4

source for this tool, the tool will explode and cause

serious injury.

•Always check the tool for its overall condition and

loose screws before operation. Tighten as

required.

•Make sure all safety systems are in working order

before operation. The tool must not operate if only

the trigger is pulled or if only the contact arm is

pressed against the wood. It must work only when

both actions are performed. Test for possible faulty

operation with nails unloaded.

•Check walls, ceilings, floors, roofing and the like

carefully to avoid possible electrical shock, gas

leakage, explosions, etc. caused by striking live

wires, conduits or gas pipes.

•Use only nails specified in this manual. The use of

any other nails may cause malfunction of the tool.

•Never use fastener driving tools marked with the

symbol “Do not use on scaffoldings, ladders”for

specific application for example:

- when changing one driving location to another

involves the use of scaffoldings, stairs, lad-

ders, or ladder alike constructions, e.g. roof

laths;

- closing boxes or crates;

- fitting transportation safety systems e.g. on

vehicles and wagons.

•Do not permit those uninstructed to use the tool.

•Make sure no one is nearby before nailing. Never

attempt to nail from both the inside and outside at

the same time. Nails may rip through and/or fly off,

presenting a grave danger.

•Watch your footing and maintain your balance with

the tool. Make sure there is no one below when

working in high locations, and secure the air hose

to prevent danger if there is sudden jerking or

catching.

•On rooftops and other high locations, nail as you

move forward. It is easy to lose your footing if you

nail while inching backward. When nailing against

perpendicular surface, nail from the top to the bot-

tom. You can perform nailing operations with less

fatigue by doing so.

•A nail will be bent or the tool can become jammed

if you mistakenly nail on top of another nail or strike

a knot in the wood. The nail may be thrown and hit

someone, or the tool itself can react dangerously.

Place the nails with care.

•Do not leave the loaded tool or the air compressor

under pressure for a long time out in the sun. Be

sure that dust, sand, chips and foreign matter will

not enter the tool in the place where you leave it

setting.

•Do not point the ejection port at anyone in the

vicinity. Keep hands and feet away from the ejec-

tion port area.

•When the air hose is connected, do not carry the

tool with your finger on the trigger or hand it to

someone in this condition. Accidental firing can be

extremely dangerous.

•Handle the tool carefully, as there is high pressure

inside the tool that can be dangerous if a crack is

caused by rough handling (dropping or striking).

Do not attempt to carve or engrave on the tool.

•Stop nailing operations immediately if you notice

something wrong or out of the ordinary with the

tool.

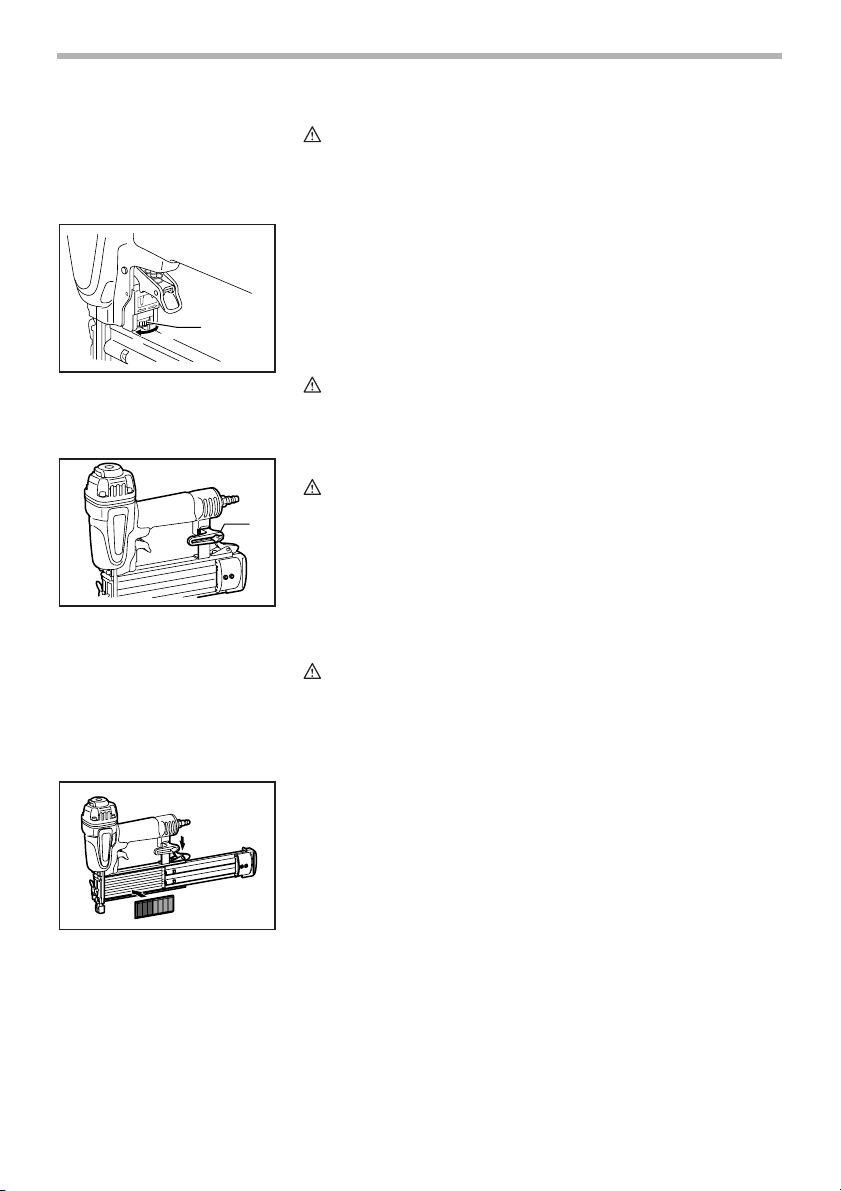

•Always disconnect the air hose and remove all of

the nails:

1.When unattended.

2.Before performing any maintenance or repair.

3.Before cleaning a jam.

4.Before moving the tool to a new location.

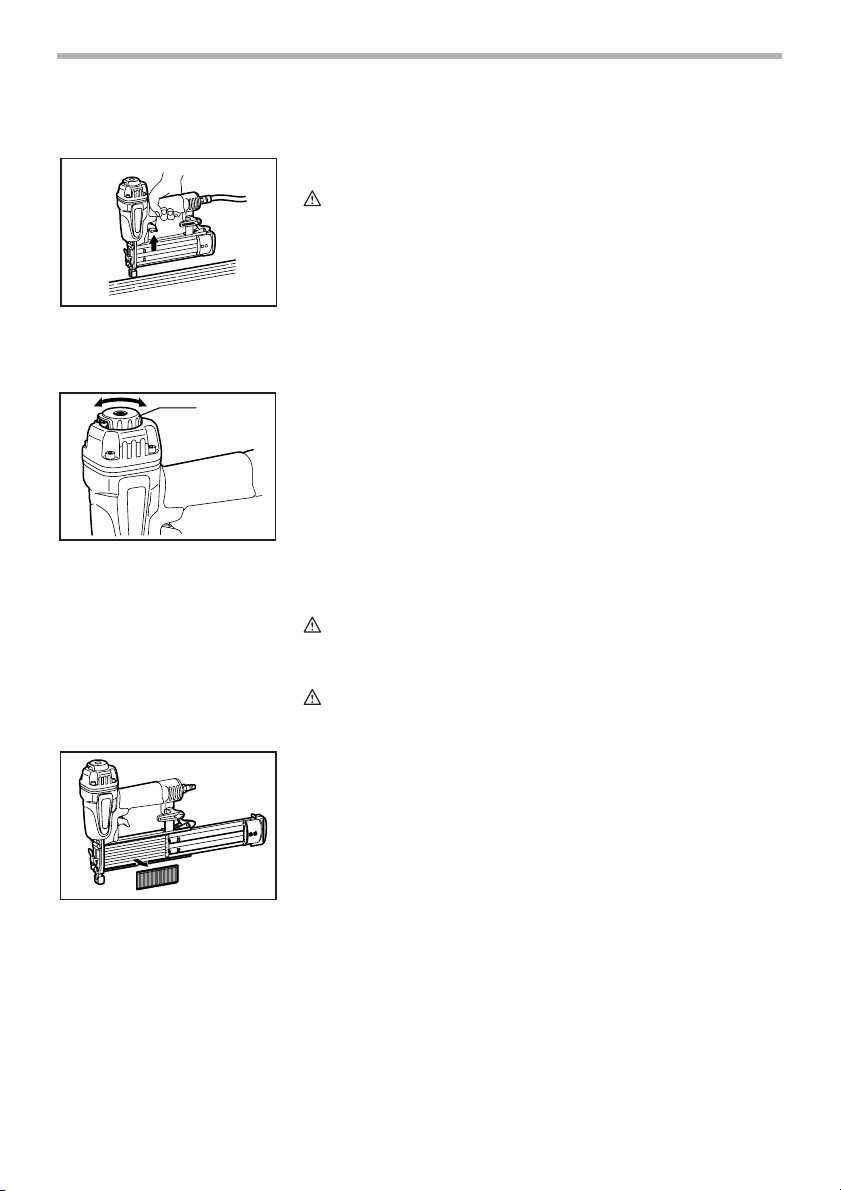

•Perform cleaning and maintenance right after fin-

ishing the job. Keep the tool in tip-top condition.

Lubricate moving parts to prevent rusting and mini-

mize friction-related wear. Wipe off all dust from

the parts.

•Do not operate this tool if it does not contain a legi-

ble WARNING LABEL.

•Do not modify tool without authorization from Mak-

ita.

•Ask Makita’s Authorized service centers for period-

ical inspection of the tool.

•To maintain product SAFETY and RELIABILITY,

maintenance and repairs should be performed by

Makita Authorized Service Centers, always using

Makita replacement parts.

•Use only pneumatic tool oil specified in this man-

ual.

•Never connect tool to compressed air line where

the maximum allowable pressure of tool cannot be

exceeded by 10 %. Make sure that the pressure

supplied by the compressed air system does not

exceed the maximum allowable pressure of the

fastener driving tool. Set the air pressure initially to

the lower value of the recommended allowable

pressure.

•Do not attempt to keep the trigger contact element

depressed with tape or wire. Death or serious

injury may occur.

•Always check contact element as instructed in this

manual. Nails may be driven accidentally if the

safety mechanism is not working correctly.

SAVE THESE INSTRUCTIONS.