10 ENGLISH

ENGLISH (Original instructions)

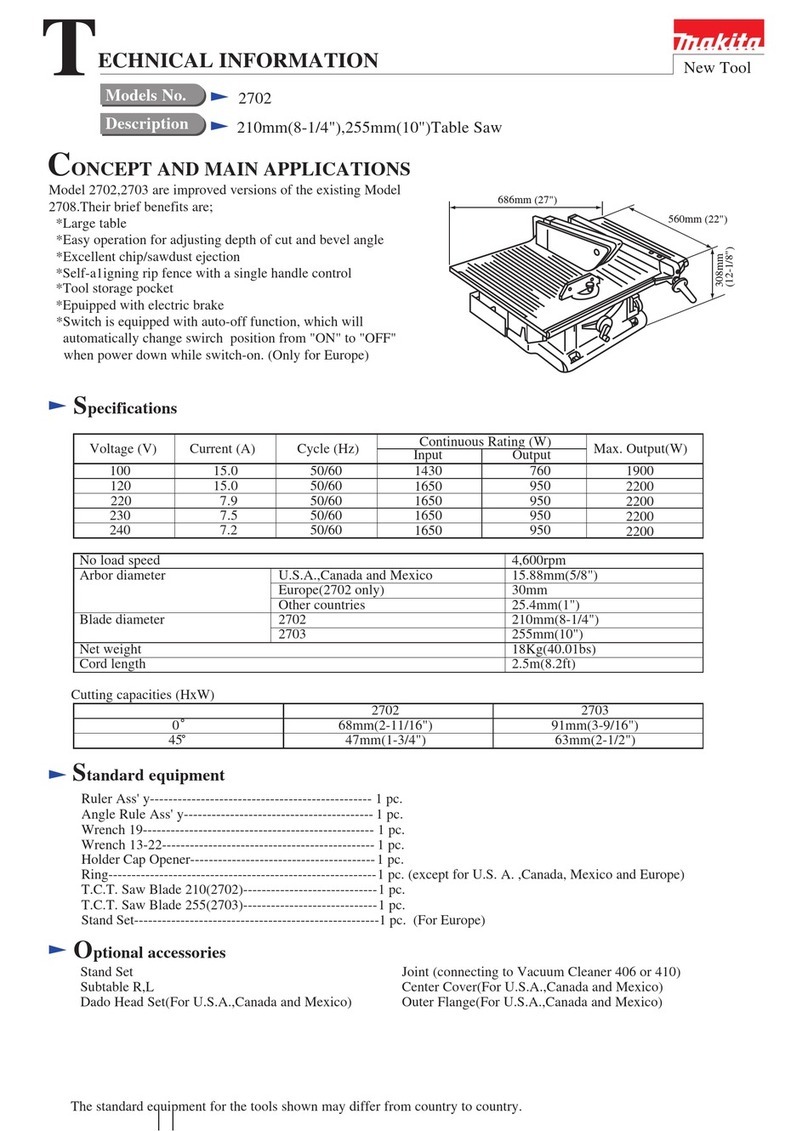

SPECIFICATIONS

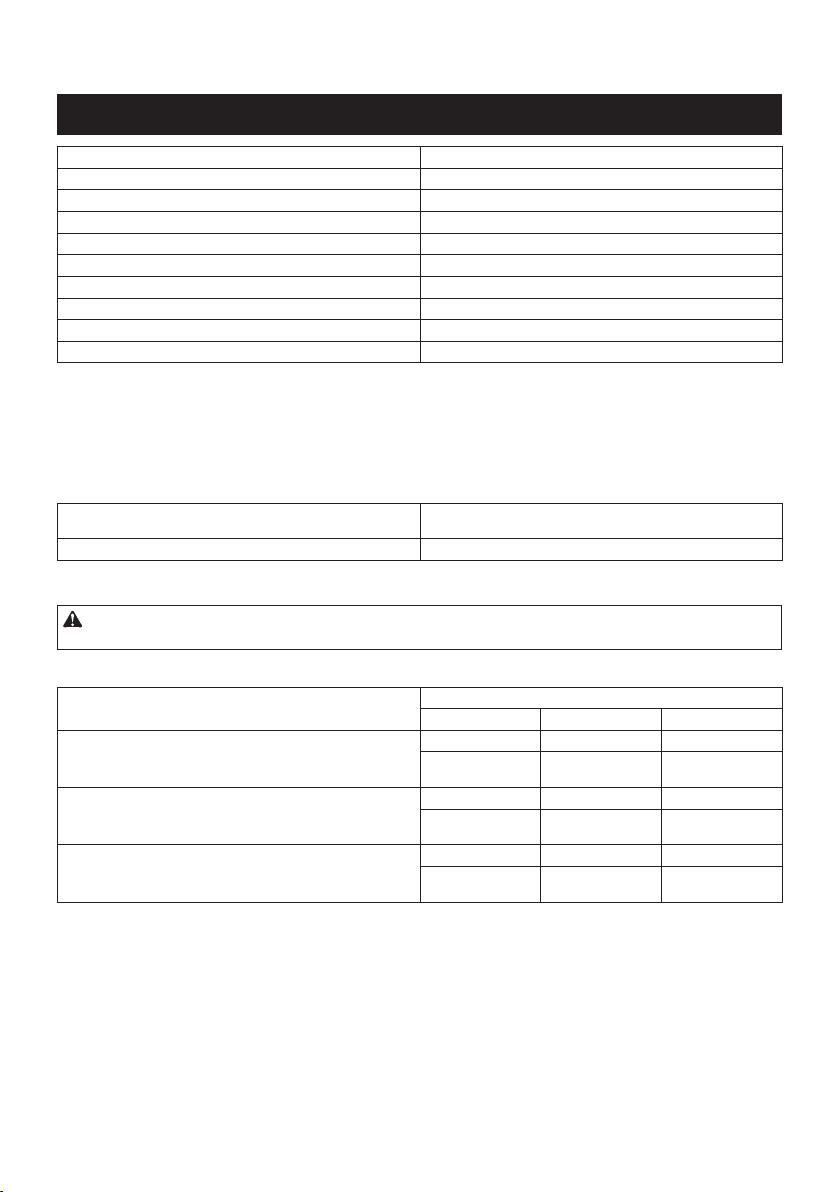

Model DLS713

Blade diameter 190 mm

Hole (arbor) diameter (country specic) 20 mm or 15.88 mm

Max. kerf thickness of the saw blade 2.2 mm

Max. Miter angle Left 47° , Right 57°

Max. Bevel angle Left 45°, Right 5°

No load speed 2200 min-1

Dimensions (L x W x H) 655 mm x 430 mm x 454 mm

Net weight 12.2 - 14.3 kg

Rated voltage D.C. 18 V

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heavi-

est combination, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

Battery cartridge BL1815N / BL1820 / BL1820B / BL1830 / BL1830B / BL1840 /

BL1840B / BL1850 / BL1850B / BL1860B

Charger DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF

• Some of the battery cartridges and chargers listed above may not be available depending on your region of

residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

and chargers may cause injury and/or re.

Max. Cutting capacities (H x W) with blade 190 mm in diameter.

Miter angle Bevel angle

45° (left) 0° 5° (right)

0° 25 mm x 300 mm 52 mm x 300 mm 40 mm x 300 mm

----- * 60 mm x 265 mm

(Note 1)

-----

45° (left and right) 25 mm x 212 mm 52 mm x 212 mm -----

----- * 60 mm x 185 mm

(Note 2)

-----

57° (right) ----- 52 mm x 163 mm -----

----- * 60 mm x 145 mm

(Note 3)

-----

(Note)

* mark indicates that a wood facing with the following thickness is used.

1: When using a wood facing 20 mm thickness

2: When using a wood facing 15 mm thickness

3: When using a wood facing 10 mm thickness