Makita LS1016 User manual

Other Makita Saw manuals

Makita

Makita XSL08 User manual

Makita

Makita DJR186 User manual

Makita

Makita LS1219 User manual

Makita

Makita HS6101 User manual

Makita

Makita 2704 User manual

Makita

Makita DJR187 User manual

Makita

Makita 5201NA Manual

Makita

Makita LS0714L User manual

Makita

Makita 2704 User manual

Makita

Makita 5604R User manual

Makita

Makita JR3000VT User manual

Makita

Makita DSD180 User manual

Makita

Makita DLS211 User manual

Makita

Makita 2416S User manual

Makita

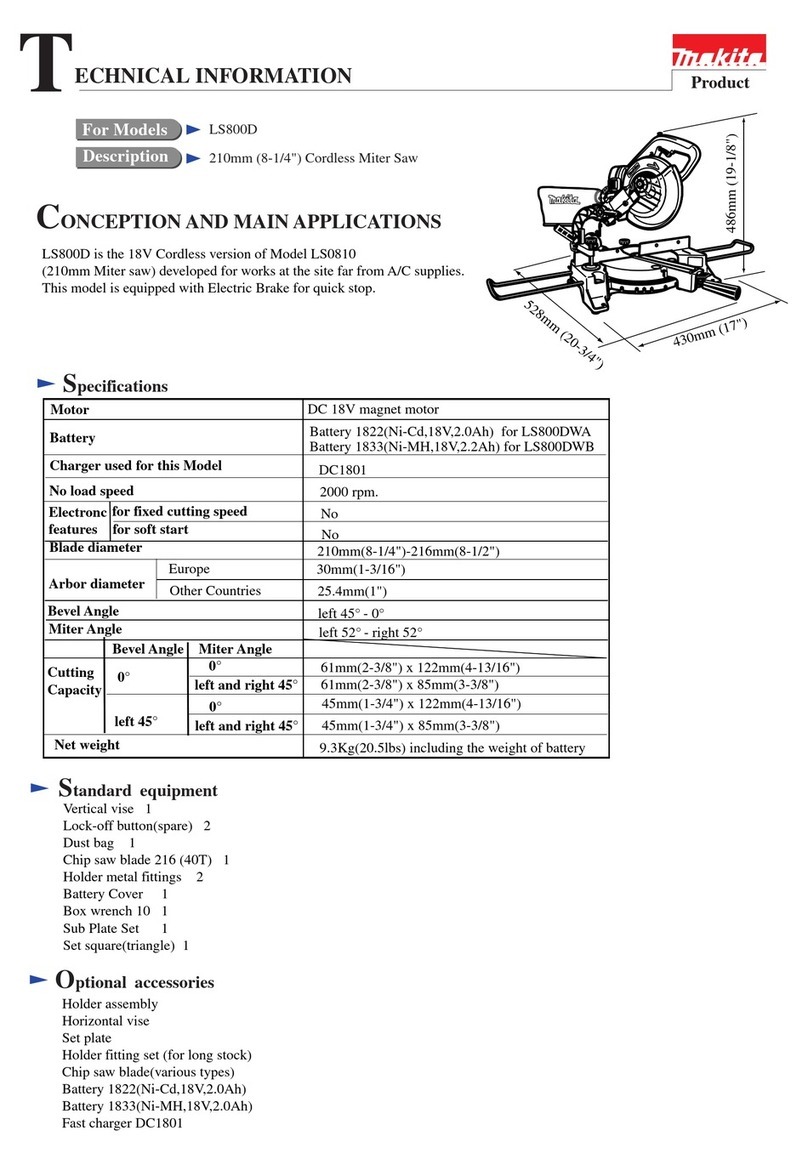

Makita LS800D Manual

Makita

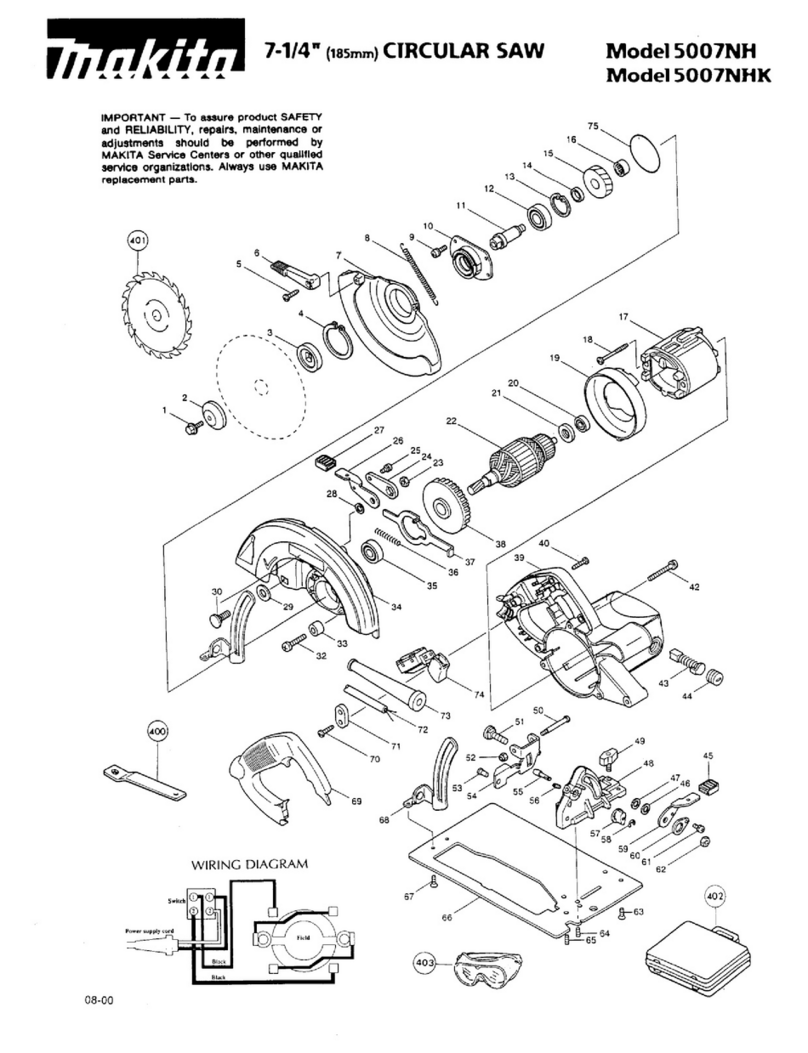

Makita 5007NH Quick start guide

Makita

Makita DUC101 User manual

Makita

Makita LS0714 User manual

Makita

Makita MLT100N User manual

Makita

Makita DJR183 User manual