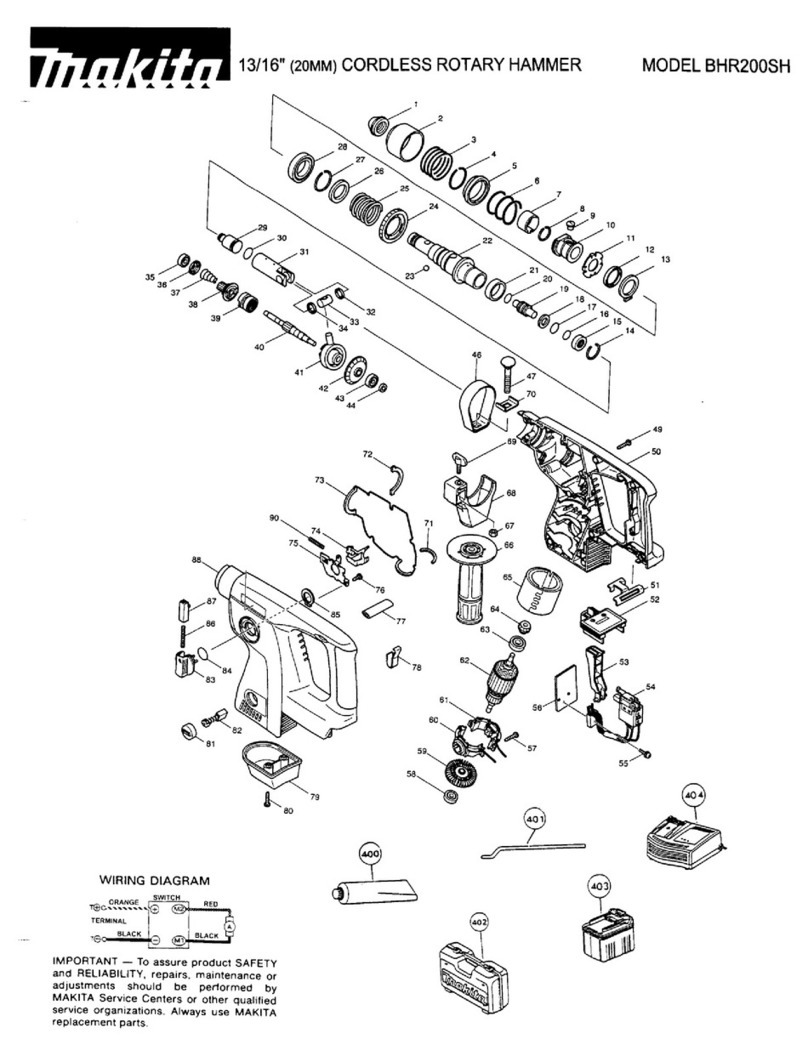

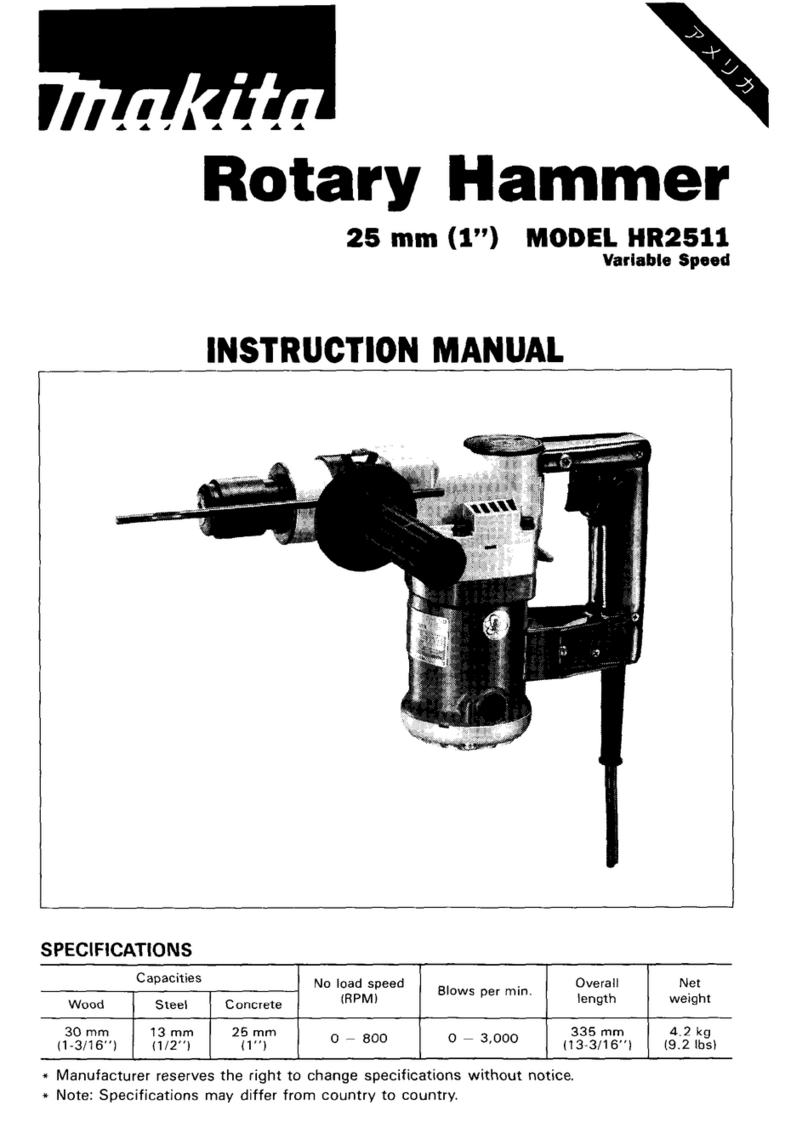

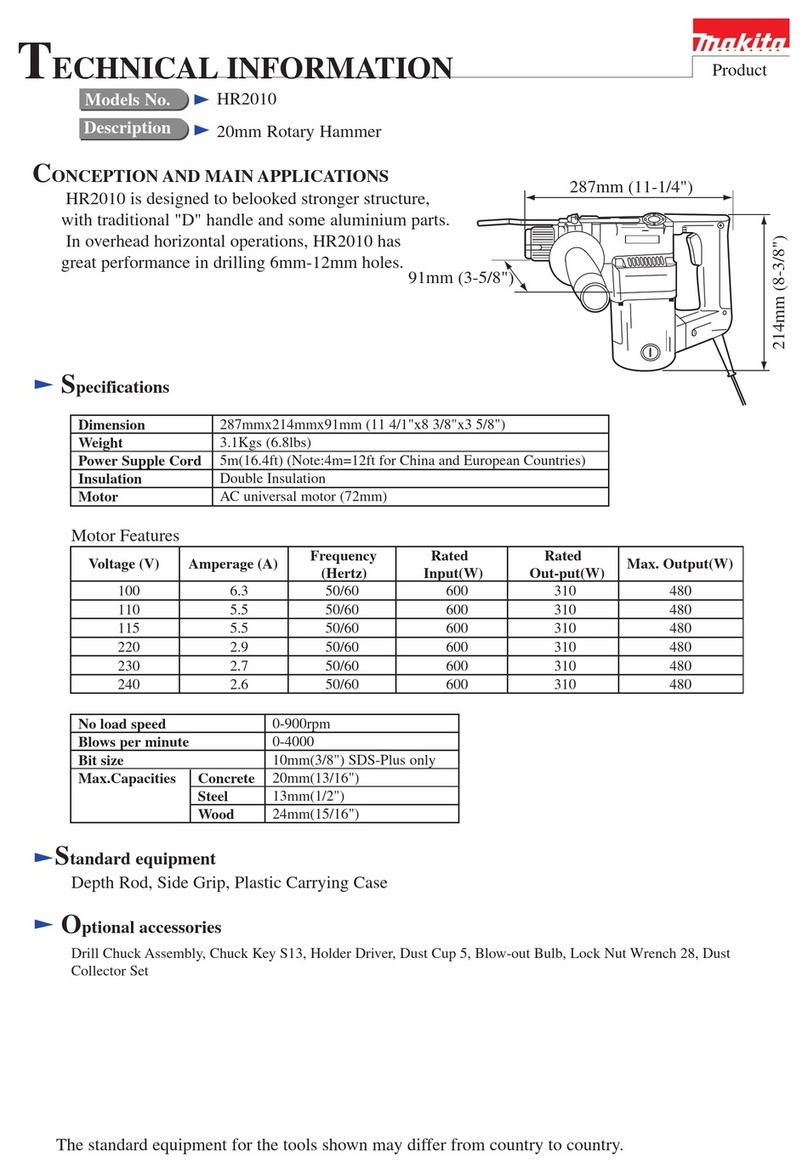

Specifications

CONCEPTION AND MAIN APPLICATIONS

Models No.

Description

PRODUCT

P 1 / 16

Dimensions : mm ( " )

Width (W)

Height (H)

Length (L)

118mm (4-5/8")

488mm (19-1/4")

For matured line-up of SDS-Max Rotary Hammers, Model HR4500C

has been developed as a sister model to HR4000C(40mm;1-3/4") and

HR5001C(50mm;2") which are already popular to users around the

world.

HR4500C

Rotary Hammer 45mm (1-3/4")

278mm (11")

Continuous Rating (W)

Voltage (V) Current (A) Cycle (Hz) Input Output Max. Output(W)

120

110 13 50/60 1,300 600 1,500

100 15 50/60 1,300 600 1,500

13 50/60 1,250 600 1,500

1,500

1,500

1,500

220 6.6 50/60 1,300 600

230 6.6 50/60 1,300 600

240 6.8 50/60 1,300 600

TECHINICAL INFORMATION

Performing excellent drilling in concrete within the diameter range

from 25mm(1") to 45mm(1-3/4"), it also has the same features and

benefits as HR4000C and HR5001C.

Hammer Grease (30cc), Blow-out Bulb, Dust Cup 5, Dust Cup 9, Bull Point, Cold Chisel, Scaling Chisel,

Clay Spade, Bushing Tool, Rammer, Safety Goggles, Core Bit Adapter,

Core Bits; Hole diameter : 20mm(13/16"), 30mm(1-3/16"), 35mm(1-3/8"), 40mm(1-9/16"), 45mm(1-3/4"),

54mm(2-1/8"), 65mm(2-9/16"), 79mm(3-1/8"), 105mm(4-1/8"), 118mm(4-5/8")

Tungusten-carbide Tipped Bits; Bit diameter : 10mm(3/8"), 10.5mm(7/16"), 11mm(7/16"), 12mm(15/32"),

12.5mm(1/2"), 12.7mm(1/2"), 13.5mm(1/2"), 14.3mm(9/16"),

14.5mm(9/16"), 16mm(5/8"), 17mm(11/16"), 17.5mm(11/16"),

18mm(11/16"), 19mm(3/4"), 20mm(13/16"), 21.5mm(7/8"),

22mm(7/8"). 24mm(15/16"), 25mm(1"), 25.4mm(1"), 26mm(1"),

28mm(1-1/8"), 30mm(1-3/16"), 32mm(1-1/4"), 35mm(1-3/8"),

38mm(1-1/2")

120 - 240

1,250 - 2,550

SDS-Max shank bit

18 (11/16")

No load speed Rotations per minute : rpm=min-1

Blows per minute : bpm=min-1

Bit type

Diameter of shank : mm (")

Drilling capacities

: mm (")

Net weight : Kg (lbs)

Cord length : m (ft)

7.8 (17.2)

Standard spec. : 5 (16.4)

European spec. : 4 (13.1)

STANDARD EQUIPMENT

45 (1-3/4")

Tungusten-carbide

tipped bit

Core bit 125 (4-7/8")

Grip 36 Assembly

(Bar style side handle) ------------ 1pc.

Depth Gauge ----------------------- 1pc.

Grease Vessel (Bit Grease) ------- 1pc.

Plastic Carrying Case ------------- 1pc.

Side Handle Assembly

(D-shaped side handle) ----------- 1pc.

OPTIONAL ACCESSORIES

The standard equipment for the machine may differ from country to country.

See next page for detailed information.

L

W

H