5ENGLISH

prevent workpieces from "ringing".

4. Use appropriate hearing protection.

5. Operate and maintain the tool as recom-

mended in these instructions, to prevent an

unnecessary increase in noise levels.

6. Take noise reduction measures, for exam-

ple placing workpieces on sound damping

supports.

Vibration hazards

1. The vibration emission during operation

depends on the gripping force, the contact

pressure force, the working direction, the

adjustment of energy supply, the workpiece,

the workpiece support. Conduct a risk assess-

ment regarding vibration hazards and imple-

ment appropriate controls for these hazards.

2. Exposure to vibration can cause disabling

damage to the nerves and blood supply of the

hands and arms.

3. Wear warm clothing when working in cold

conditions, keep your hands warm and dry.

4. If you experience numbness, tingling, pain or

whitening of the skin in your ngers or hands,

seek medical advice from a qualied occupa-

tional health professional regarding overall

activities.

5. Operate and maintain the tool as recom-

mended in these instructions, to prevent an

unnecessary increase in vibration levels.

6. Hold the tool with a light, but safe, grip

because the risk from vibration is generally

greater when the grip force is higher.

Additional safety instructions for gas tools

1. Use the tool only with the Makita genuine gas

container.

2. Be careful when using gas tools, as the tool

can become hot, affecting grip and control.

3. Gas fastener driving tools shall be used in

ventilated spaces.

4. In the case that liquid combustible gas comes

into contact with human skin, injuries may

occur.

5. Gas containers shall be marked according to

the required transport regulation.

6. Handle gas containers carefully and check

for damages. Damaged gas containers can

explode and cause injury.

7. Read and follow the instructions supplied with

the gas container.

8. Ensure combustible materials are not exposed

to hot exhaust gases.

9. Do not use gas tools in explosive areas as the

sparks generated in the tool may cause re or

explosion.

10. Gas containers should not be stored care-

lessly or at high temperature. Follow the local

regulations and gas container's instructions

for handling and disposal of gas containers

and batteries or accumulators.

11. For gas tools, a small release of gas might be

generated by regular operations.

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

2. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

4. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If con-

tact accidentally occurs, ush with water. If

liquid contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause

irritation or burns.

5. Do not use a battery pack or tool that is dam-

aged or modied. Damaged or modied batteries

may exhibit unpredictable behaviour resulting in

re, explosion or risk of injury.

6. Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or tem-

perature above 130 °C may cause explosion.

7. Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specied in the instruc-

tions. Charging improperly or at temperatures

outside the specied range may damage the

battery and increase the risk of re.

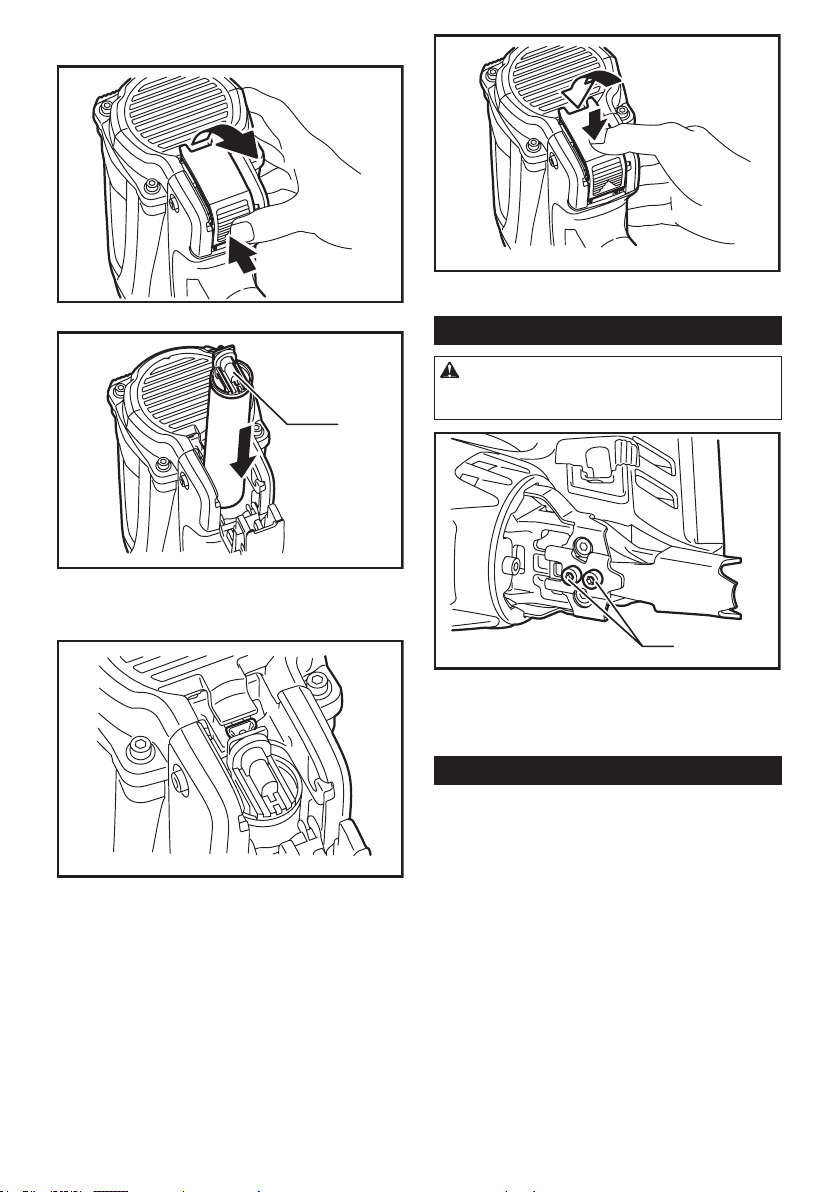

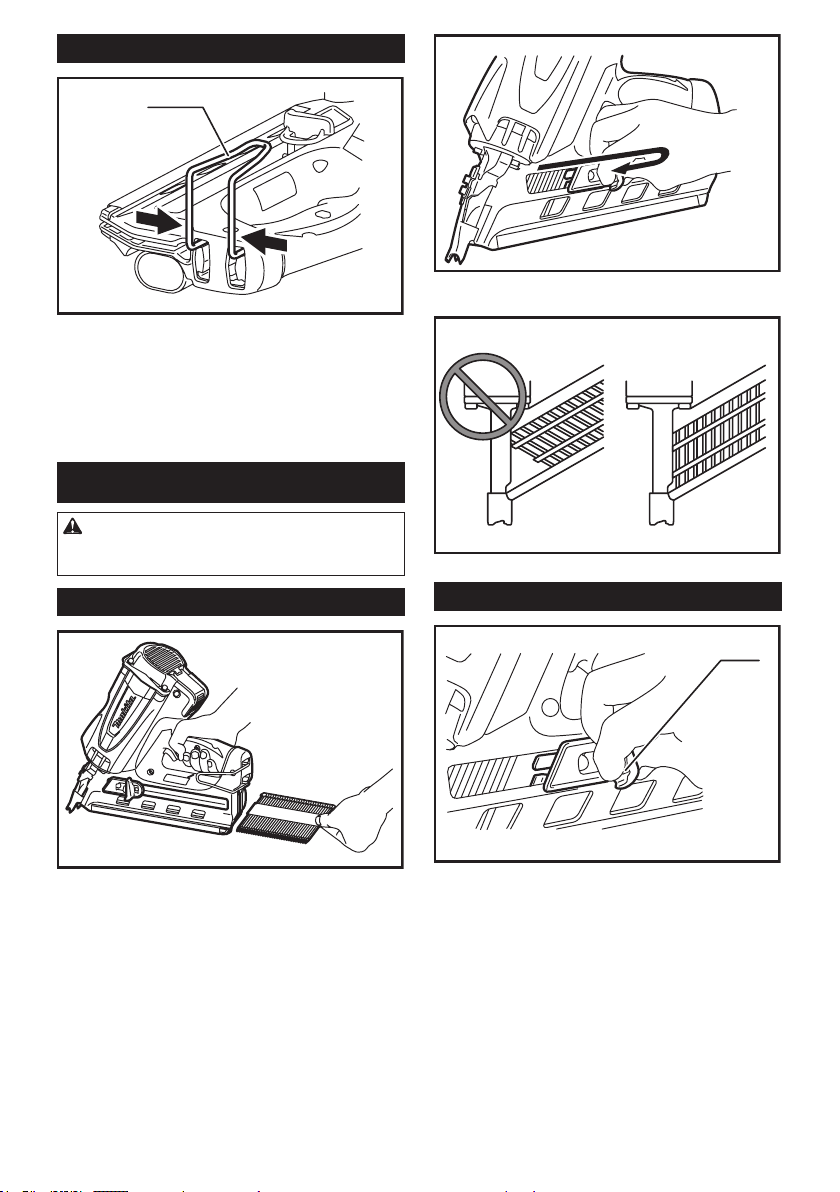

Safety devices

1. Make sure all safety systems are in working

order before operation. The tool must not oper-

ate if only the trigger is pulled or if only the contact

arm is pressed against the wood. It must work only

when both actions are performed. Test for possible

faulty operation with fasteners unloaded and the

pusher in fully pulled position.

2. Securing the trigger in the ON position is very

dangerous. Never attempt to fasten the trigger.

3. Do not attempt to keep the contact element

depressed with tape or wire. Death or serious

injury may occur.

4. Always check contact element as instructed

in this manual. Fasteners may be driven acci-

dentally if the safety mechanism is not working

correctly.

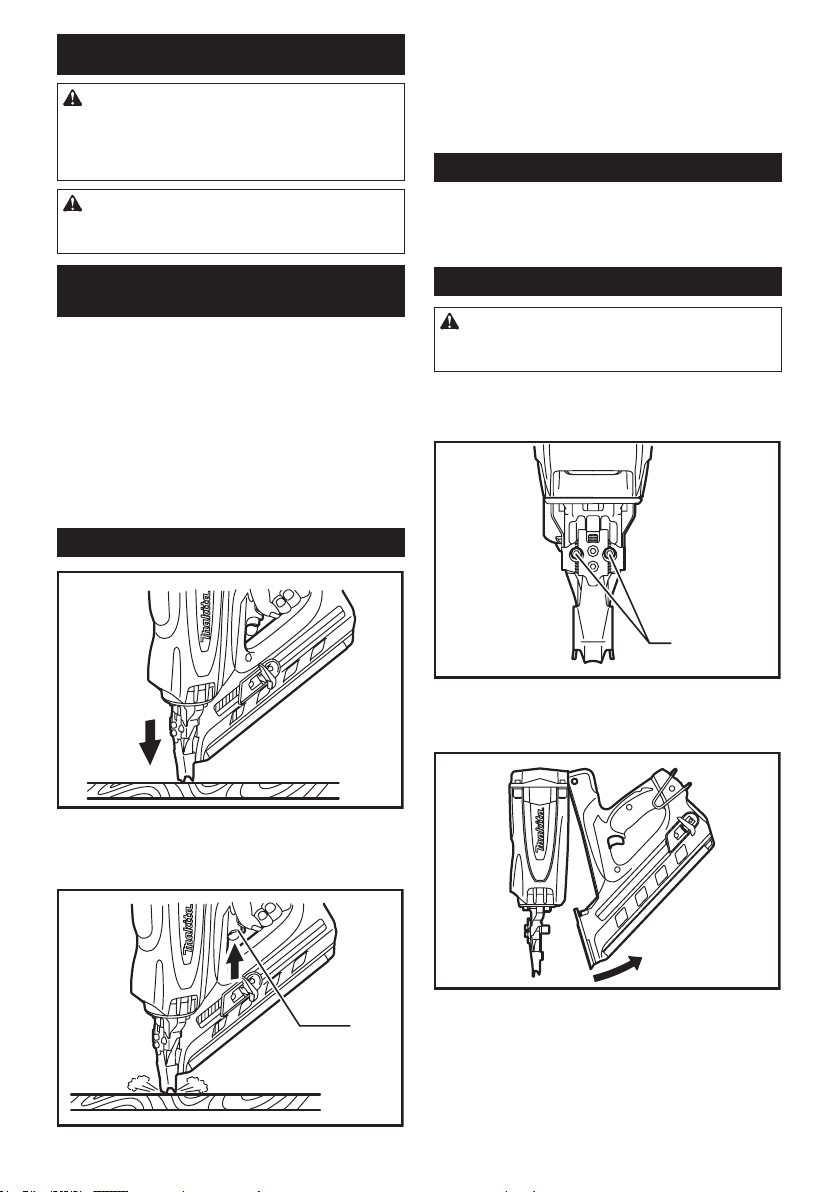

Service

1. Perform cleaning and maintenance right after

nishing the job. Keep the tool in tip-top condi-

tion. Lubricate moving parts to prevent rusting and

minimize friction-related wear. Wipe off all dust

from the parts.

2. Ask Makita authorized service center for peri-

odical inspection of the tool.

3. To maintain product SAFETY and RELIABILITY,

maintenance and repairs should be performed

by Makita Authorized Service Centers, always

using Makita replacement parts.

4. Follow local regulations when disposing of the

tool.

SAVE THESE INSTRUCTIONS.