Makita BPT350 Manual

Other Makita Nail Gun manuals

Makita

Makita AN923 User manual

Makita

Makita AN510H User manual

Makita

Makita AN711H User manual

Makita

Makita GF600 User manual

Makita

Makita AG125 User manual

Makita

Makita GN900 User manual

Makita

Makita AN635H User manual

Makita

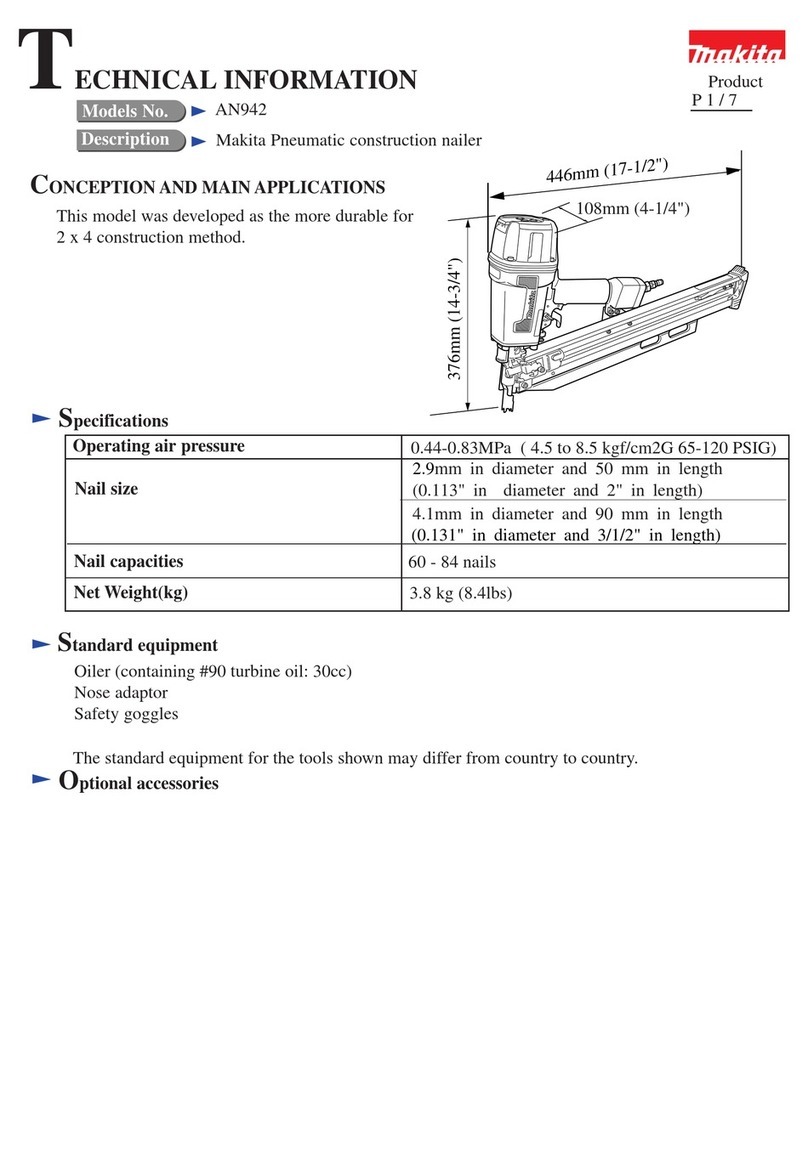

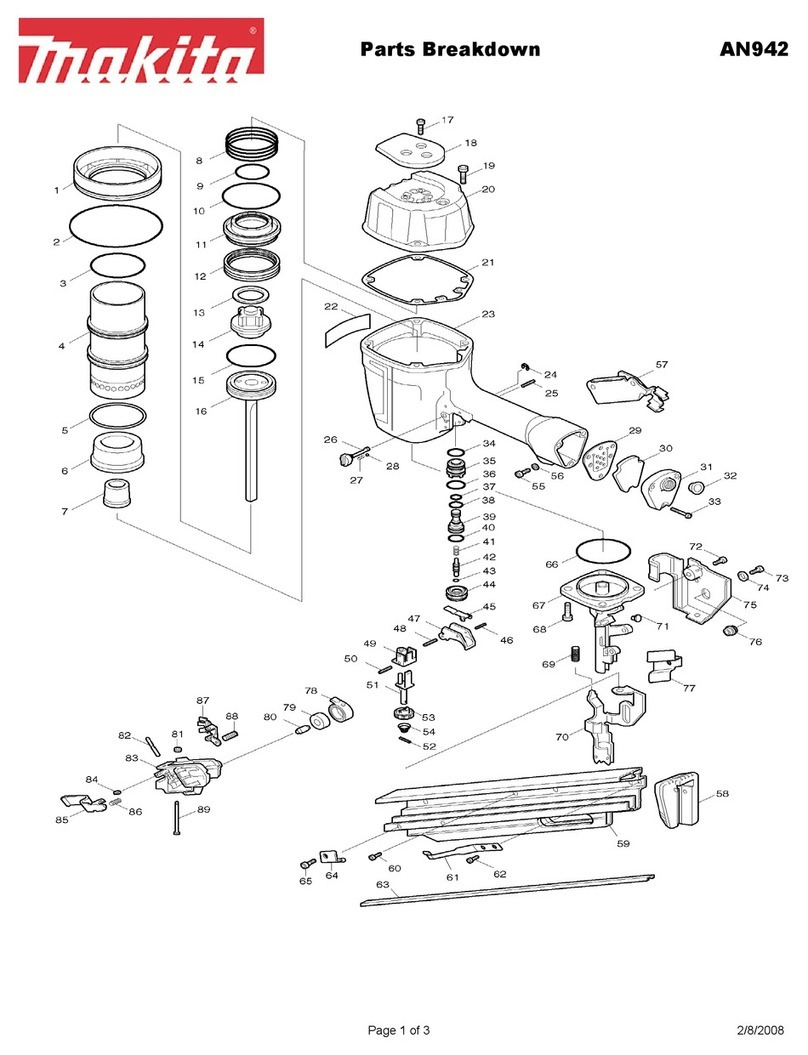

Makita AN942 Manual

Makita

Makita AN911H User manual

Makita

Makita AN942 Quick start guide

Makita

Makita AN935H User manual

Makita

Makita DFN350RFJ User manual

Makita

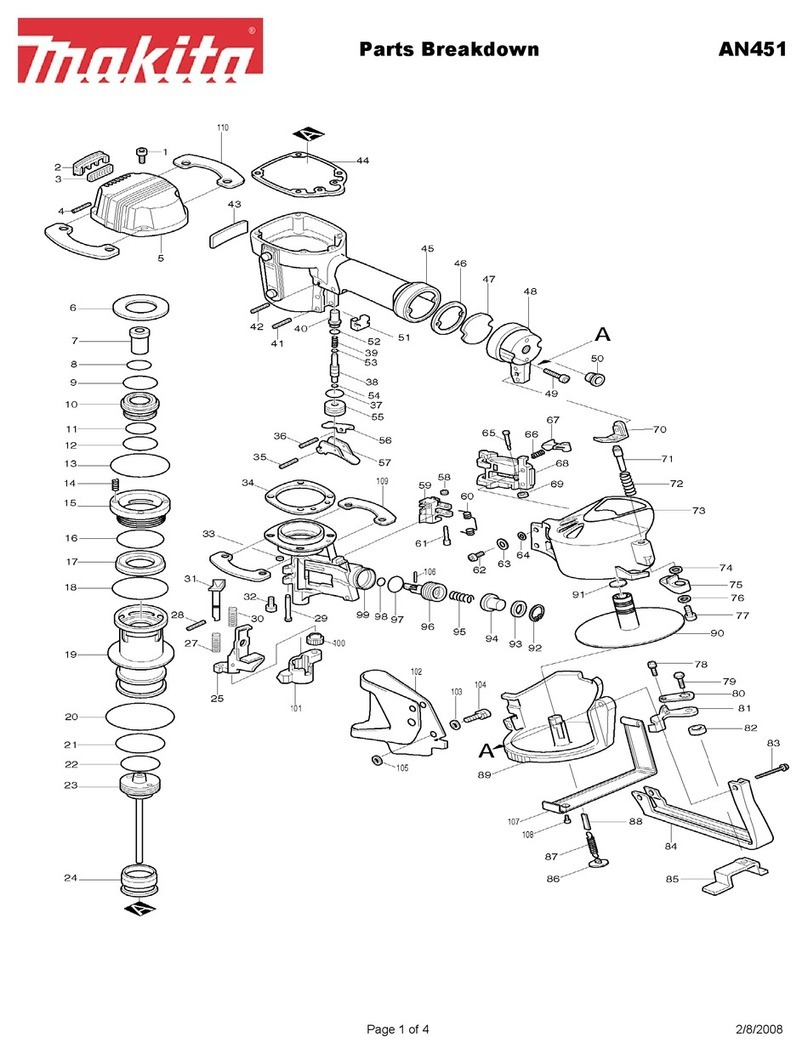

Makita AN451 Quick start guide

Makita

Makita AN902 User manual

Makita

Makita BPT350 User manual

Makita

Makita AN454 User manual

Makita

Makita AN923 User manual

Makita

Makita AF353 User manual

Makita

Makita AN8300 User manual

Makita

Makita DBN600 Operating instructions

Popular Nail Gun manuals by other brands

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes

Senco

Senco Fusion Technology F-35XP operating instructions

Grizzly

Grizzly G1847 instruction manual

Ryobi

Ryobi R18N18G Original instructions

Black & Decker

Black & Decker 492848-00 instruction manual

HOLZMANN MASCHINEN

HOLZMANN MASCHINEN TN90 user manual

Metabo HPT

Metabo HPT NR 3690DC Instruction and safety manual

Surtek

Surtek CN650 User manual and warranty

Parkside

Parkside PET 25 B1 Operation and safety notes

Senco

Senco AirFree 25 operating instructions