Models DTM41, DTM51 have been developed based on

the current BTM40/DTM40, BTM50/DTM50.

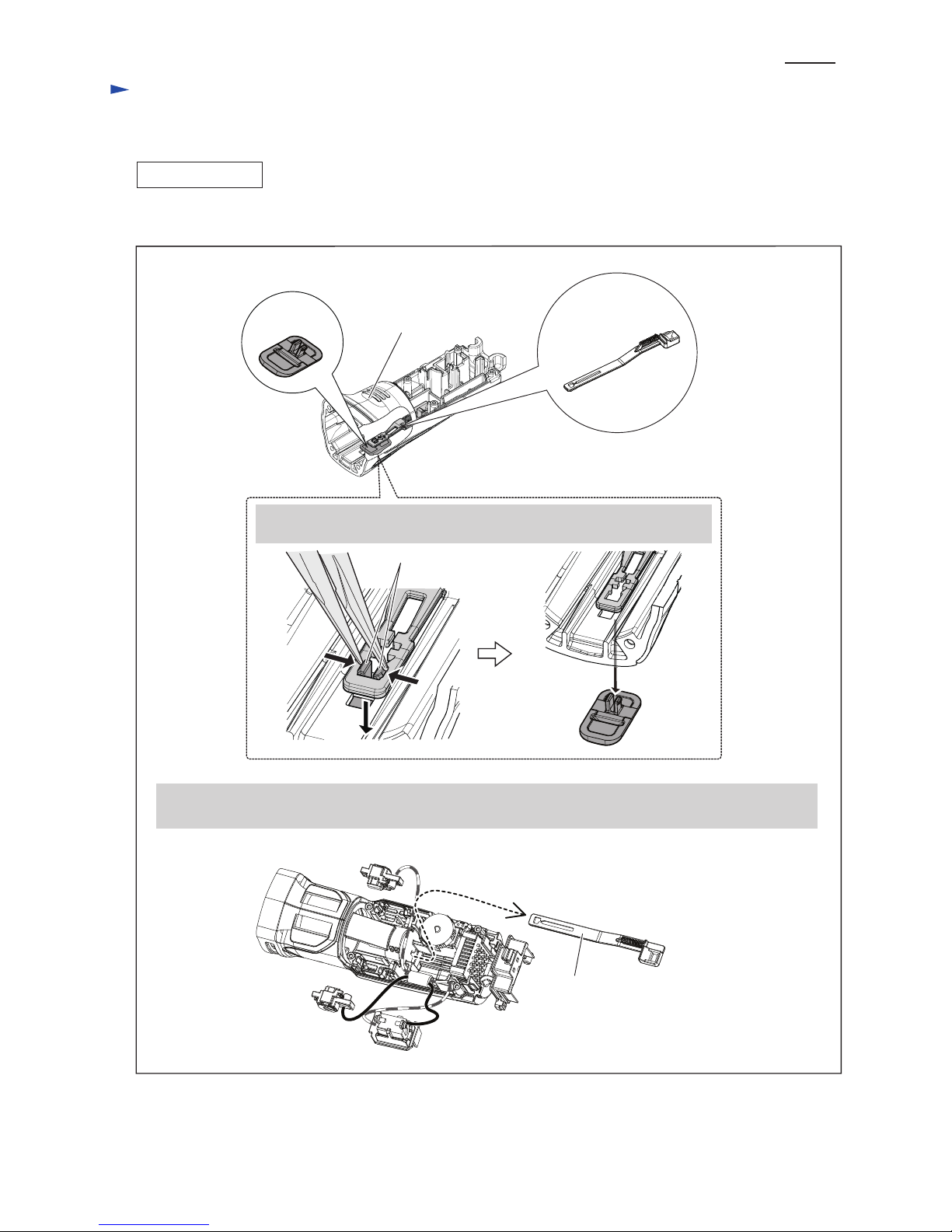

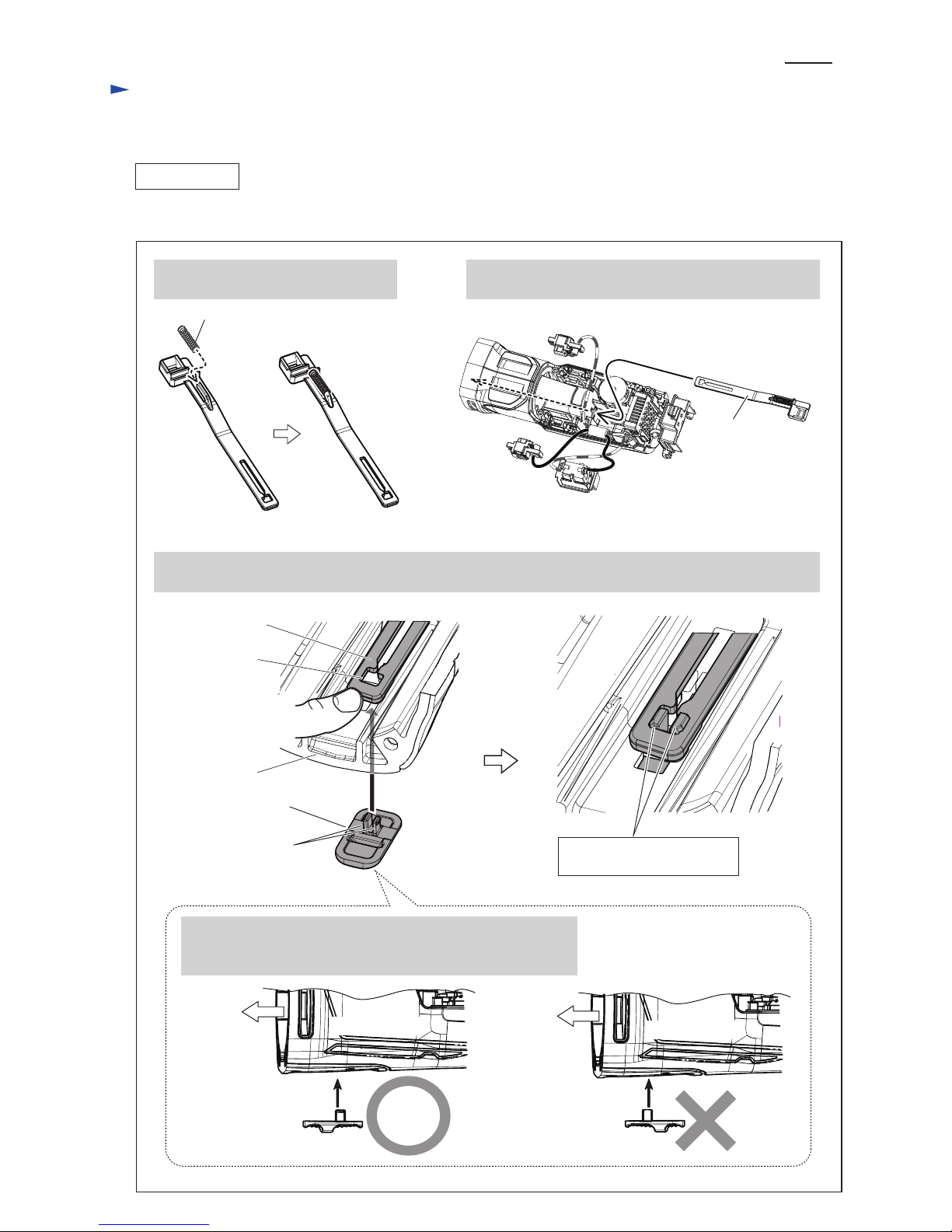

The two models feature the tool-less accessory change system,

in addition to the benefits of the current models.

These products are powered by the following Li-ion batteries:

DTM41 by 14.4V Li-ion batteries of BL1415 (1.3Ah)/ BL1415N,

BL1415NA (1.5Ah)/ BL1430 (3.0Ah), BL1430A (3.0Ah)/ BL1440 (4.0Ah)/

BL1450 (5.0Ah)

DTM51 by 18V Li-ion batteries of BL1815 (1.3Ah)/ BL1815N (1.5Ah)/

BL1820 (2.0Ah)/ BL1830 (3.0Ah)/ BL1840 (4.0Ah)/ BL1850 (5.0Ah)

DTM41, DTM51

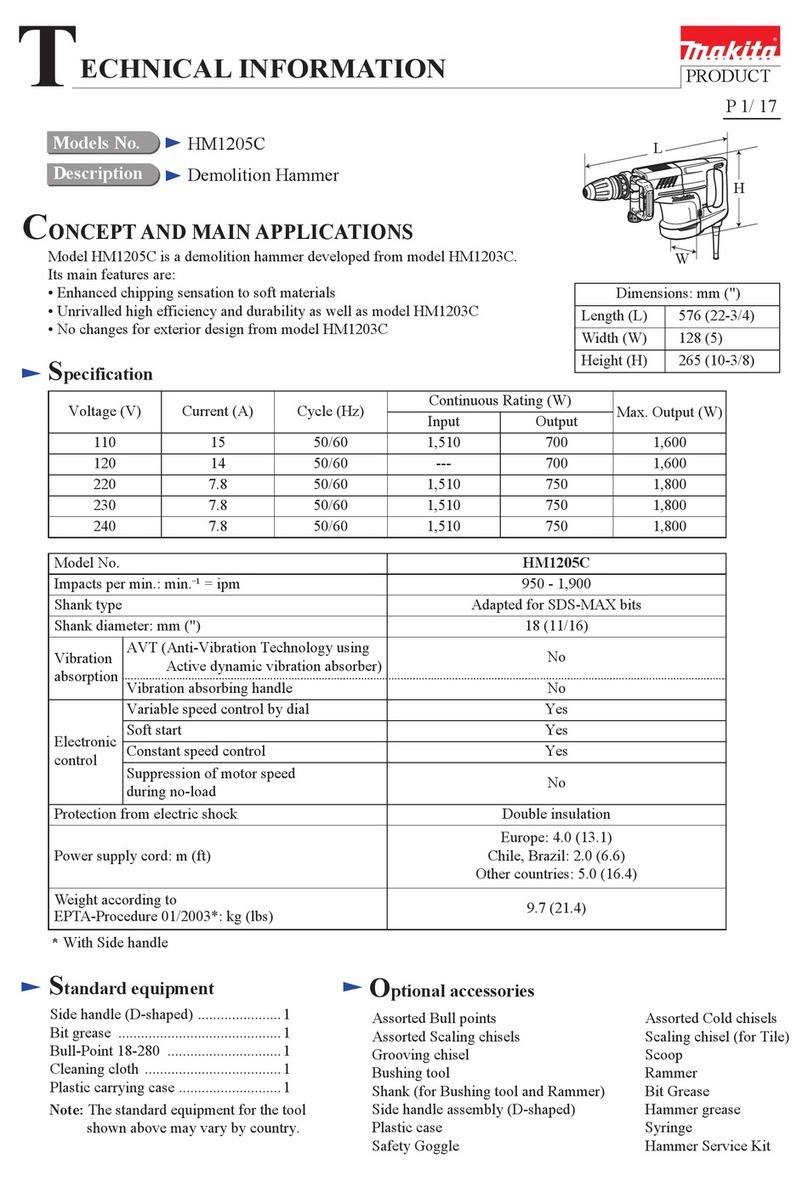

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 326 (12-7/8)*1/

340 (13-3/8)*2

80 (3-1/8)

122 (4-13/16)104 (4-1/8)

DTM51DTM41

Cordless Multi tools

Standard equipment

Note: The standard equipment may vary by country or model variation.

Oscillating multi tool accessories

[equivalent to BOSCH OIS (Oscillating Interface System)]

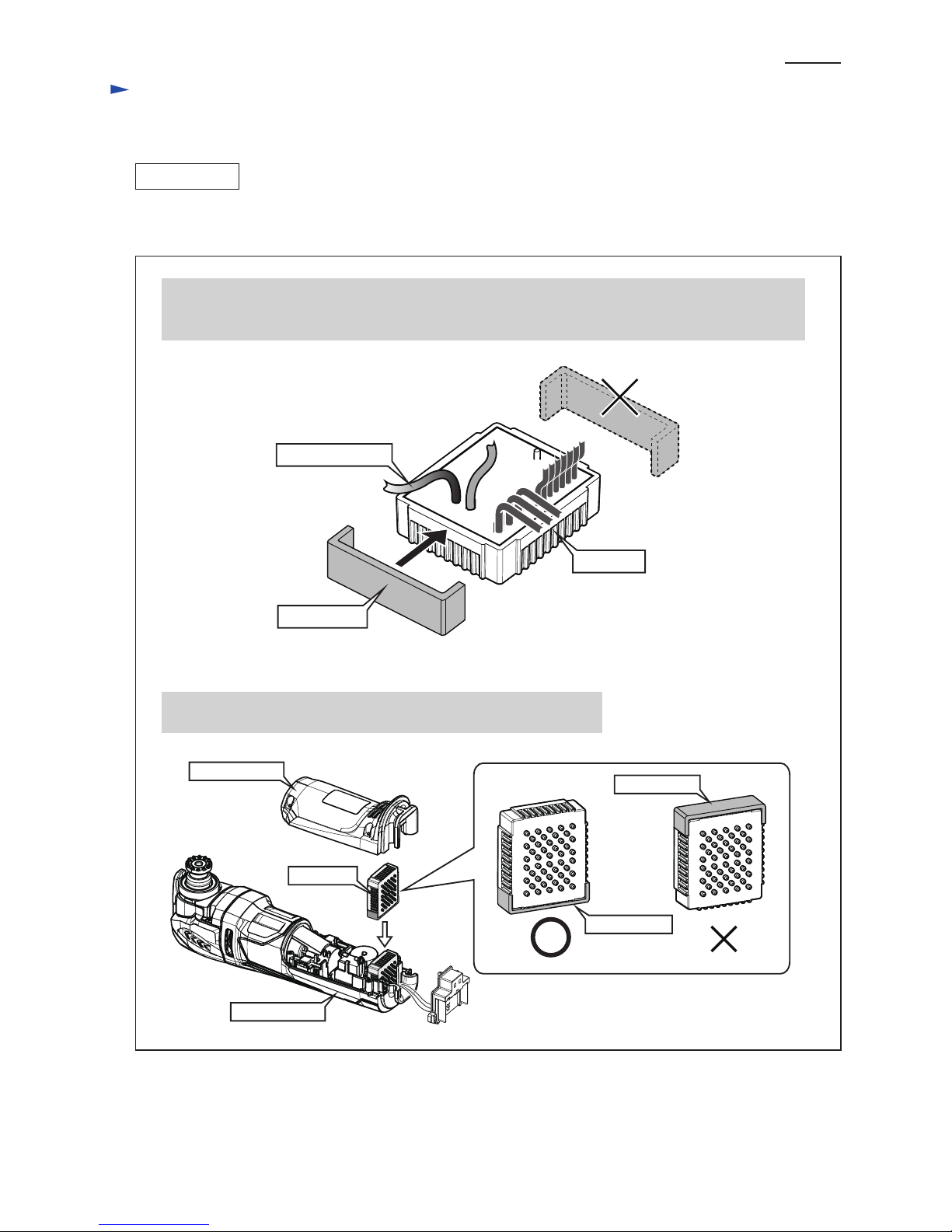

“Dust attachment” for Sanding pad (for European countries only)

“Tool box” for storing oscillating multi tool accessories (for some countries only)

Plastic carrying case or Tool bag (for some countries only)

Battery*8

Charger*8

Battery cover*9

Optional accessories

Weight according to

EPTA-Procedure 01/2003*3: kg (lbs)

2.0 (4.3)*4

2.1 (4.7)*5

2.0 (4.4)*6

2.2 (4.9)*7

YesVariable speed control by dial

Anti-restart function

Oscillations per minute: opm=minˉ¹

Oscillating multi tool accessories

*3 with Battery and Vacuum attachment, without Sanding pad

*4 With BL1415 or BL1415N *5 With BL1430, BL1440 or BL1450

*6 With BL1815, BL1815N or BL1820 *7 With BL1830, BL1840 or BL1850

6,000 - 20,000

Oscillation angle, left/right: degree [°] 1.6 (3.2 total)

Makita oscillating multi tool accessories

equivalent to BOSCH OIS (Oscillating Interface System)

Soft start Yes

Electronic

control

Yes

Oscillating multi tool accessories

[equivalent to BOSCH OIS (Oscillating Interface System)]

Triangular abrasive papers (Hook & loop type)

Tool box (for storing oscillating multi tool accessories)

Dust attachment set

Li-ion battery BL1415 (for DTM41)

Li-ion battery BL1415N (for DTM41)

Li-ion battery BL1415NA (for DTM41)

Li-ion battery BL1430 (for DTM41)

Li-ion battery BL1440 (for DTM41)

Li-ion battery BL1450 (for DTM41)

Li-ion battery BL1815 (for DTM51)

Li-ion battery BL1815N (for DTM51)

Li-ion battery BL1820 (for DTM51)

Li-ion battery BL1830 (for DTM51)

Li-ion battery BL1840 (for DTM51)

Li-ion battery BL1850 (for DTM51)

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Four port multi charger DC18SF

Automotive charger DC18SE

PRODUCT

P 1/ 12

DTM41*2

W

L

H

Specification Model

Battery

Cell

Voltage: V

Capacity: Ah

Li-ion

14.4 18

DTM41 DTM51

Max output: W 390340

Energy capacity: Ah

Charging time (approx.): min.

DTM51*2

*8: Battery and charger are not supplied with “Z” model *9: Supplied with the same quantity of extra Battery

TECHNICAL INFORMATION

1.3, 1.5, 2.0, 3.0, 4.0, 5.01.3, 1.5, 3.0, 4.0, 5.0

24, 27, 36, 54, 72, 9019, 22, 44, 58, 72

15, 15, 24, 22, 36, 45 with DC18RC15, 15, 22, 36, 45 with DC18RC

OFFICIAL USE

for ASC & Sales Shop

*1 With BL1815, BL1815N or BL1820/

BL1415 or BL1415N

*2 With BL1830, BL1840 or BL1850/

BL1430, BL1440 or BL1450