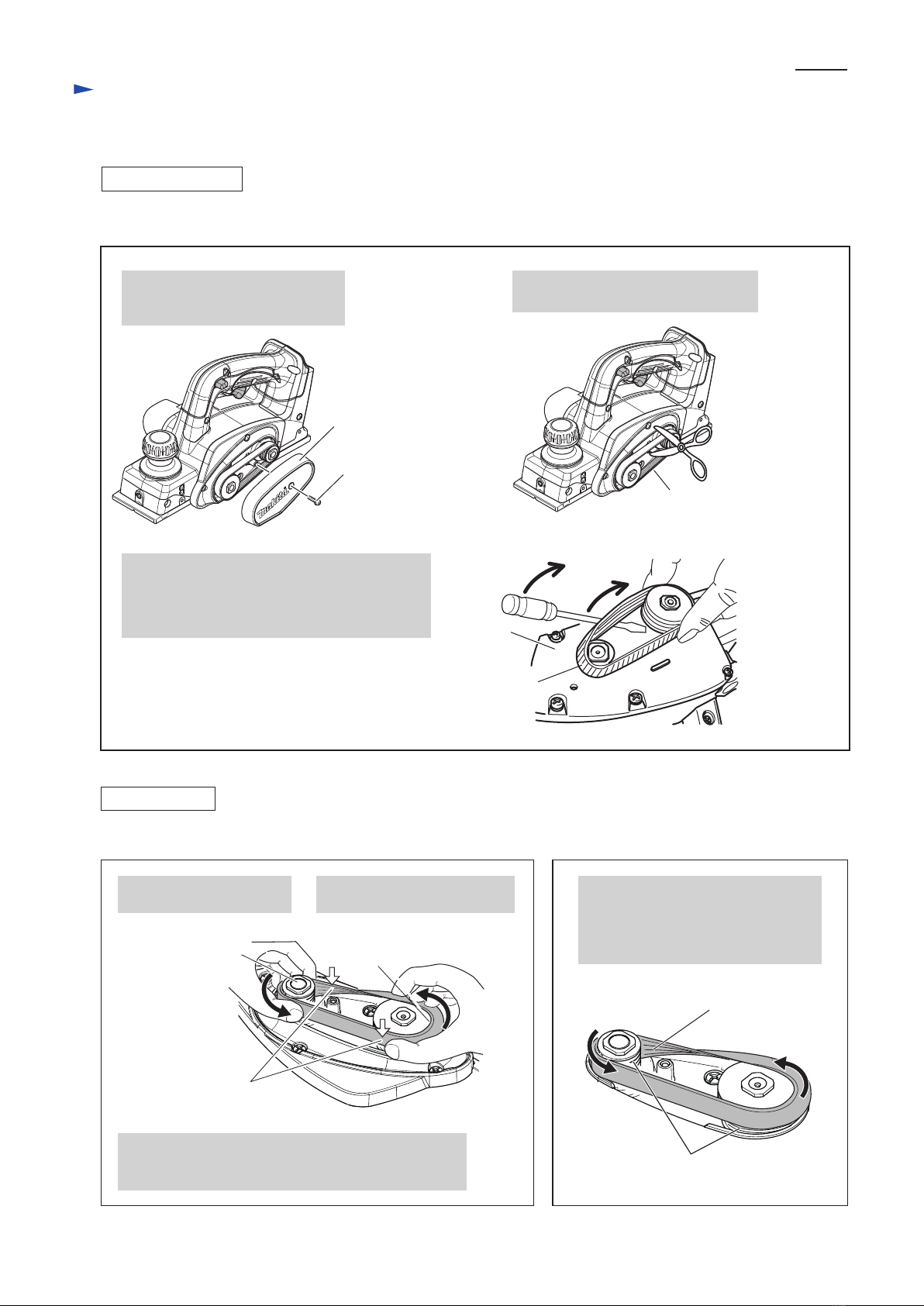

Makita BKP180Z Manual

Other Makita Planer manuals

Makita

Makita DKP140 User manual

Makita

Makita 1806B User manual

Makita

Makita KP001G User manual

Makita

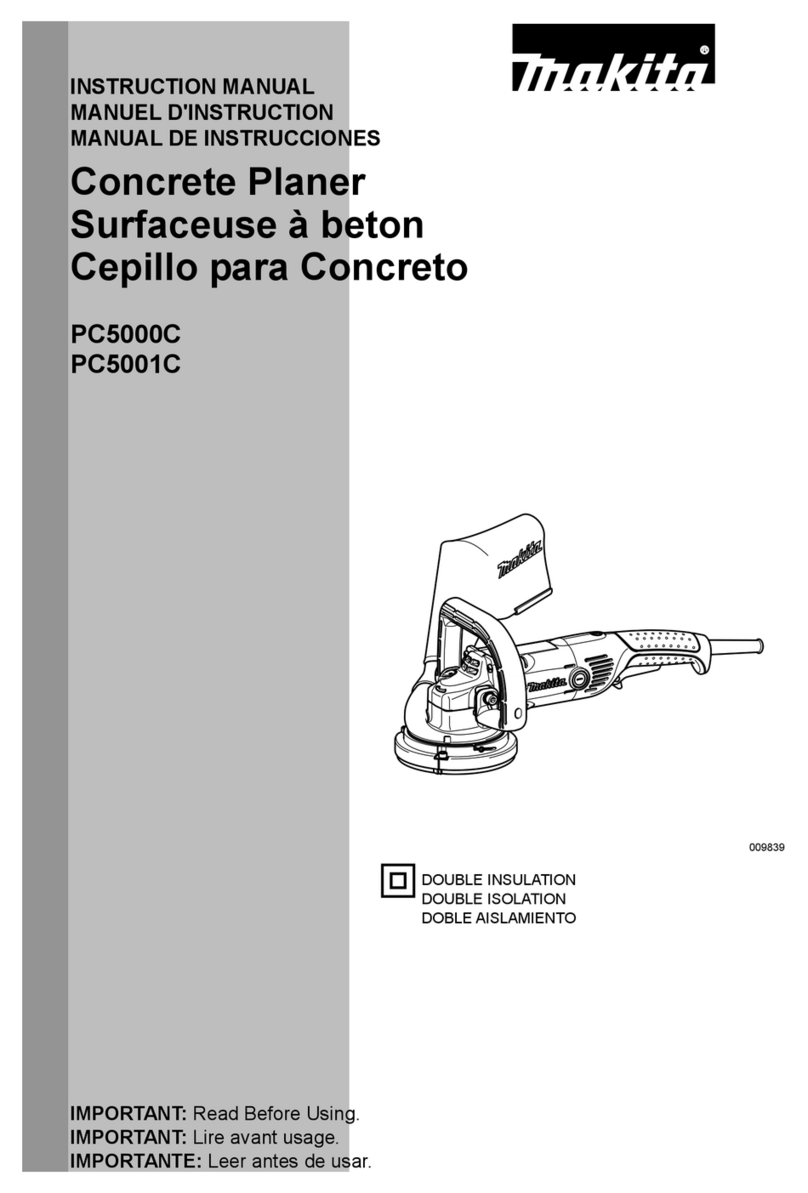

Makita PC5000C User manual

Makita

Makita DKP181Z User manual

Makita

Makita 2030N User manual

Makita

Makita 1923B User manual

Makita

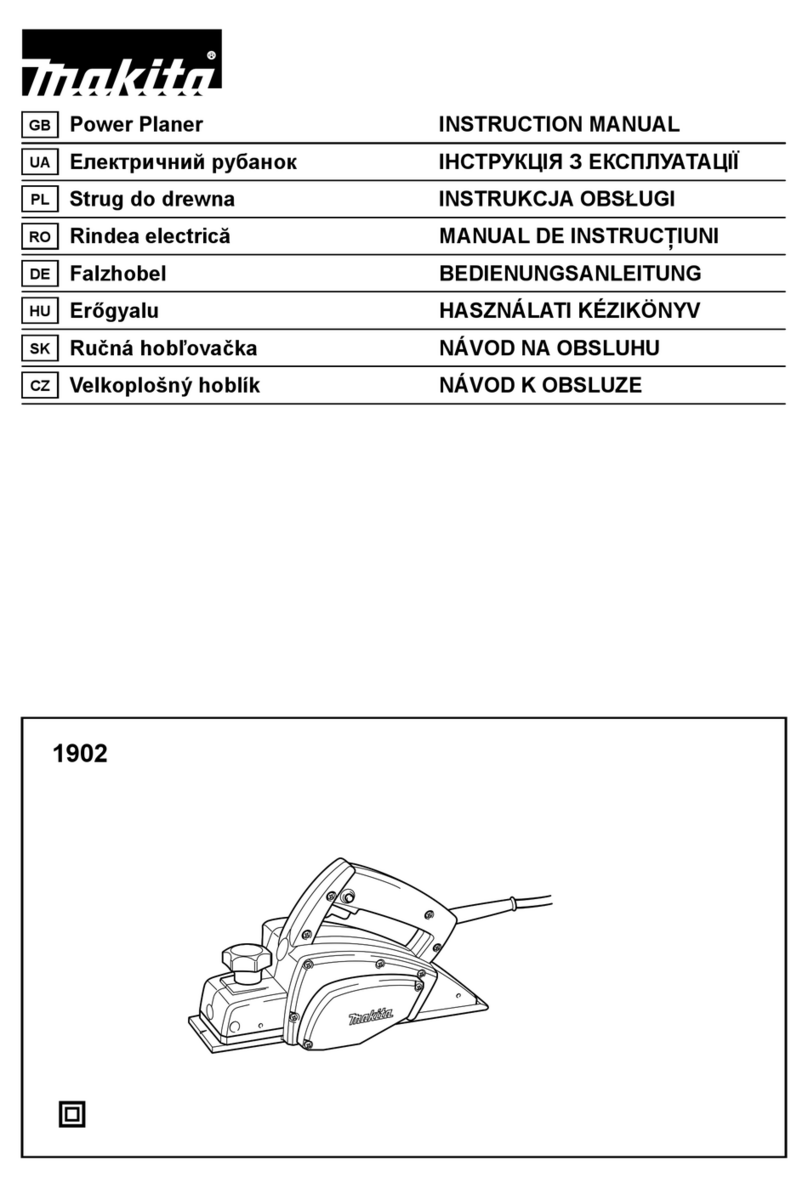

Makita 1902 User manual

Makita

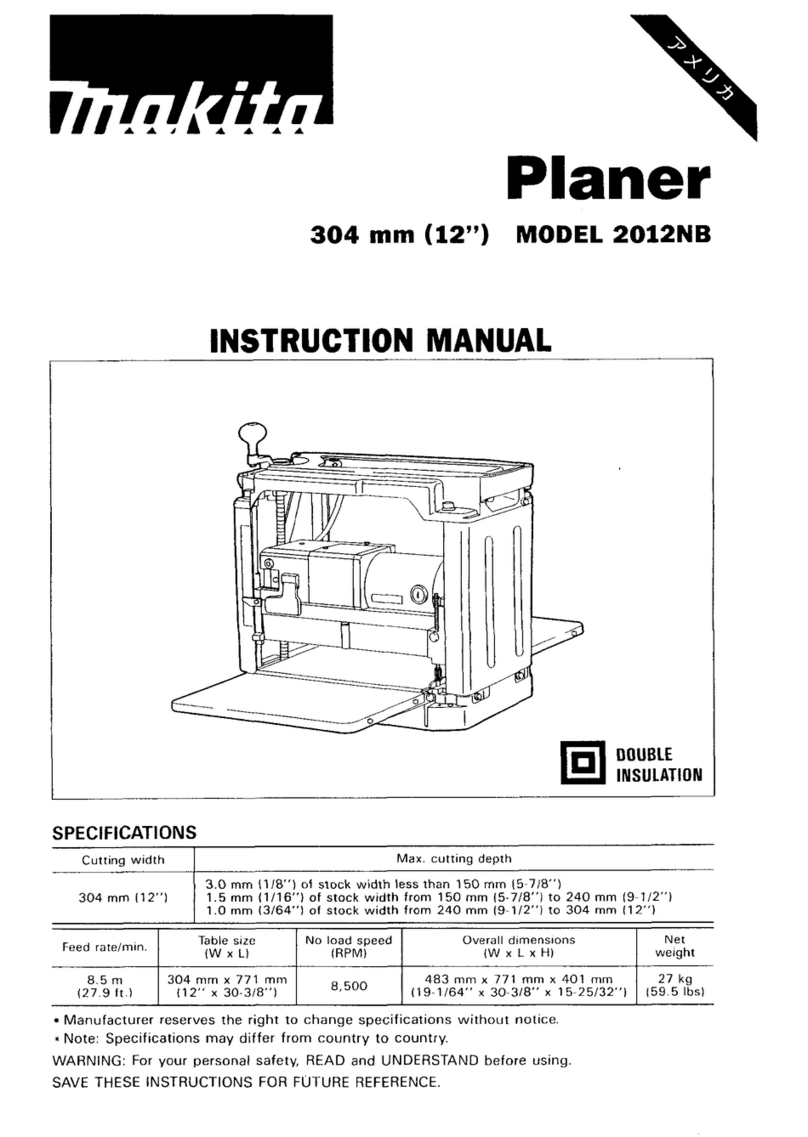

Makita 2012NB User manual

Makita

Makita M1902 User manual

Makita

Makita KP001G User manual

Makita

Makita KP0800/2 User manual

Makita

Makita KP312 User manual

Makita

Makita BKP180RFJ User manual

Makita

Makita M1902 User manual

Makita

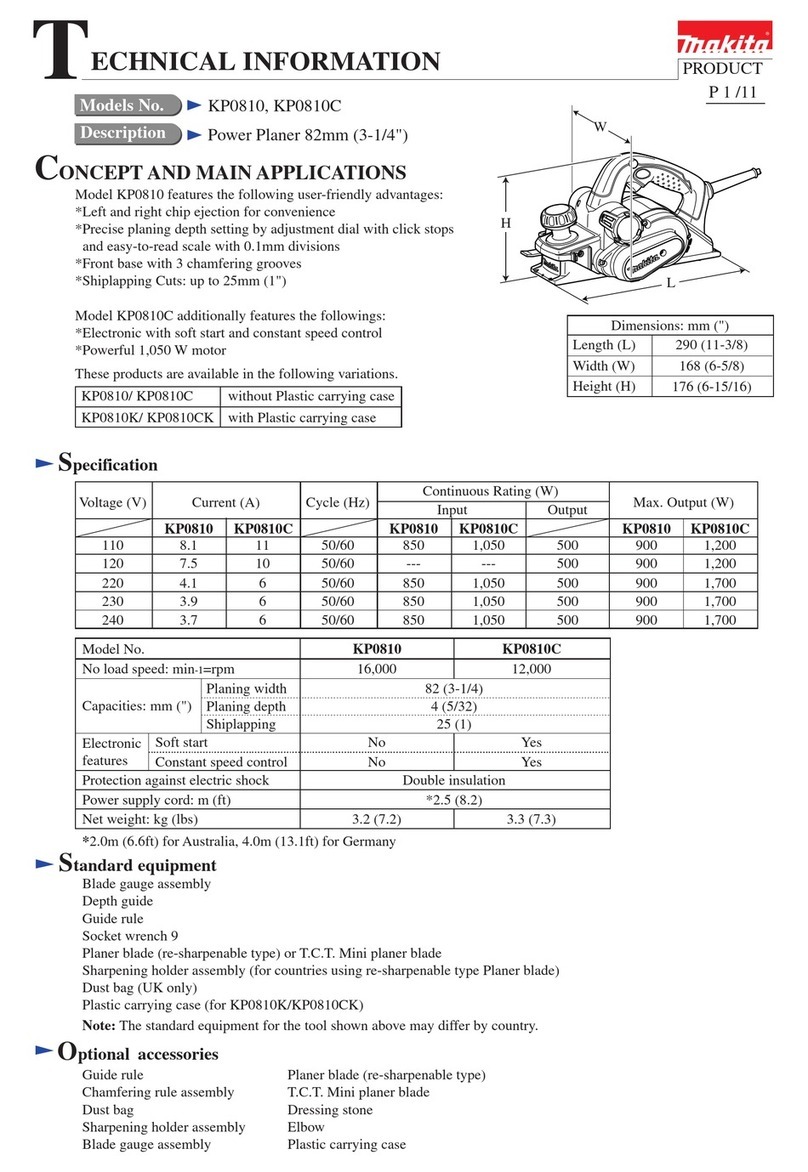

Makita KP0810 User manual

Makita

Makita 2012NB/2 User manual

Makita

Makita 2012NB User manual

Makita

Makita PC5000C User manual

Makita

Makita KP0810 Manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual