1INDEX

1INDEX.......................................................................................................................................................................................... 2

2CAUTION .................................................................................................................................................................................... 3

3NECESSARY REPAIRING TOOLS ........................................................................................................................................... 3

4LUBRICANT AND ADHESIVE APPLICATION ...................................................................................................................... 3

5REPAIR ........................................................................................................................................................................................ 4

5-1 Poly V-belt 4-241 ................................................................................................................................................................. 4

5-1-1 Disassembling ............................................................................................................................................................. 4

5-1-2 Assembling.................................................................................................................................................................. 5

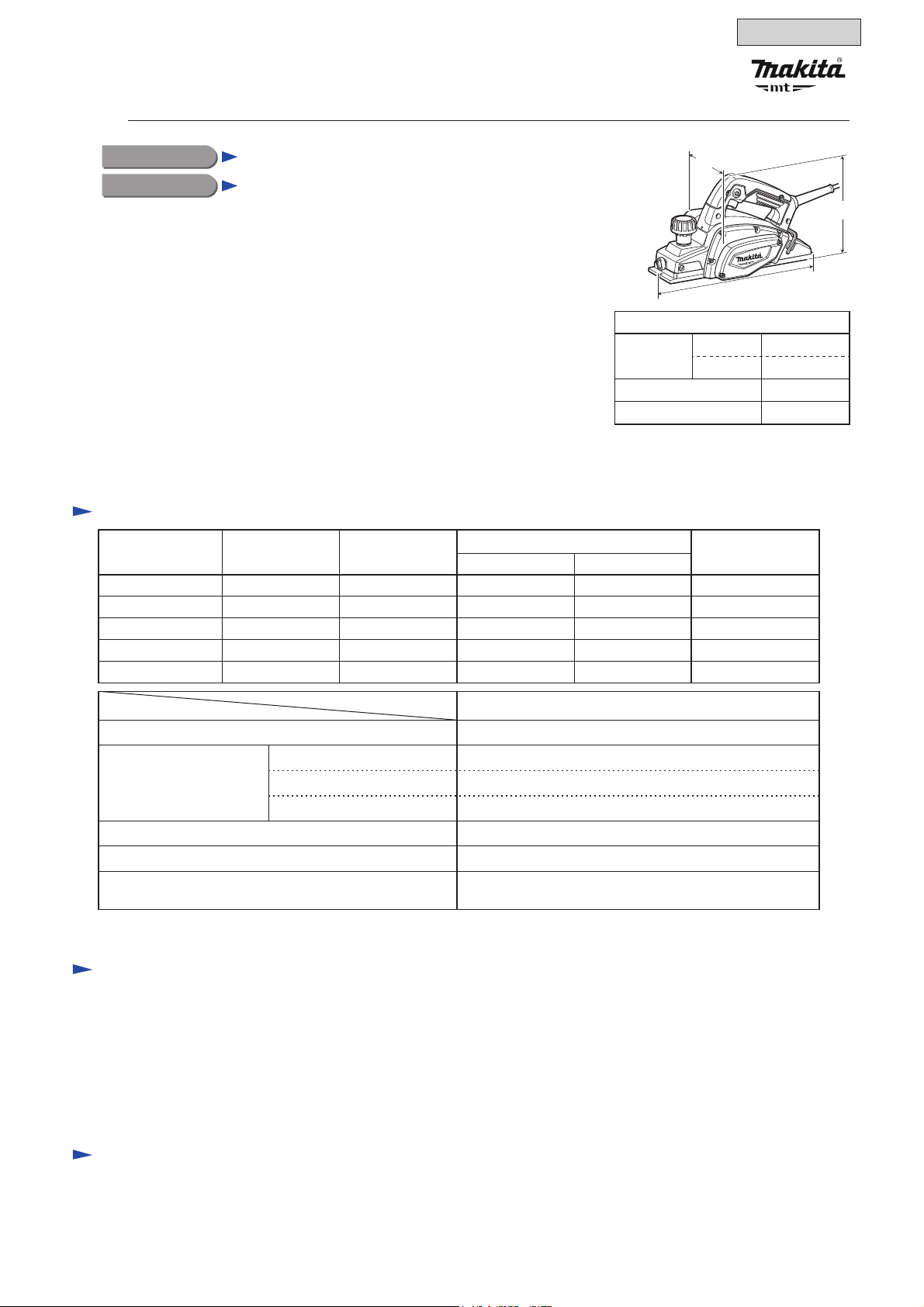

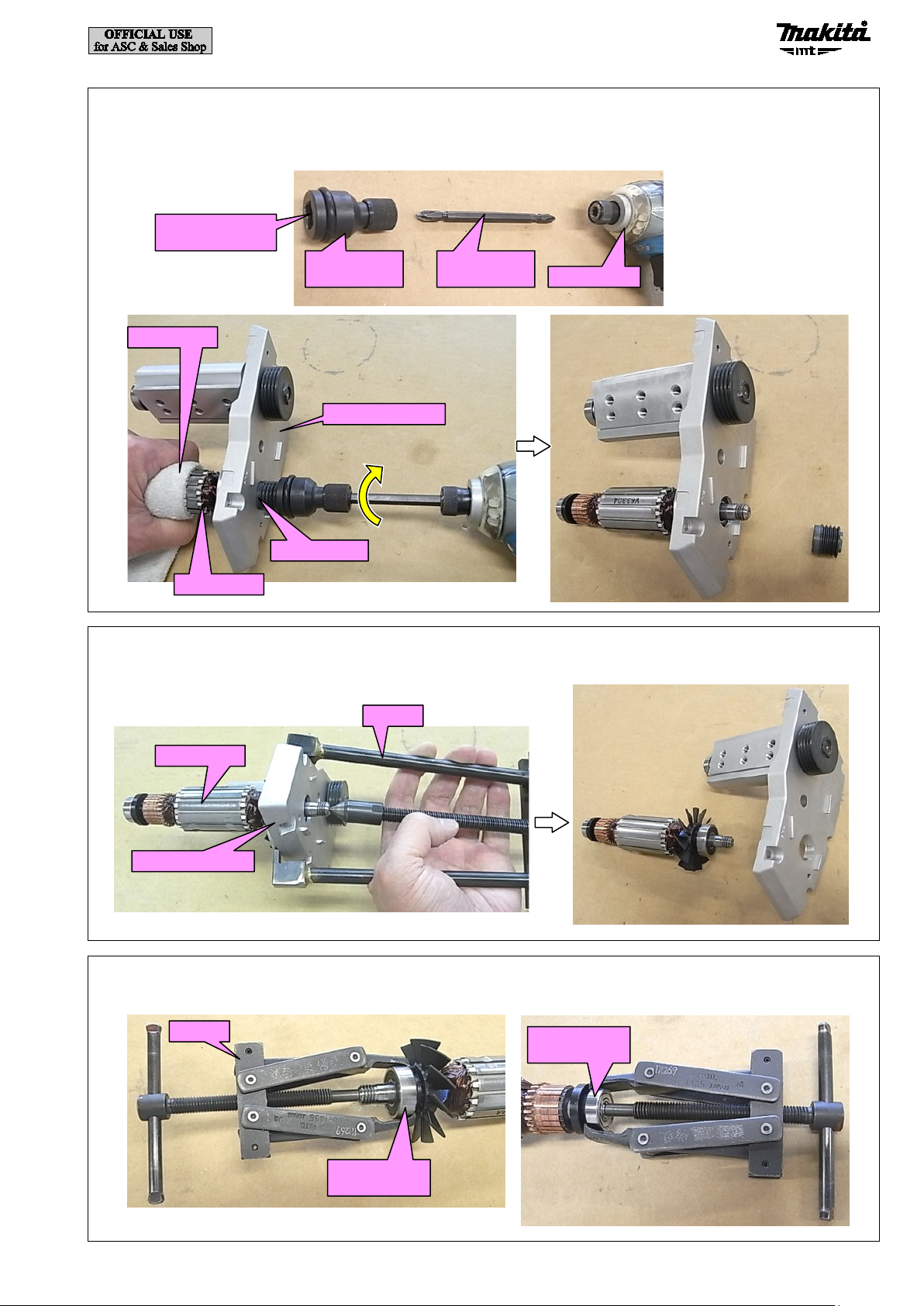

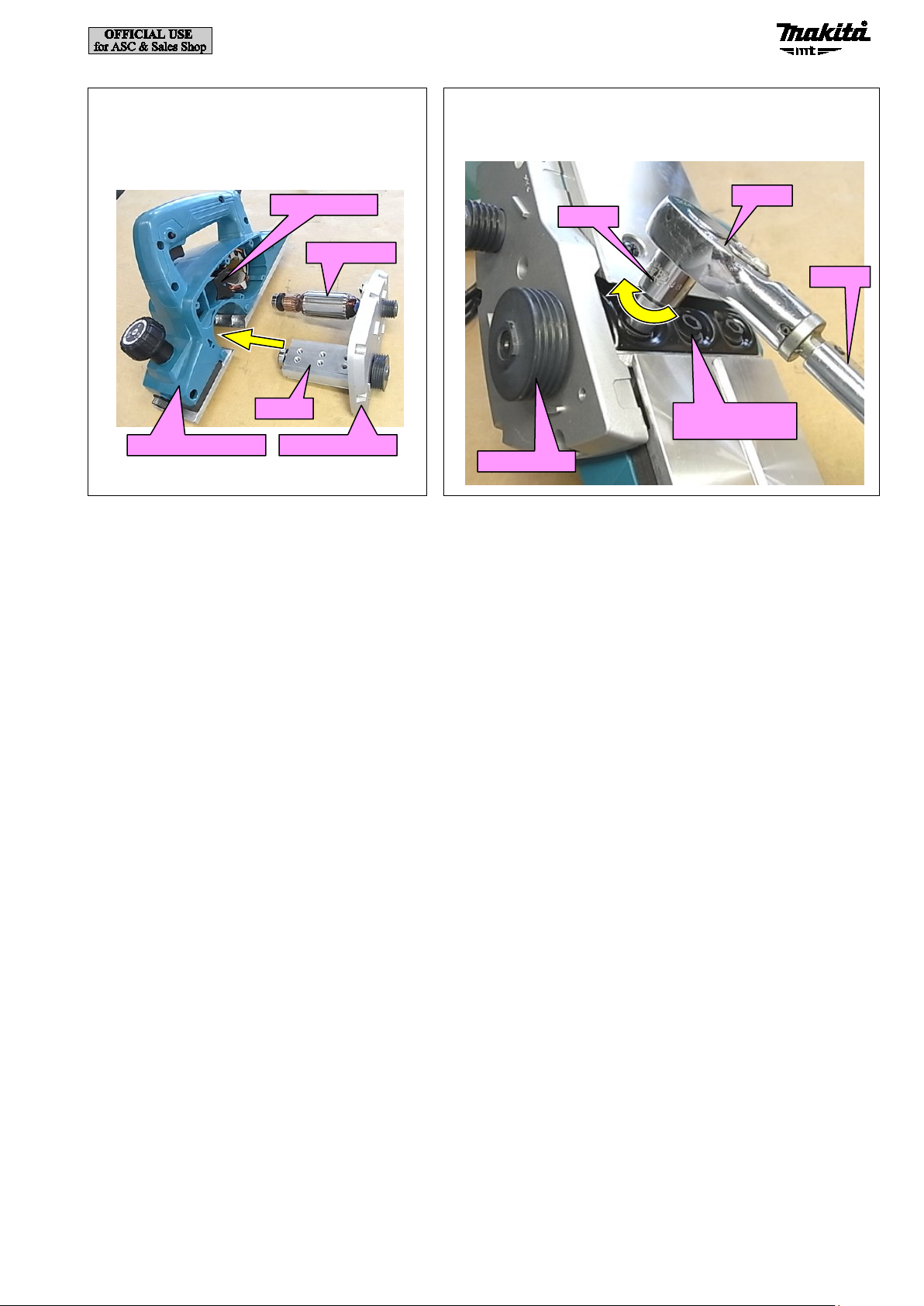

5-2 Armature .............................................................................................................................................................................. 6

5-2-1 Disassembling ............................................................................................................................................................. 6

5-2-2 Assembling.................................................................................................................................................................. 9

5-3 Drum .................................................................................................................................................................................. 11

5-3-1 Disassembling ........................................................................................................................................................... 11

5-3-2 Assembling................................................................................................................................................................ 12

5-4 Front base, Base ................................................................................................................................................................. 14

5-4-1 Disassembling ........................................................................................................................................................... 14

5-4-2 Assembling................................................................................................................................................................ 15

5-5 Foot .................................................................................................................................................................................... 15

5-5-1 Disassembling ........................................................................................................................................................... 15

5-5-2 Assembling................................................................................................................................................................ 15

6Circuit diagram ........................................................................................................................................................................... 16

7Wiring diagram ........................................................................................................................................................................... 17

8TIGHTENING TORQUE SPECIFICATIONS.......................................................................................................................... 19

2 / 19