.

.i

I

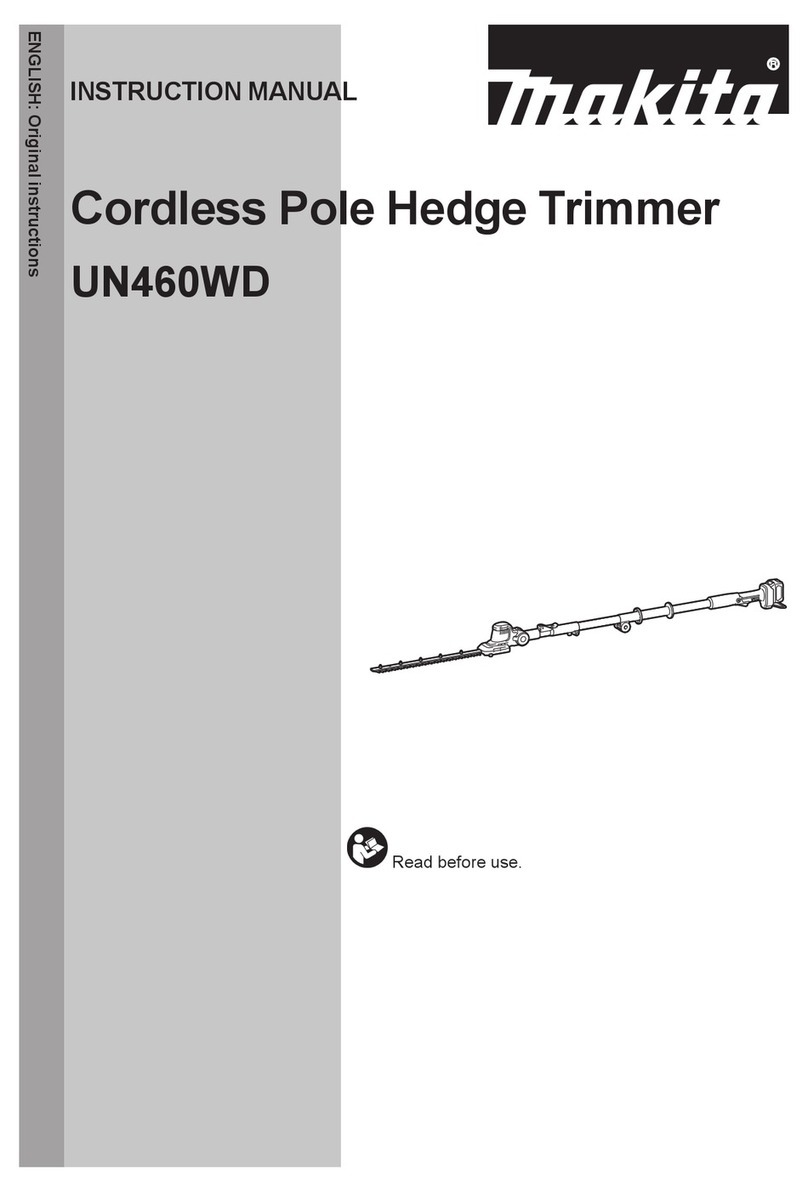

Starting the Pole Hedge Trimmer

-

At all times allow

a

15-meterdiameter safely zone around the working area.

Make

sure

that

all

persons (in particular children)and/or animals remain outside

this zone. In general, avoid using the hedgetrimmer whenever people (in

particular children) are nearby.

safe

operational condition.

should have

a

smoothand easyaction.

Make

sure

that the

lock-off

lever

functions properly. Check that the handles

are

clean and dry and testthe

STOP

switch

to

ensure that it

is

functioning properly.

-

Beforestartingthe Pole Hedge Trimmer,always make

sure

that the machine

is

in

-

Check the operation

of

the throttle lever safety mechanism.

The

lack-off lever

Always start the pole hedgetrimmer in accordancewith the directions provided in

thisinstruction manual.

Follow the instructions below to start the pole hedgetrimmer

-

Start

the pole hedge trimmer onlyafter the machine hasbeen completely

assembled and

all

accessory

parts have been attached.

-

Before startingthe engine, make surethat cutter blades are not obstructed by

anyforeign

objects

such

as

stones, branches, etc.

-

Stoptheengine immediately

if

engine problems occur.

-

When operating

the

pole hedge trimmer,always maintain

a

firm grip on both

handles. Wrap your fingerstightlyaround each handle, cradling the handle

between thumb andforefinger.To keep the

pole

hedge trimmer under control at

all

times, avoid changingyour gripduring operation. Make surethatthe control

handles

are

in good condition andfree

of

moisture, mud, oil

or

grease.

Always ensure secureand well-balanced footing

-

Only

use

the pole hedgetrimmer outdoors.

-Alwaysstopthe engine immediately and discontinue operation

if

enginetrouble

occurs

or

if

the machine startsmaking unusual noise.

-

Exhaust fumesarepoisonous. Never operate the machine in an enclosed room

or

tunnel without ventilation [risk

of

suffocation and gas poisoning). Notethat

carbon monoxide

is

an

odorless

gas. Always make

sure

that areas where the

engine

is

operated

are

adequatelyventilated.

-

Stopthe engine when resting, or when the pole hedgetrimmer

is

left

unattended.

Place

the machine in

a

safe

locationand makesurethat no

combustible material

is

nearby.

-

Never place

a

hot hedgetrimmer onto

dry

grassor combustiblematerial.

-

To reduce the

risk

of

fire,

keepthe engine and muffler

free

of

debris,

leaves

or

-

Never operatethe engine

if

the muffler

is

malfunctioning.

-

Turn

off

the engine

before

transportation.

-Alwaysstopthe engine in the followingcircumstances. When:

excessivelubricant.

Resting

Transporting the machine

Cleaning

the

machine

Refuelingthe machine

Performingmaintenance onthemachine

Fixing

a

problem with the machine

-

When transporting the machine in

a

vehicle, always securely

attach

the

pole

hedge trimmer to avoid leakage

of

residual fuel.

-Alwaysempty the

fuel

tank before transporting the pole hedgetrimmer in

a

vehicle.

-When unloading the machine from

a

vehicle,

take

extra

care

not tadrop the pole

hedgetrimmer

to

the ground,

as

this may seriouslydamagethe

fuel

tank.

-

Except in

an

emergency, never dropthe pole hedgetrimmer

as

this may

seriously damagethe machine.

-When transporting the pole hedgetrimmer, always lift the machine completely

off

of the ground. Never drag

the

engine acrossthe ground

as

this may damage the

fuel

tank and possibly

cause

a

fire.

of

the pole hedgetrimmer during transportation and storage.

-

Always

use

the

cutter

cover provided to protect and

secure

the cutting section

Resting

Transporting the machine

Cleaningthe machine

Refueling

the

machine

Performing maintenance

on

the

machine

Fixing

a

problem with

the machine

I

n

I

4