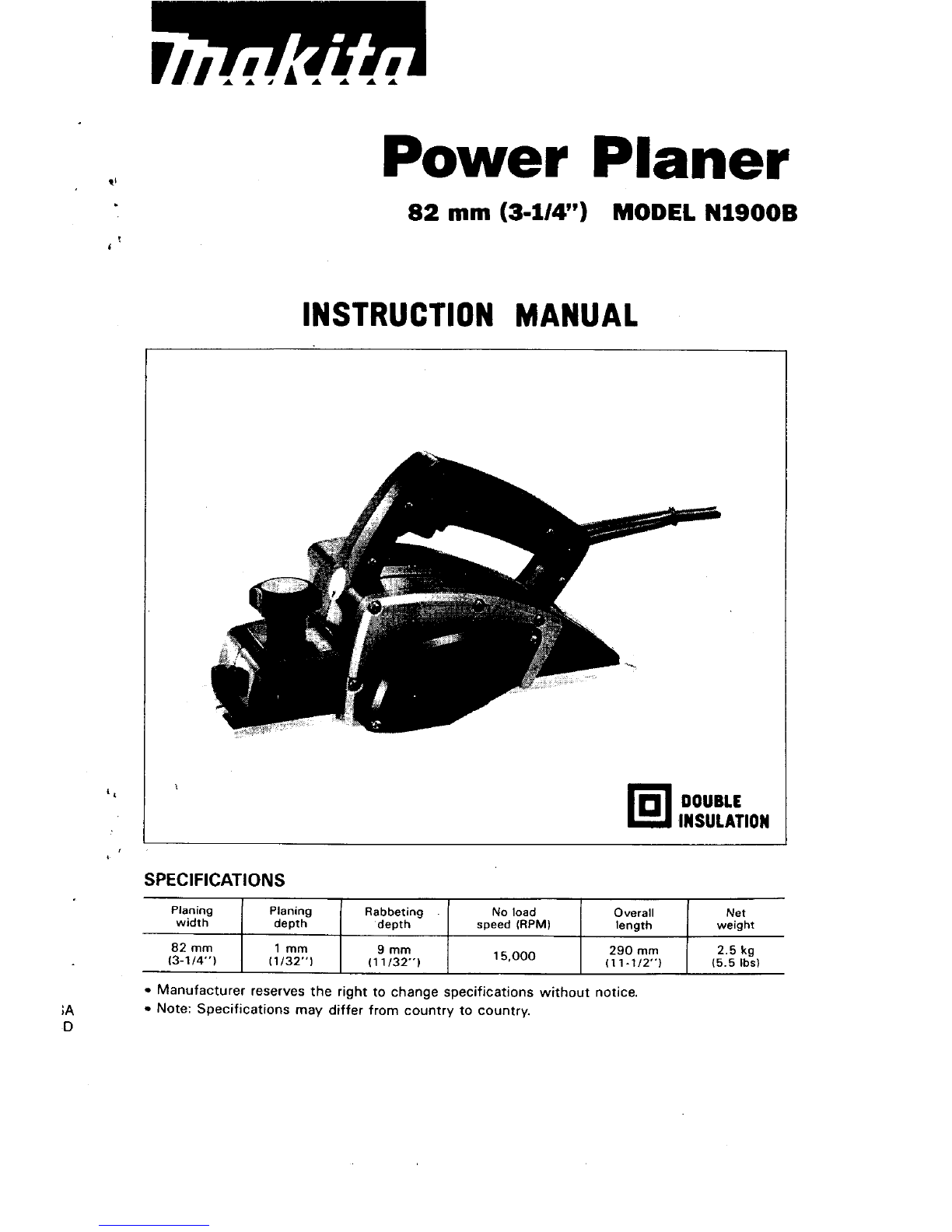

Makita N1900B User manual

Other Makita Planer manuals

Makita

Makita KP312 User manual

Makita

Makita HG 1100 User manual

Makita

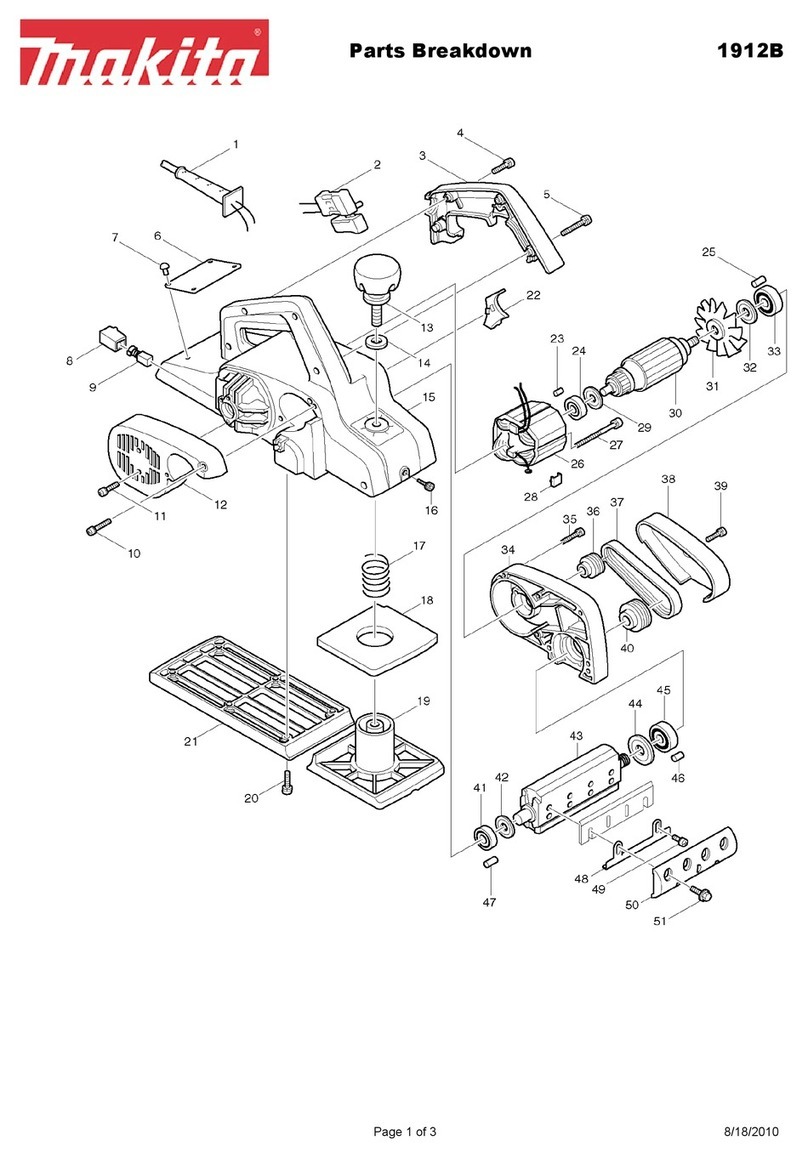

Makita 1912B Quick start guide

Makita

Makita M1901 User manual

Makita

Makita M1902 User manual

Makita

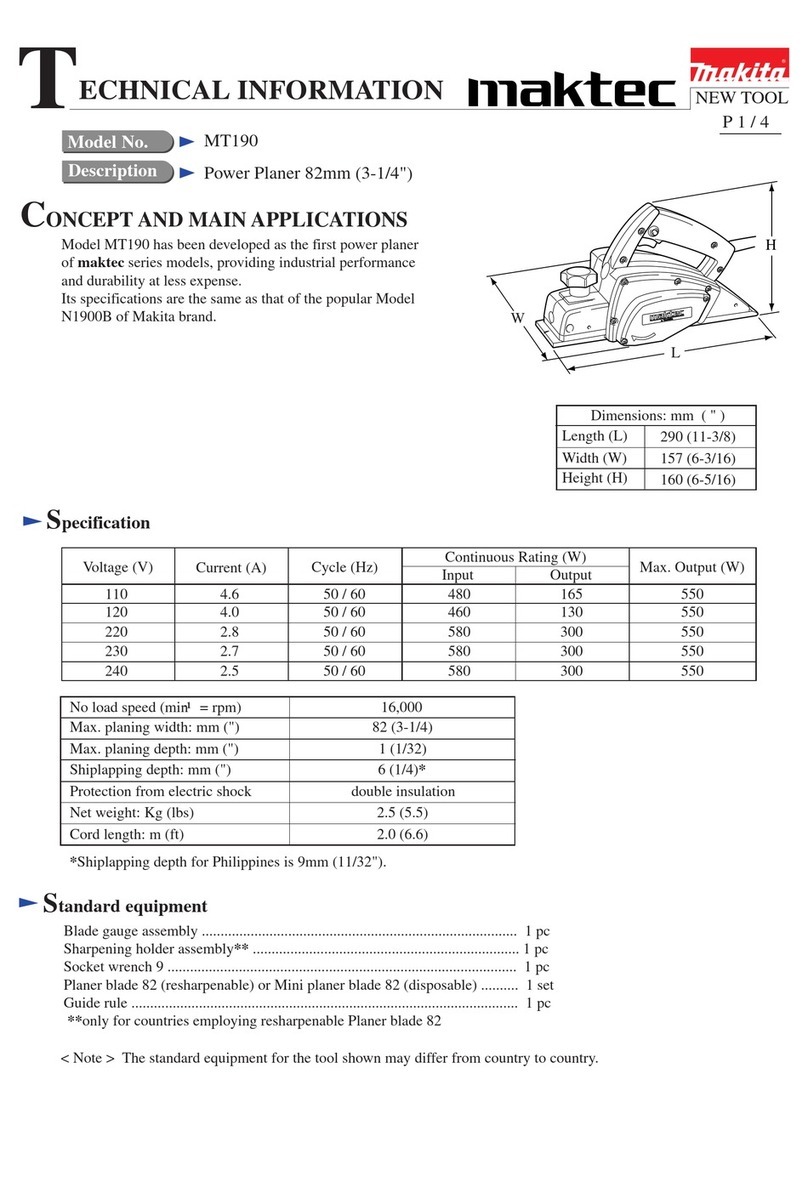

Makita Maktec MT190 Manual

Makita

Makita KP312 User manual

Makita

Makita KP312 User manual

Makita

Makita PC5000C User manual

Makita

Makita DKP140 User manual

Makita

Makita KP0810 User manual

Makita

Makita BKP140 User manual

Makita

Makita HG 1100 User manual

Makita

Makita 1911B User guide

Makita

Makita 2030S User manual

Makita

Makita 1050D User manual

Makita

Makita 1806B User manual

Makita

Makita 2012NB User manual

Makita

Makita M1902 User manual

Makita

Makita DKP181 User manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual