Makita PC5001C Manual

Other Makita Planer manuals

Makita

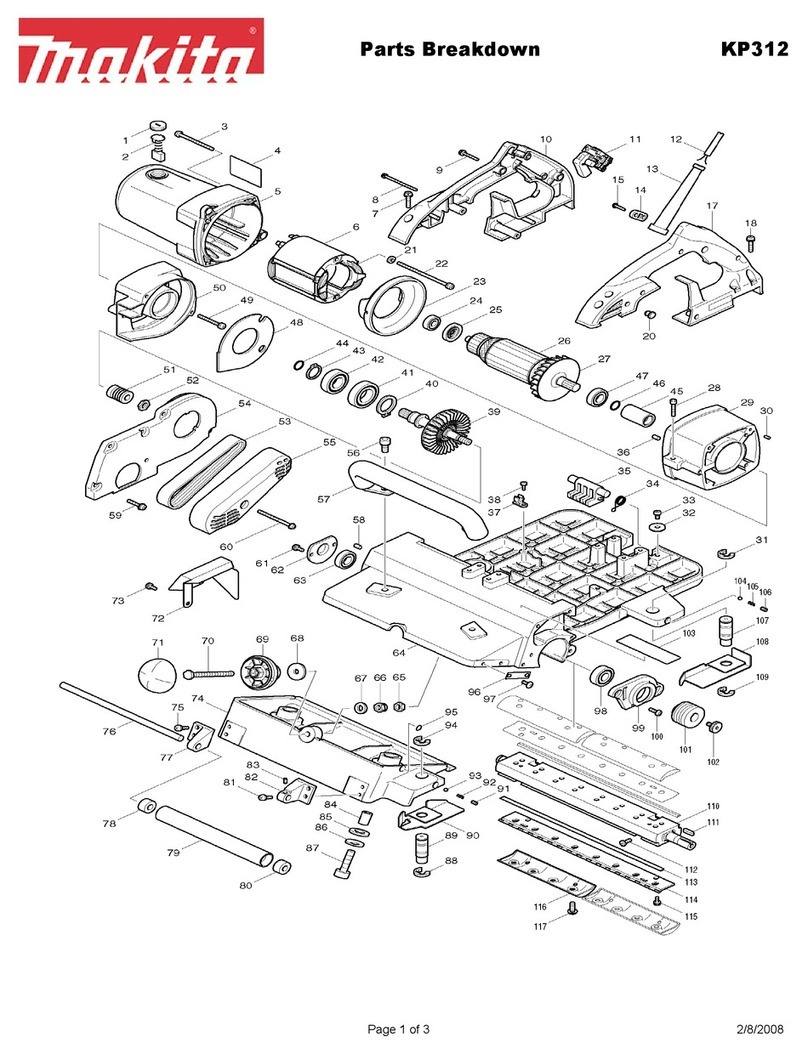

Makita KP312S User manual

Makita

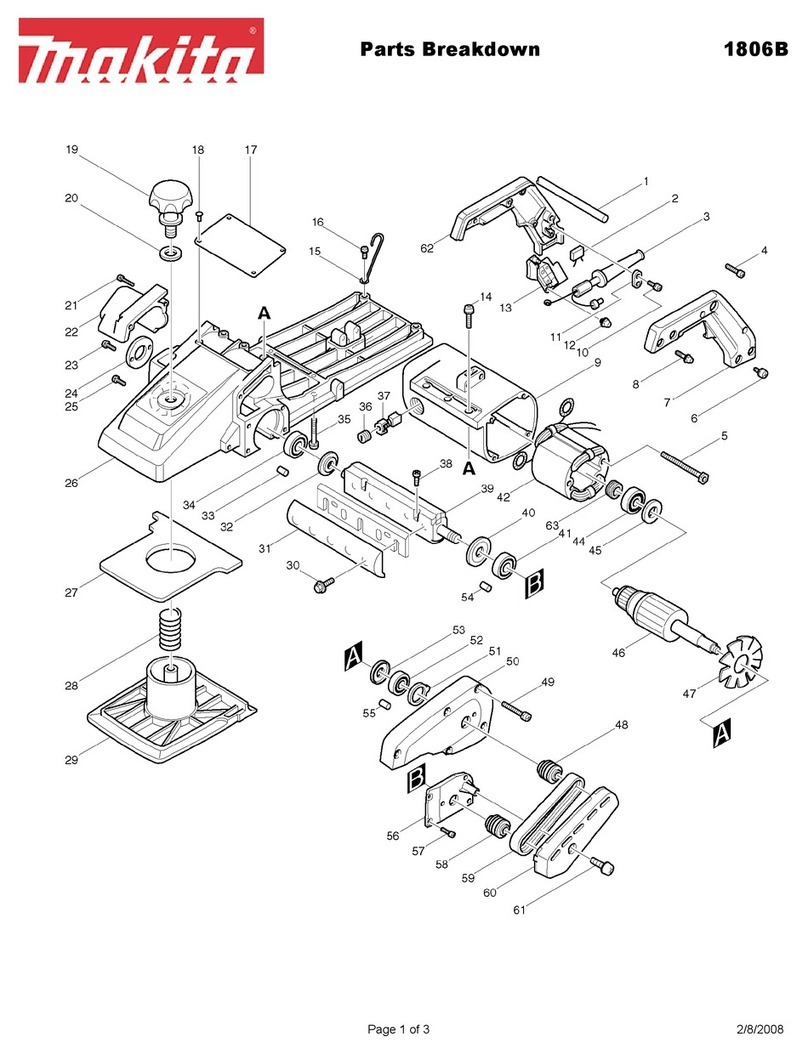

Makita 1806B Quick start guide

Makita

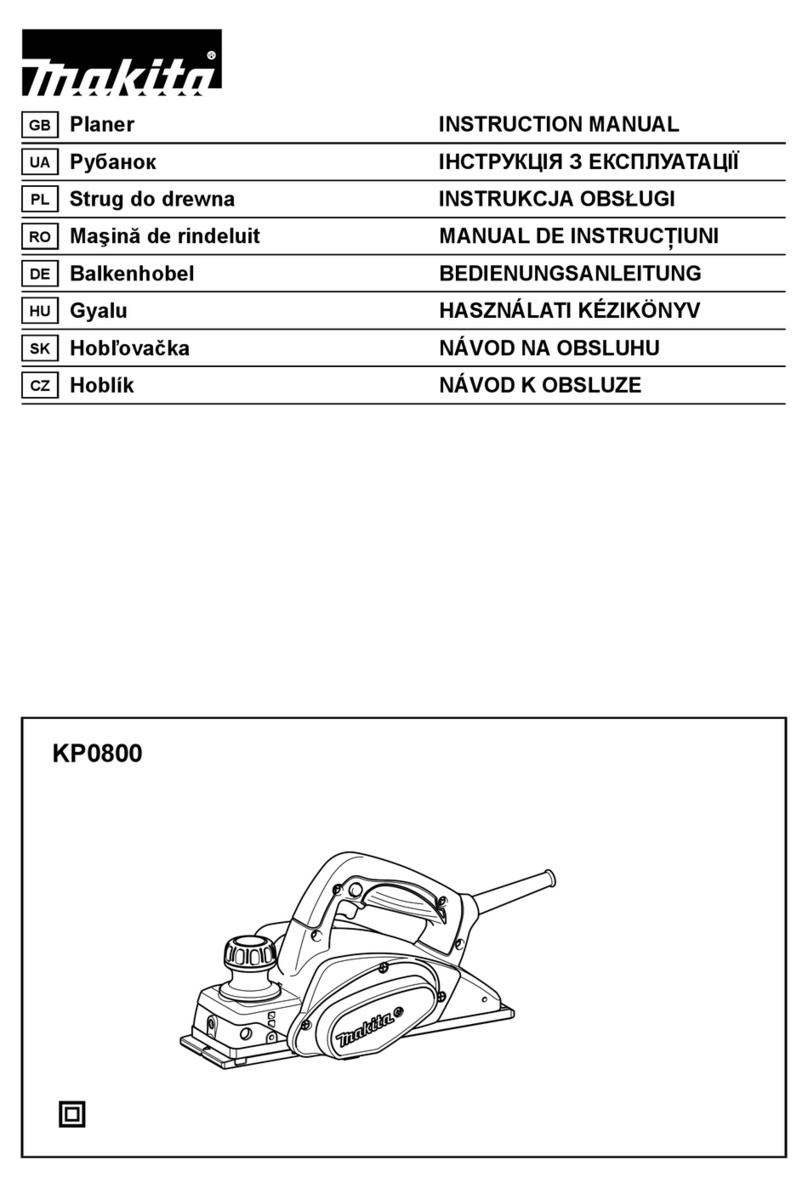

Makita KP0800 User manual

Makita

Makita HG 1100 User manual

Makita

Makita 1805B User manual

Makita

Makita PC5000C User manual

Makita

Makita KP312 Quick start guide

Makita

Makita KP312 User manual

Makita

Makita HG 1100 User manual

Makita

Makita 2012NB User manual

Makita

Makita 1911B User manual

Makita

Makita 1902 Quick start guide

Makita

Makita 1806B User manual

Makita

Makita PC1100 User manual

Makita

Makita LXPK01 User manual

Makita

Makita KP0800 Manual

Makita

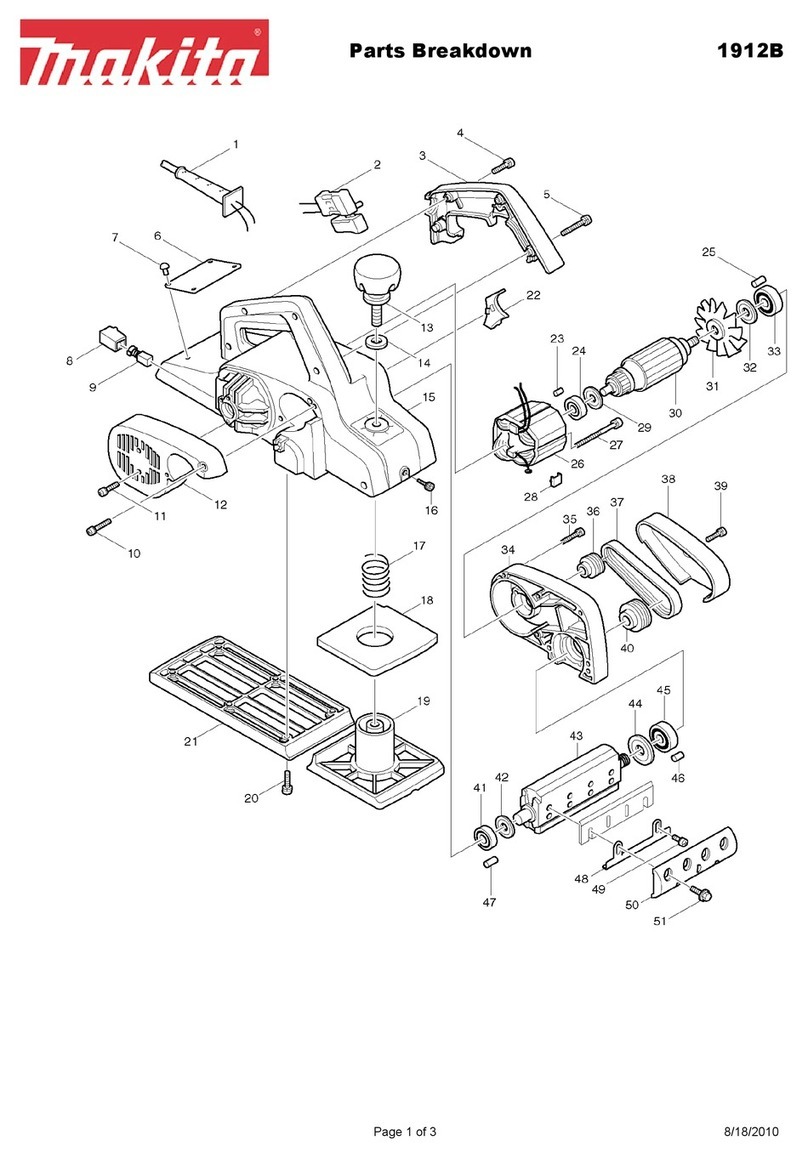

Makita 1912B Quick start guide

Makita

Makita KP0800 User manual

Makita

Makita 1912B User manual

Makita

Makita KP0810 User manual

Popular Planer manuals by other brands

Felisatti

Felisatti PF180/1500 operating instructions

DeWalt

DeWalt DW 1150 Operation, adjustmants, maintenance, spare parts

Triton

Triton TRP UL Operating and safety instructions

Melbourne

Melbourne MTC-49407 owner's manual

VARO

VARO POWERplus POW1520 manual

Powermatic

Powermatic 209 Operating instructions and parts manual