9ENGLISH

Installing cartridge

NOTICE:

• Make sure the piston A is attached to the rod. Do

not use other type of piston for cartridge.

Installing the cartridge into the short

holder (300ml)

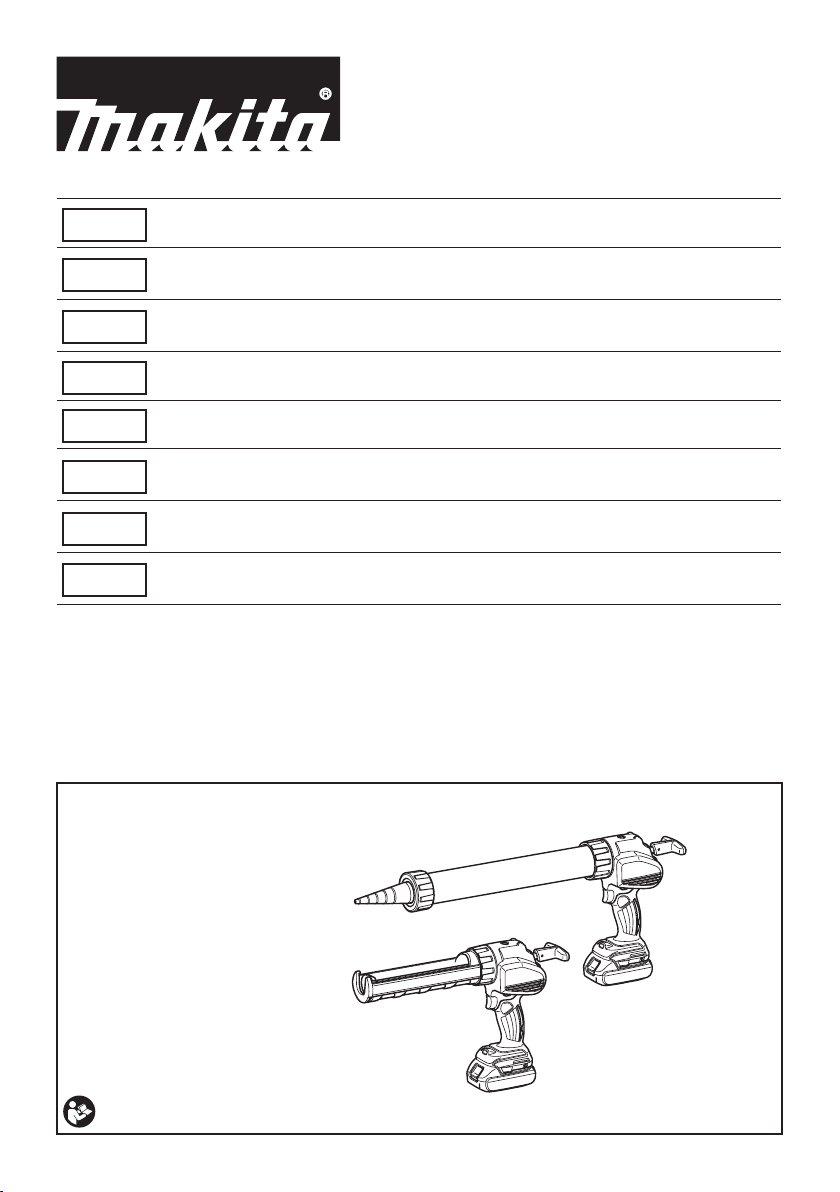

► Fig.13: 1. Rod handle

Pull the rod handle backwards slowly until it stops.

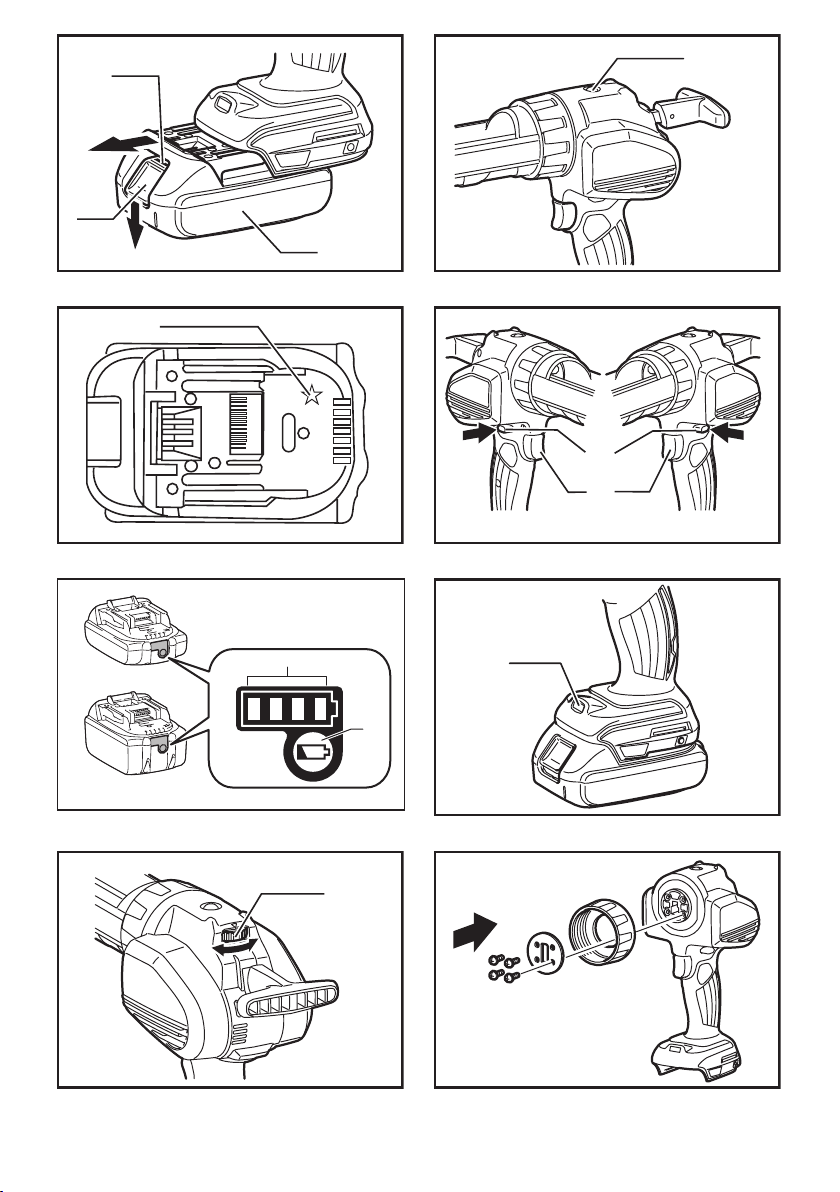

► Fig.14

Insert the cartridge into the holder as illustrated.

Push the rod gently until the piston touches the bottom

of the cartridge.

To remove the cartridge, pull the rod backwards until it

stops, then lift out the cartridge.

Installing the cartridge into the long

holder (600ml)

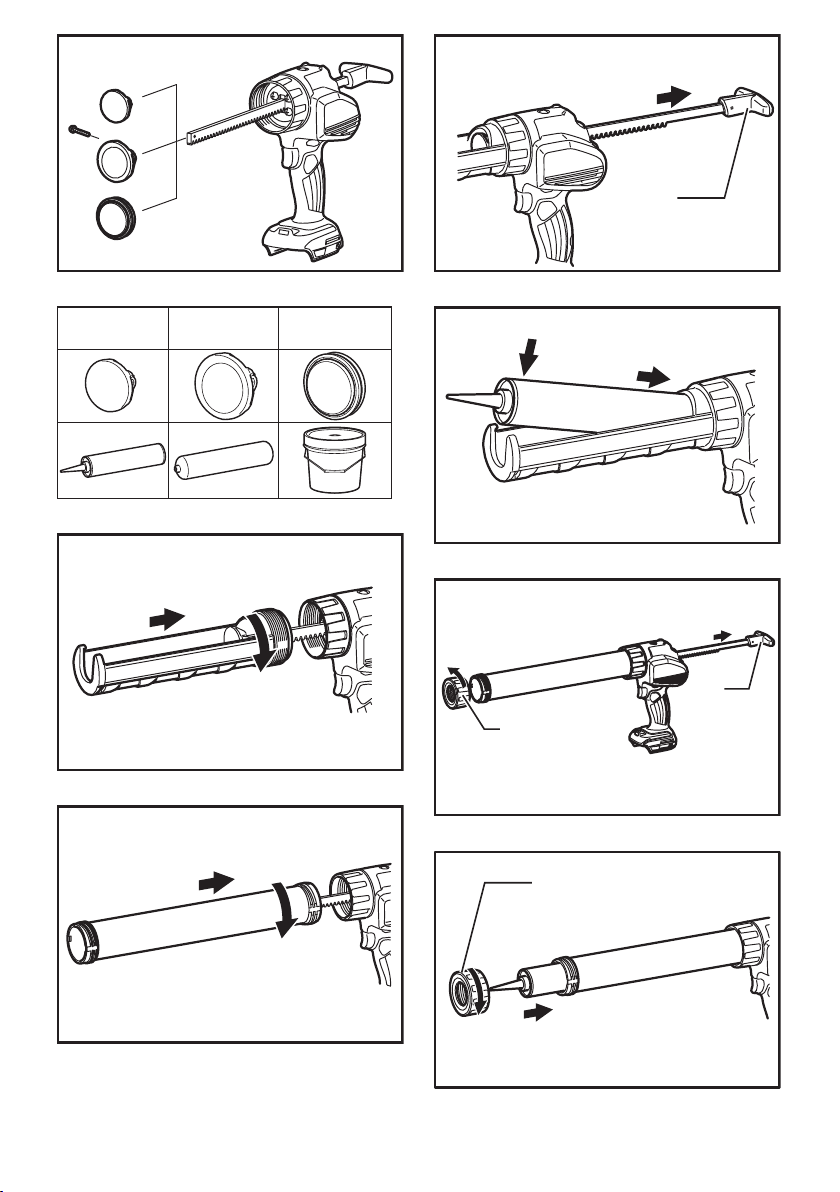

► Fig.15: 1. Holder cap 2. Rod handle

Remove the holder cap from the holder.

Pull the rod handle backwards slowly until it stops.

► Fig.16: 1. Holder cap

Insert the cartridge into the holder.

Attach the holder cap. Make sure it is tightened rmly.

Push the rod gently until the piston touches the bottom

of the cartridge.

To remove the cartridge, remove the holder cap, then

take out the cartridge.

NOTICE:

• Always check the cartridge for puncture or dam-

age before installing. Do not use damaged car-

tridge, otherwise the tool may be damaged.

• When using a partially used cartridge, remove any

adhered material on the cartridge.

Installing lm type pack

NOTICE:

• Make sure the piston B is attached to the rod. Do

not use other type of piston for lm type pack.

• Film type pack can be installed in the long holder

(600ml) only.

Remove the holder cap, the nozzle and the rubber ring

from the holder.

Pull the rod handle backwards slowly until it stops.

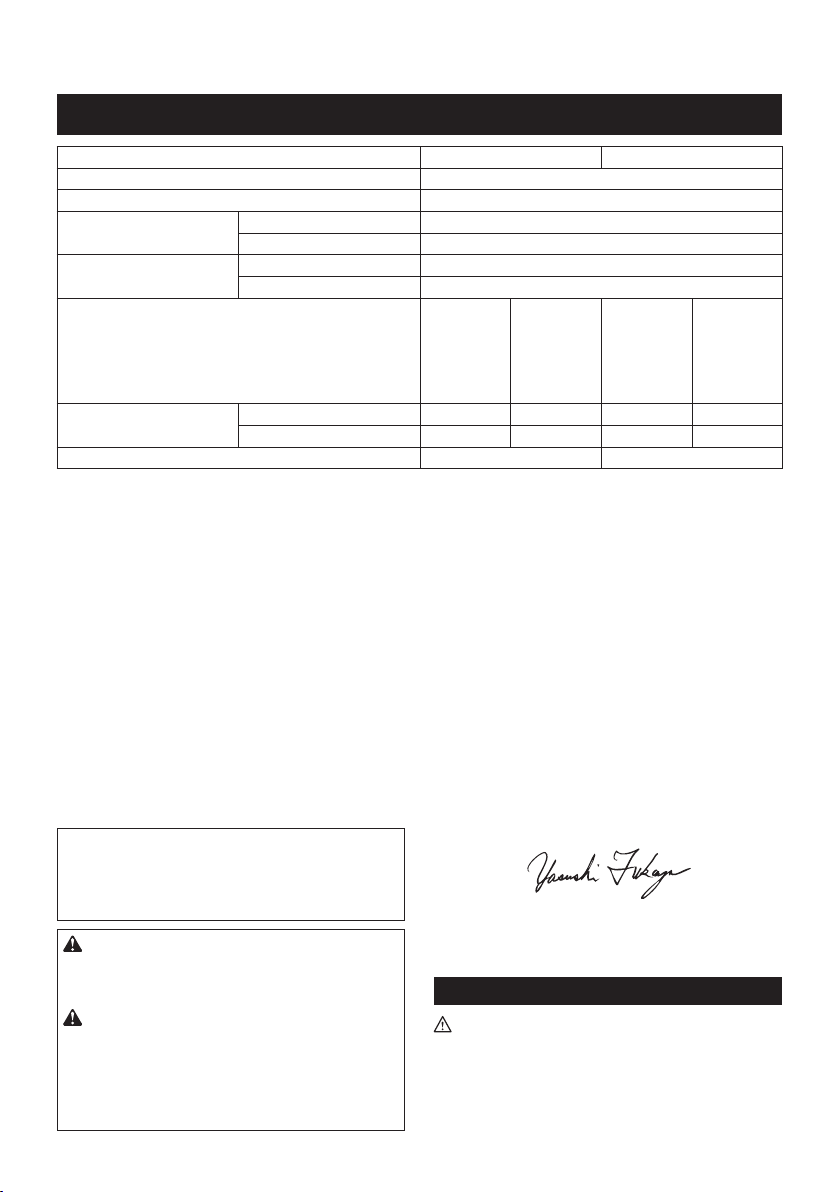

► Fig.17

Cut off the tip of the lm type pack.

Insert the lm type pack into the holder.

► Fig.18: 1. Rubber ring 2. Nozzle 3. Holder cap

Attach the rubber ring, the nozzle and the holder cap.

Make sure holder cap is tightened rmly.

Push the rod gently until the piston touches the bottom

of the lm type pack.

NOTE:

• Always check the lm type pack for puncture or

damage before installing. Do not use damaged

pack, otherwise the tool may be damaged.

Direct lling

NOTICE:

• Make sure the piston C is attached to the rod. Do

not use other type of piston for direct lling.

• Direct lling can only be performed with the long

holder (600ml).

Remove the holder cap, the nozzle and the rubber ring

from the holder.

Make sure the rod handle is placed at the most front position.

Dip the mouth of the holder into the caulking material.

Pull the rod handle slowly until required amount of

caulking material is lled in the holder.

Attach the rubber ring, the nozzle and the holder cap.

Make sure holder cap is tightened rmly.

NOTICE:

• Clean the holder with appropriate solvent after

every day's work. Otherwise adhered caulking

material may cause tool breakage.

OPERATION

CAUTION:

• Do not touch the rod during operation.

Otherwise your nger may be pinched between

the rod and the housing of the tool.

• Always wear goggles during operation.

NOTICE:

• Do not cover vents, or it may cause overheating

and damage to the tool.

• If you can not pull out the rod, turn the speed

adjusting dial to 1, and pull the switch trigger for a

moment, and try to pull the rod out after the motor

stopped. If the rod is still clogged, perform the

same action until the rod is able to move.

Cut off the tip of the nozzle suitable for individual oper-

ation. Be careful how much you cut the nozzle. The

diameter of the nozzle affects the amount of caulking

material dispensed.

Pull the trigger to dispense caulking material.

The amount of the caulking material dispensed is determined

by the trigger, the speed adjusting dial, the diameter of the

nozzle opening, caulking material type, and temperature.

It is recommended that the speed adjusting dial is set to

'1' and pull the trigger slowly at the rst time to test how

much amount of caulking material is dispensed.

When the rod reaches front end, the motor starts idling.

Replace the caulking material when it happens.

NOTE: If the caulking material is not dispensed,

check the following items:

• Nozzle tip is not cut adequately. Cut the nozzle

tip suitable for individual operation.

• Hardened material gets clogged in the nozzle.

Remove the hardened material.

• The cartridge is damaged. Replace the

cartridge.

• Caulking material is stiff. Warm the material until

it becomes soft.

• The wrong piston is used. Use appropriate

piston.