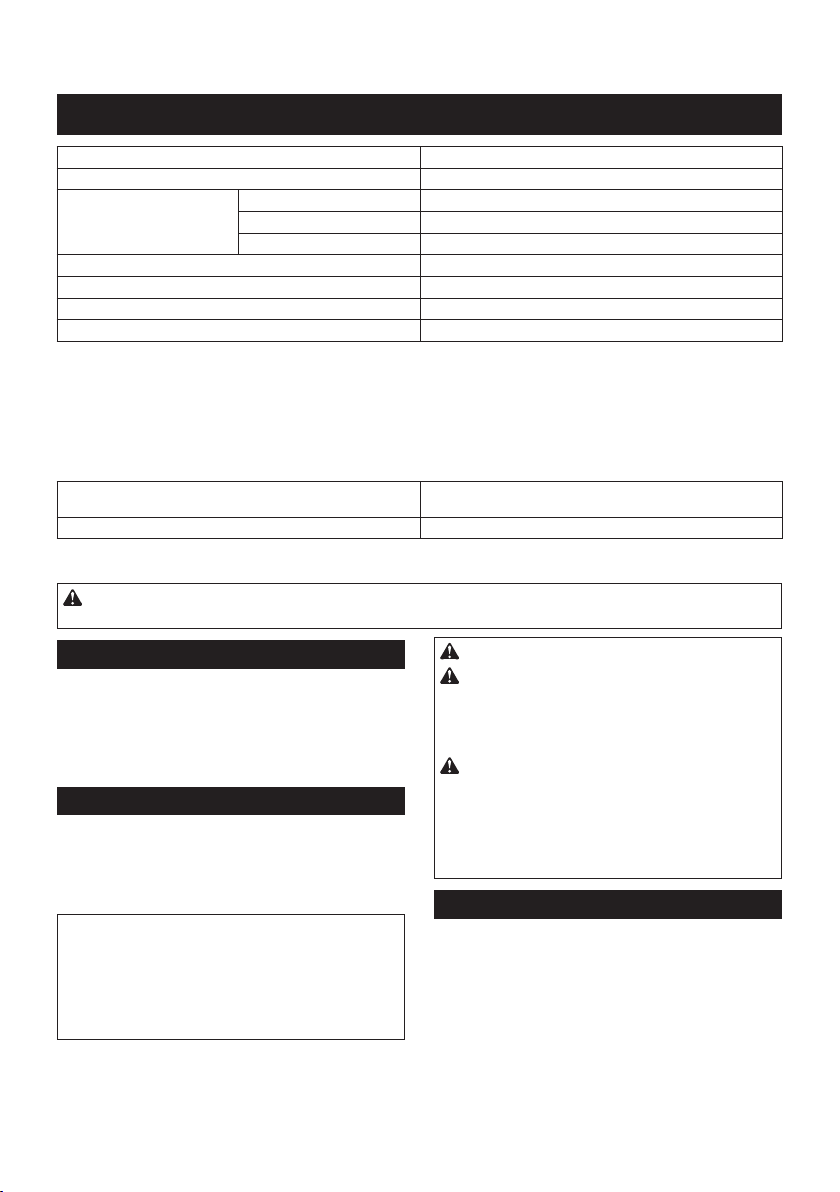

10 ENGLISH

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

andmaybeusedforcomparingonetoolwithanother.

NOTE:Thedeclaredvibrationtotalvalue(s)mayalso

beusedinapreliminaryassessmentofexposure.

WARNING: The vibration emission during

actual use of the power tool can dier from the

declared value(s) depending on the ways in which

the tool is used especially what kind of workpiece

is processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

o and when it is running idle in addition to the

trigger time).

EC Declaration of Conformity

For European countries only

TheECdeclarationofconformityisincludedasAnnexA

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING Read all safety warnings, instruc-

tions, illustrations and specications provided with

this power tool. Failure to follow all instructions listed

belowmayresultinelectricshock,reand/orserious

injury.

Save all warnings and instruc-

tions for future reference.

Theterm"powertool"inthewarningsreferstoyour

mains-operated(corded)powertoolorbattery-operated

(cordless) power tool.

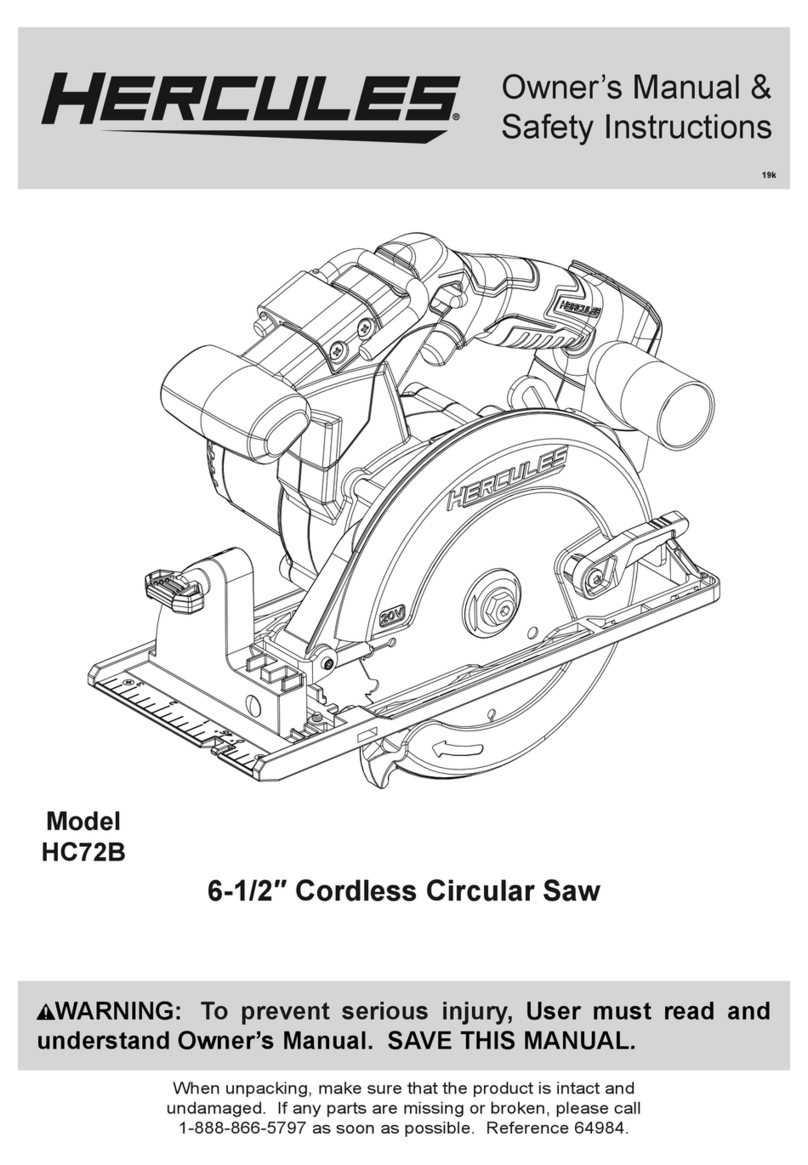

Cordless circular saw safety warnings

Cutting procedures

1. DANGER: Keep hands away from cutting

area and the blade. Keep your second hand

on auxiliary handle, or motor housing. If both

handsareholdingthesaw,theycannotbecutby

the blade.

2. Do not reach underneath the workpiece. The

guardcannotprotectyoufromthebladebelowthe

workpiece.

3. Adjust the cutting depth to the thickness of

the workpiece. Less than a full tooth of the blade

teeth should be visible below the workpiece.

4. Never hold the workpiece in your hands or

across your leg while cutting. Secure the

workpiece to a stable platform. It is important to

supporttheworkproperlytominimisebodyexpo-

sure, blade binding, or loss of control.

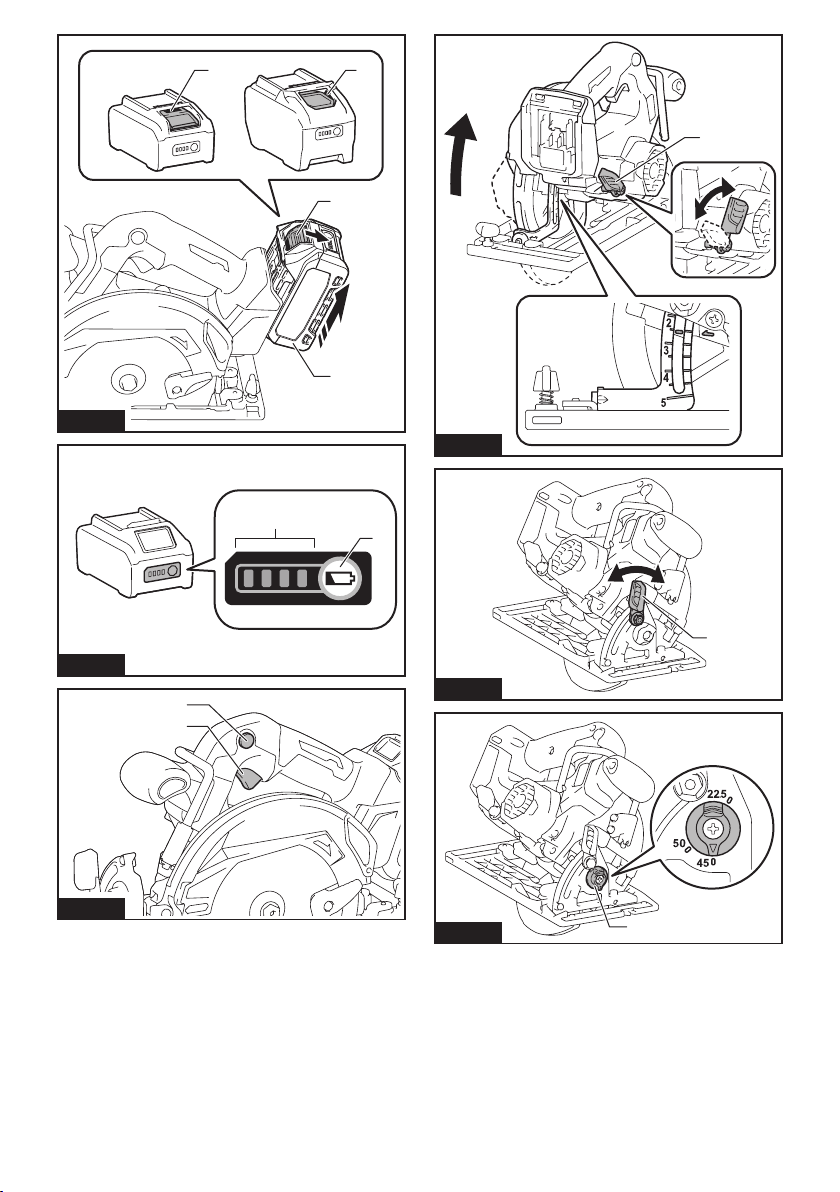

►Fig.1

5. Hold the power tool by insulated gripping

surfaces, when performing an operation where

the cutting tool may contact hidden wiring.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and could give

the operator an electric shock.

6. When ripping, always use a rip fence or

straight edge guide.Thisimprovestheaccuracy

of cut and reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes.

Blades that do not match the mounting hardware

ofthesawwillruno-centre,causinglossof

control.

8. Never use damaged or incorrect blade wash-

ers or bolt. The blade washers and bolt were

speciallydesignedforyoursaw,foroptimum

performanceandsafetyofoperation.

Kickback causes and related warnings

— kickback is a sudden reaction to a pinched,

jammedormisalignedsawblade,causingan

uncontrolled saw to lift up and out of the workpiece

toward the operator;

— whenthebladeispinchedorjammedtightlybythe

kerf closing down, the blade stalls and the motor

reactiondrivestheunitrapidlybacktowardthe

operator;

— if the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade

toclimboutofthekerfandjumpbacktowardthe

operator.

Kickbackistheresultofsawmisuseand/orincorrect

operating procedures or conditions and can be avoided

bytakingproperprecautionsasgivenbelow.

1. Maintain a rm grip with both hands on the

saw and position your arms to resist kickback

forces. Position your body to either side of the

blade, but not in line with the blade.Kickback

couldcausethesawtojumpbackwards,but

kickbackforcescanbecontrolledbytheoperator,

if proper precautions are taken.

2. When blade is binding, or when interrupting a

cut for any reason, release the trigger and hold

the saw motionless in the material until the

blade comes to a complete stop. Never attempt

to remove the saw from the work or pull the

saw backward while the blade is in motion

or kickback may occur. Investigate and take

corrective actions to eliminate the cause of blade

binding.

3. When restarting a saw in the workpiece, centre

the saw blade in the kerf so that the saw teeth

are not engaged into the material. If a saw blade

binds,itmaywalkuporkickbackfromthework-

piece as the saw is restarted.

4. Support large panels to minimise the risk of

blade pinching and kickback. Large panels tend

to sag under their own weight. Supports must be

placed under the panel on both sides, near the line

of cut and near the edge of the panel.

►Fig.2

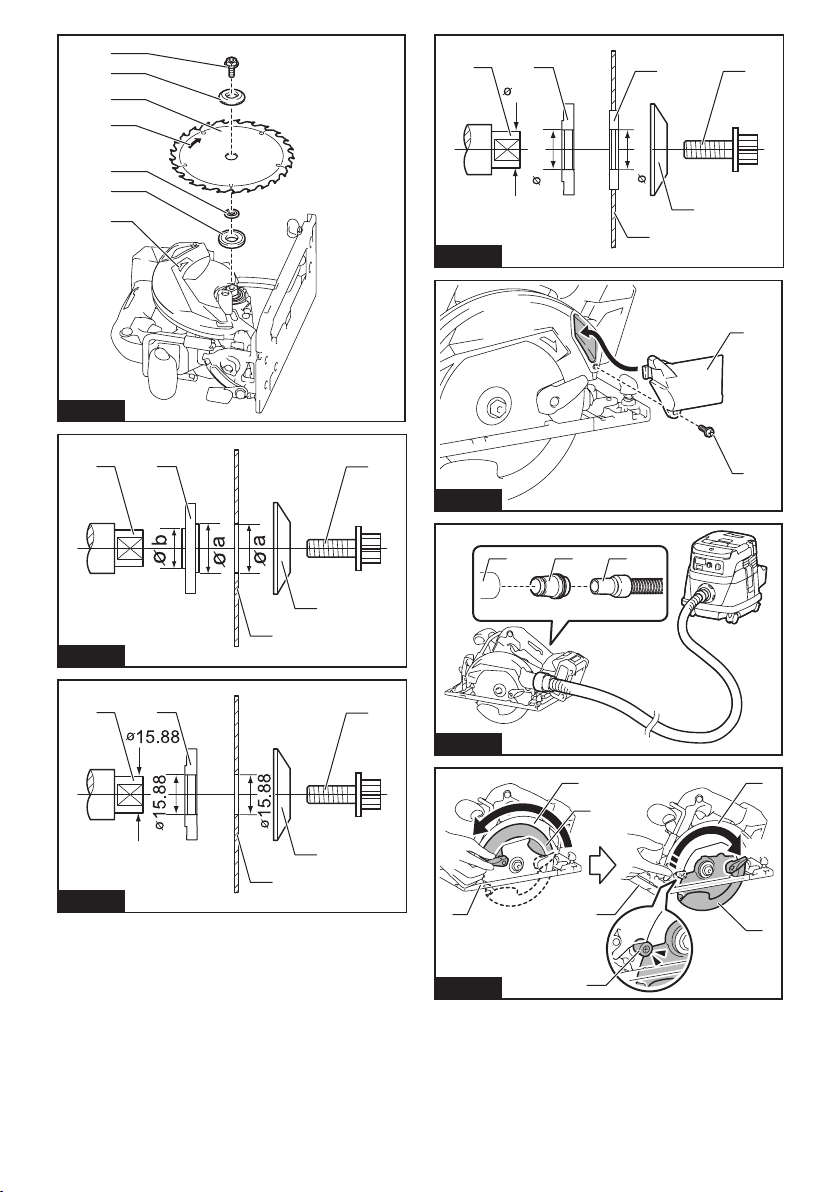

►Fig.3