Makita DHR182ZU User manual

Other Makita Power Tools manuals

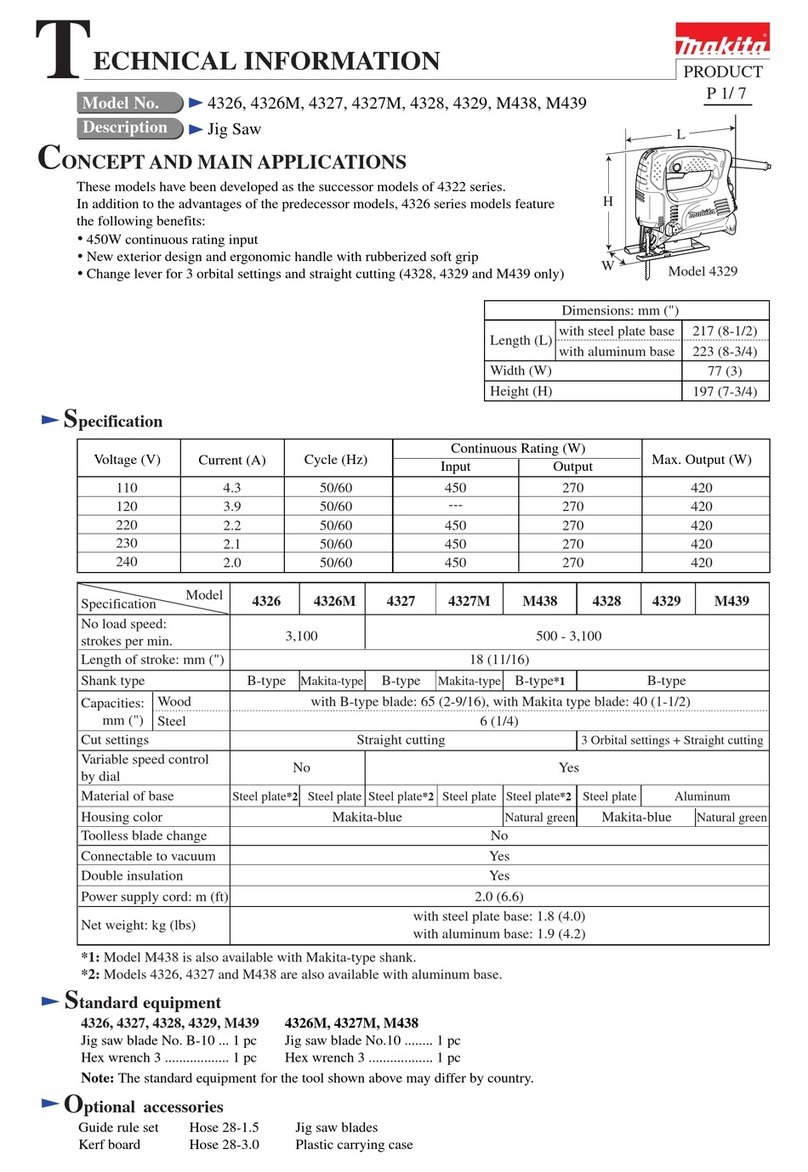

Makita

Makita 3606 User manual

Makita

Makita DSC163 User manual

Makita

Makita DHK180 User manual

Makita

Makita CG100D User manual

Makita

Makita 903D User manual

Makita

Makita Makstar BVR340 User manual

Makita

Makita JS1300 User manual

Makita

Makita DTW250 User manual

Makita

Makita DHR280 User manual

Makita

Makita HM1213C User manual

Makita

Makita HM1304B User manual

Makita

Makita HK1820 User manual

Makita

Makita bst110 User manual

Makita

Makita AN454 User manual

Makita

Makita DCG140 User manual

Makita

Makita 6805BV User manual

Makita

Makita BHP343 User manual

Makita

Makita M9800 Series User manual

Makita

Makita HK1820L User manual

Makita

Makita HM1214C User manual